Roller brush speed control system for pavement sweeping machine

A sweeper and roller brush technology, applied in road cleaning, mechanical equipment, cleaning methods, etc., can solve problems such as low speed, and achieve the effect of strong practicability and advancement, and a wide range of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

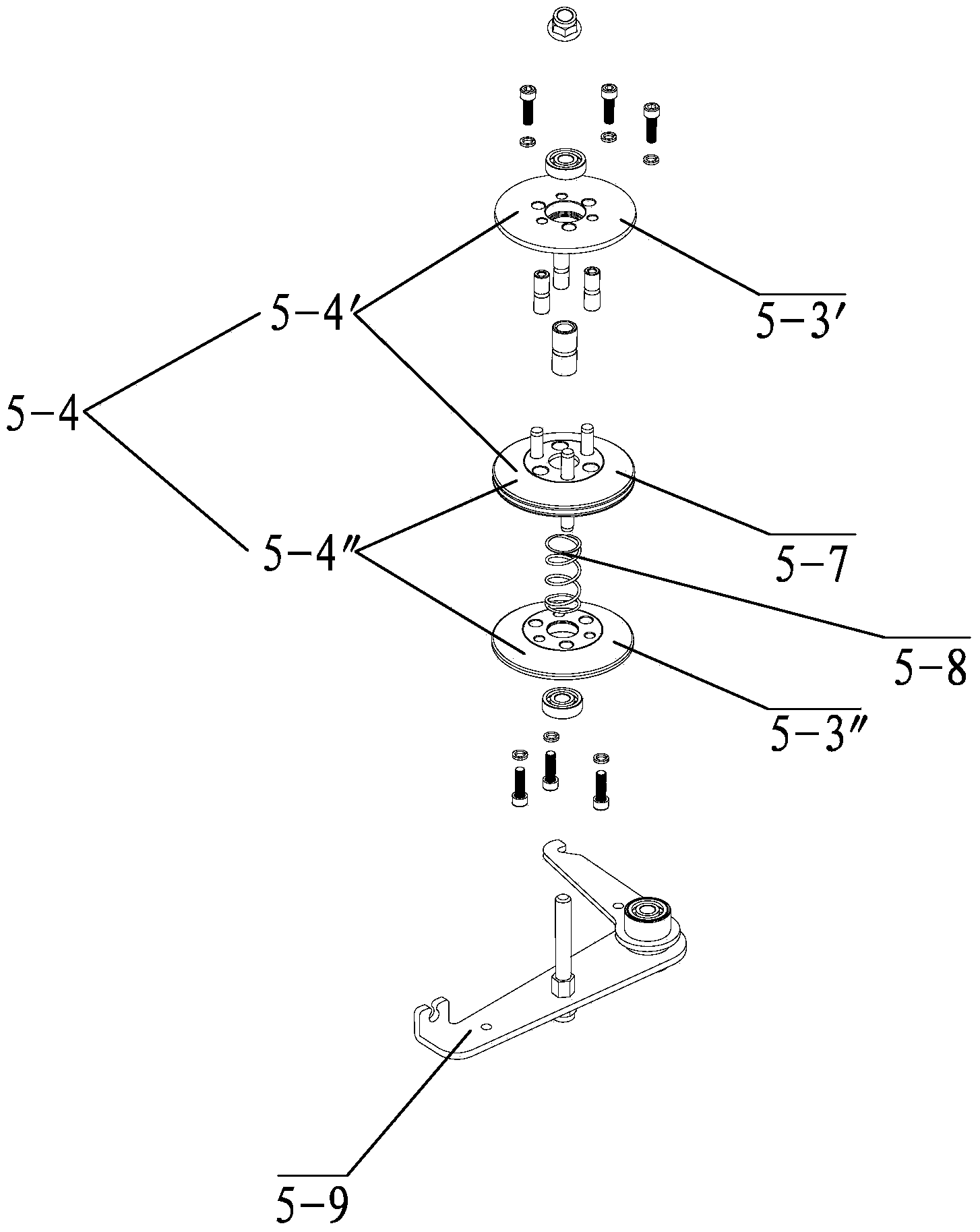

[0016] Such as figure 1 , 2 , 3, 4, and 5, what the present invention discloses is a roller brush speed change system for a road sweeper, including a drive pulley 3, a belt clutch control assembly 4, a variable speed pulley control assembly 5, a roller brush pulley 11, a roller Brush variable speed control assembly 1 and roller brush starting assembly 2; wherein, the variable speed pulley control assembly 5 includes an upper pulley 5-4' and a lower pulley 5-4" that rotate around the same central axis The pulley group 5-4, the drive pulley 3 is connected with the lower pulley 5-4" through the primary transmission belt 9, and the roller brush pulley 11 is connected with the upper pulley 5-4' through the secondary transmission belt 10; the belt clutch control assembly 4 is located on the primary transmission belt 9, the roller brush starting assembly 1 is connected through the first cable 12 and controls the belt clutch control assembly 4, and the variable speed pulley control a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com