L800*76 efficient transmission spiral drill rod and parameter optimizing method

A technology of auger drill pipe and optimization method, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of increased difficulty in parametric design of auger drill pipe, complex force of coal particles, etc., and achieve the goal of improving coal delivery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

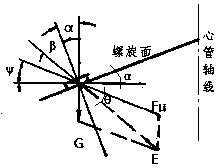

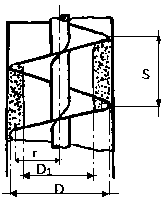

[0017] Embodiment 1 of the present invention: the principle of the present invention is: based on the single-particle motion algorithm, analyze the force situation of the soft coal seam in the auger rod advancing process, thereby deduce the factors that affect the auger rod rotating speed; The calculation and analysis of the coal particle mass delivery rate of the auger drill pipe during drilling, the structural parameters affecting the delivery rate have been obtained, and the optimal structural parameters of the auger drill pipe have been reached.

[0018] 1. Single particle motion analysis

[0019] The coal particles are cut to the drill pipe through the drill bit, and the coal seam is transported out by the centrifugal force of the rotating auger pipe and the friction between the coal particles and the blades. When the speed of the auger pipe is small, the coal seam particles and the helical blades rotate together and The coal seam moves toward the hole wall, but the coal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com