Steel ladder shock-absorbing and sound-reducing structure

A sound reduction and steel ladder technology, which is applied in the direction of stairs, ladders, building structures, etc., can solve the problems of easy bending and deformation of steel ladder pedals, loud noise, etc., and achieve the effect of good appearance and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

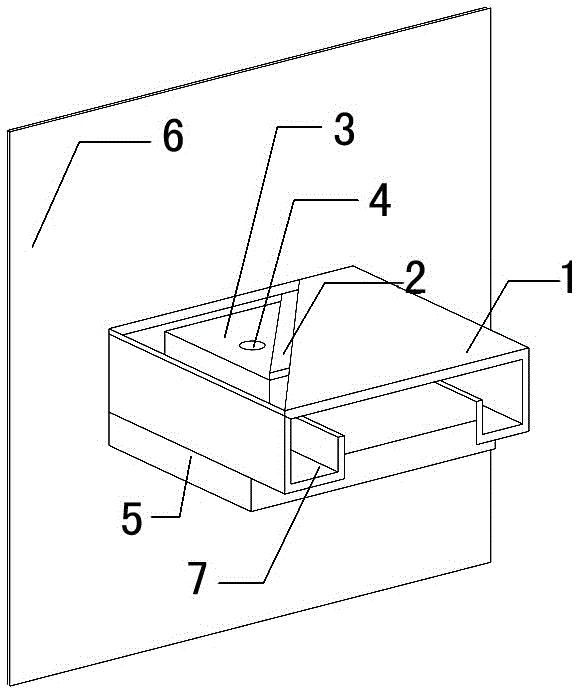

[0018] Example: such as figure 1 As shown, a steel ladder shock-absorbing and sound-reducing structure includes a steel plate step 1, a rubber pad 2, a supporting steel plate 5, and a side plate 6. The steel plate step 1 is treated with antirust. Support steel plate 5 is done antirust treatment, and timber side 3 is done fireproof waterproof anticorrosion treatment. The steel plate step 1 is a step similar to a "П" shape, and the two ends of the bottom of the step are provided with back-shaped grooves 7 for installing light strips.

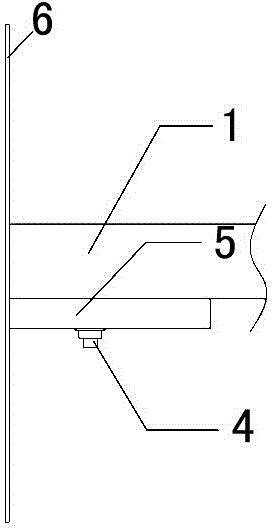

[0019] like figure 2 As shown, first, the supporting steel plate 5 is fixed to the side plate 6 of the staircase.

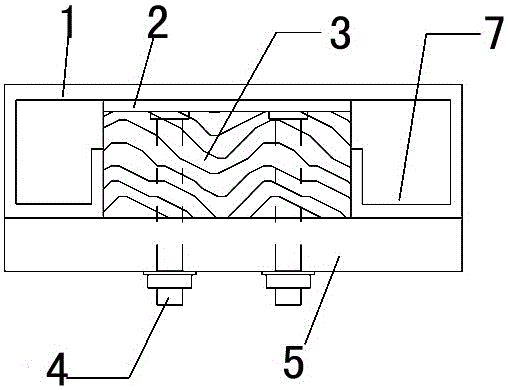

[0020] like image 3 As shown, the wooden side 3 is fixed on the supporting steel plate 5 by the fixing bolt 4, and the rubber pad 2 is placed on the wooden side 3. After the above steps are completed, the steel plate step 1 is installed closely on the shock-absorbing and sound-reducing rubber pad 2, and the two ends of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com