A support shear differential compensation connection device

A technology for connecting devices and repairing boards, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as lengthening the test cycle, potential safety hazards of equipment and personnel, and flawed test results, so as to reduce the test cycle and test cost. Ensure accuracy and completeness, avoid rework effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

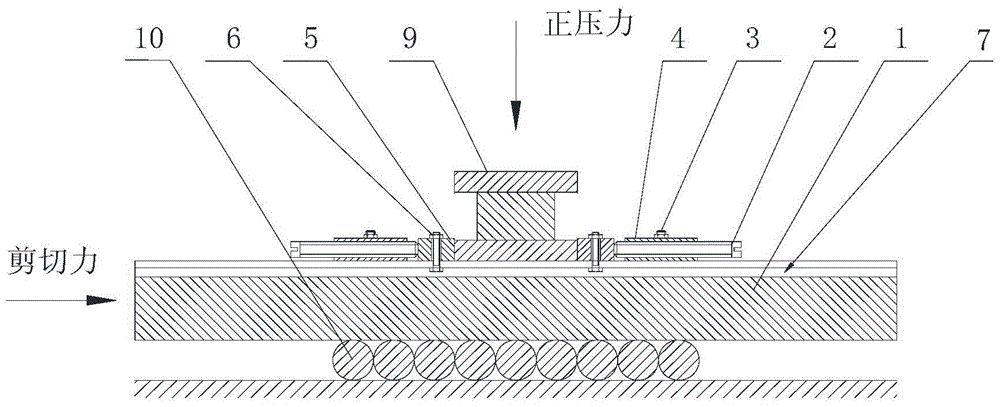

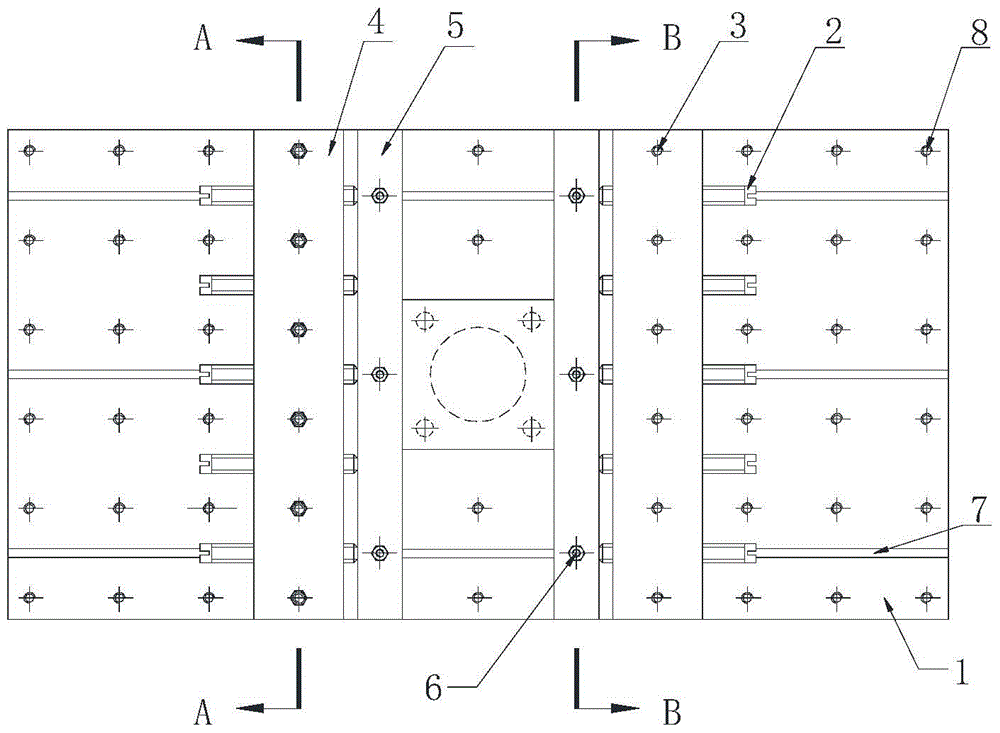

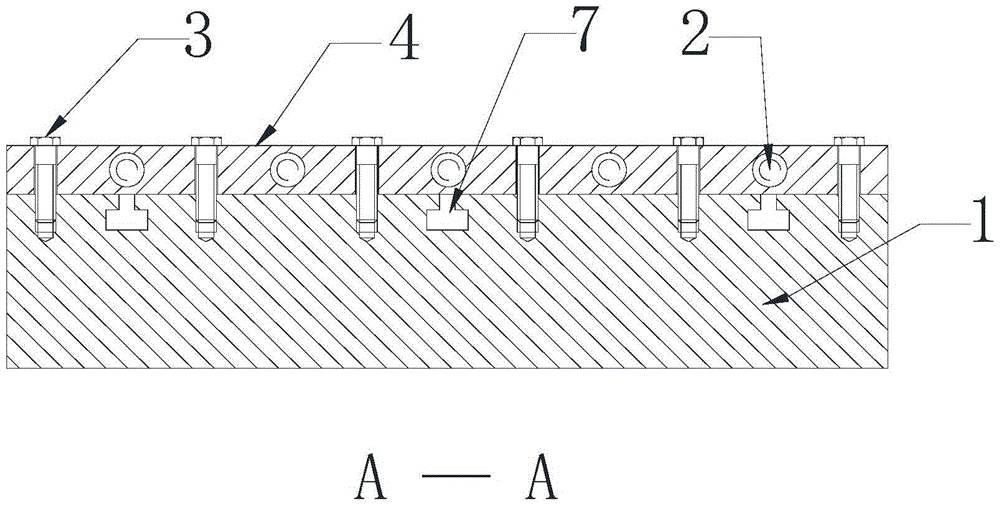

[0017] Such as figure 1 The shown one kind of support anti-shear differential compensation connection device includes shear slide plate 1, jacking bolt 2, anchor plate bolt 3, anchor plate 4, differential compensation plate 5, differential compensation bolt 6, dovetail groove 7, anchor Bolt holes 8; evenly distributed anchor bolt holes 8 are arranged on the shear slide 1; two anchor plates 4 are laid on the shear slide 1, and are fixed on the shear slide 1 by the anchor plate bolts 3; The difference patching plate 5 is placed between the test supports 9; the anchor plate 4 is provided with a threaded through hole along the shearing direction, and the jacking bolt 2 is screwed in through the threaded through hole, and the difference patching plate 5 is pressed tightly to provide shear for the test of the support 9. Cut reaction force.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com