A Method for Evaluating Drill String Fatigue Failure Risk

A technology of fatigue failure and evaluation method, applied in drill pipe, drill pipe, drilling equipment, etc., can solve the hidden danger of safety production, can not fully reflect the stress state of the drill string, and can not better evaluate the risk of fatigue failure of the drill string. , to achieve the effect of reducing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

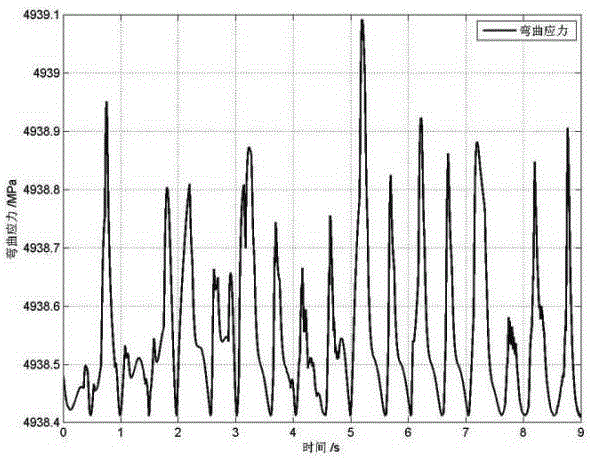

[0051] In this embodiment, the method of the present invention is described in detail by simulating and analyzing the dynamic characteristics of the drill string when drilling to 3168m in the fourth opening of Well X6, which has 18 penetrations in XX oilfield.

[0052] A method for evaluating the risk of fatigue failure of a drill string, which specifically includes the following steps:

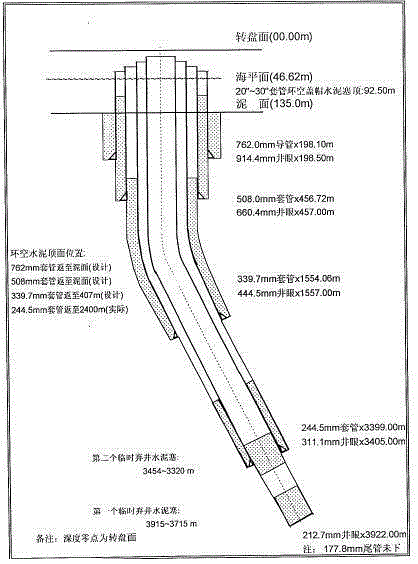

[0053] (1) By obtaining the wellbore trajectory ( Figure 5 ), well structure ( figure 1 ) and the structural parameters of the drill tool assembly as well as its geometric parameters for meshing.

[0054] Drill tool assembly structure:

[0055]

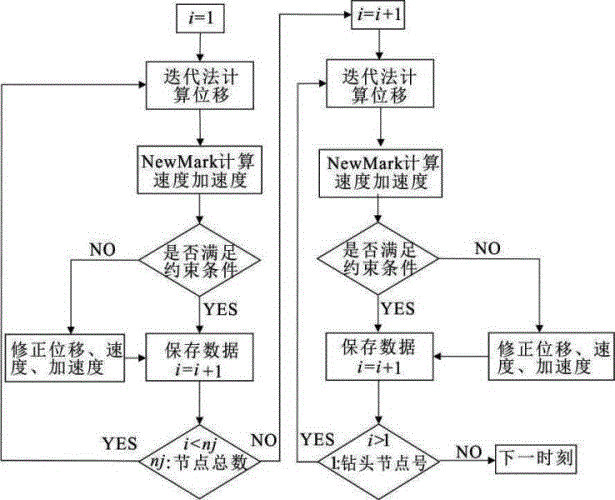

[0056] (2) Solve the element stiffness matrix, element damping matrix, element mass matrix and element node external force vector according to the geometric parameters of the divided elements; integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com