Engine turbocharger

A turbocharger and engine technology, which is applied in the field of engine turbocharger exhaust gas release device, can solve the problems of inability to linear control, low control accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same parts.

[0029] In this article, "schematic" means "serving as an example, example or illustration", and any illustration or implementation described as "schematic" should not be interpreted as a more preferred or more advantageous Technical solutions. Herein, "a" not only means "only one", but also means "more than one".

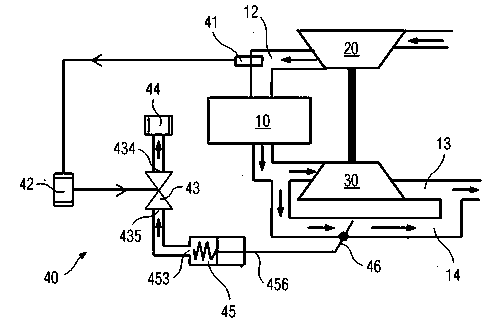

[0030] Such as figure 1 As shown, the engine turbocharger includes a compressor 20, a turbine 30, bypass line 14 and an exhaust gas bleeder. The compressor 20 is connected to the intake pipe 12 of the engine body 10 , and the turbine 30 is connected to the exhaust pipe 13 of the engine body 10 and is coaxial with the compressor 20 . The bypass line 14 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com