Piston ring detection method based on monocular vision detection

A piston ring and edge detection technology, applied in the direction of measuring devices, image data processing, instruments, etc., can solve problems such as piston ring roundness measurement without considering sub-pixel data processing, affecting the quality of detection, affecting the measurement accuracy, etc., to achieve Expand the scope of measurement, improve the quality of detection, and improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

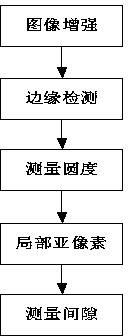

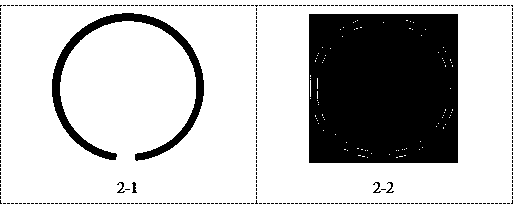

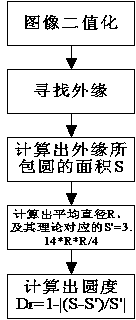

Method used

Image

Examples

Embodiment Construction

[0032] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Piston ring measurement system of the present invention consists of Figure 4 As shown, it is mainly composed of the measured object (piston ring), optical imaging system, CCD camera, image acquisition card and computer system. The CCD camera converts the optical signal with size information into a video signal and inputs it to the computer system for processing. When measuring, the data firstly obtained by the present invention is expressed in units of pixels. If the actual size of the piston ring is to be obtained, the corresponding relationship between the image pixels and the actual size must be established, that is, the calibration of the measurement system. In the present invention, adopted relative calibration method, i.e. the standard part method, by measuring the pixel size of the standard part, and because the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com