Air source heat pump unit with parallel double compressors

An air source heat pump and dual compressor technology, applied in compressors, refrigerators, refrigeration components, etc., can solve the problems of difficult promotion, strict piping requirements, and increased costs, and achieve a simple oil return method, low cost, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

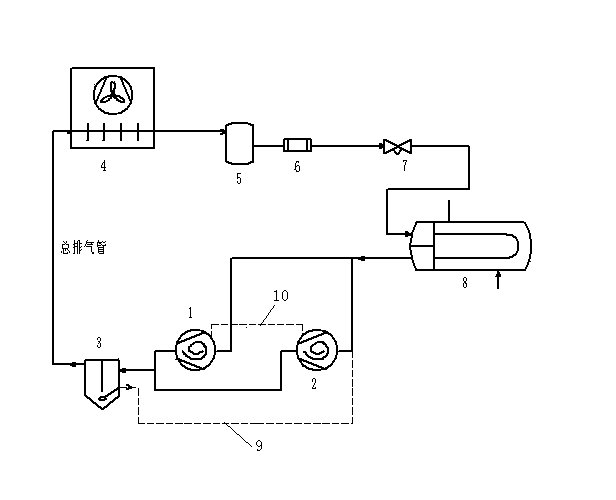

[0011] see figure 1 , the present invention includes a condenser 4, a liquid receiver 5, a dry filter 6, a thermal expansion valve 7 and an evaporator 8 connected in sequence. The suction pipe at the outlet of the evaporator 8 is respectively connected to the inlets of compressor one 1 and compressor two 2, and the total exhaust pipe at the outlet of compressor one 1 and compressor two 2 is connected to the oil separator 3, and from the oil separator 3. The separated oil is returned to the inlet of compressor 2 through oil return pipe 9. An oil equalizing pipe 10 is connected between the first compressor 1 and the second compressor 2, and the outlet of the oil separator 3 is connected to the inlet of the condenser 4 to form a circulating refrigeration system. The difference between the suction resistance of compressor 1 and the suction resistance of compressor 2 is ≥ 0.3 bar, so that there is a pressure difference in the oil tanks of the two compressors.

[0012] When the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com