Structural system for controlling transverse response of cable-stayed bridge main beam, auxiliary pier and transition pier

A technology for auxiliary piers and transition piers, applied in the direction of cable-stayed bridges, bridges, bridge parts, etc., can solve the problems of restricting relative movement, safety hazards of main girders, auxiliary piers and transition piers, large lateral displacement and internal force response of cable-stayed bridges, etc. problems, achieve the effects of reducing construction costs, ensuring structural safety and functional requirements, and optimizing lateral structural stiffness and structural damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

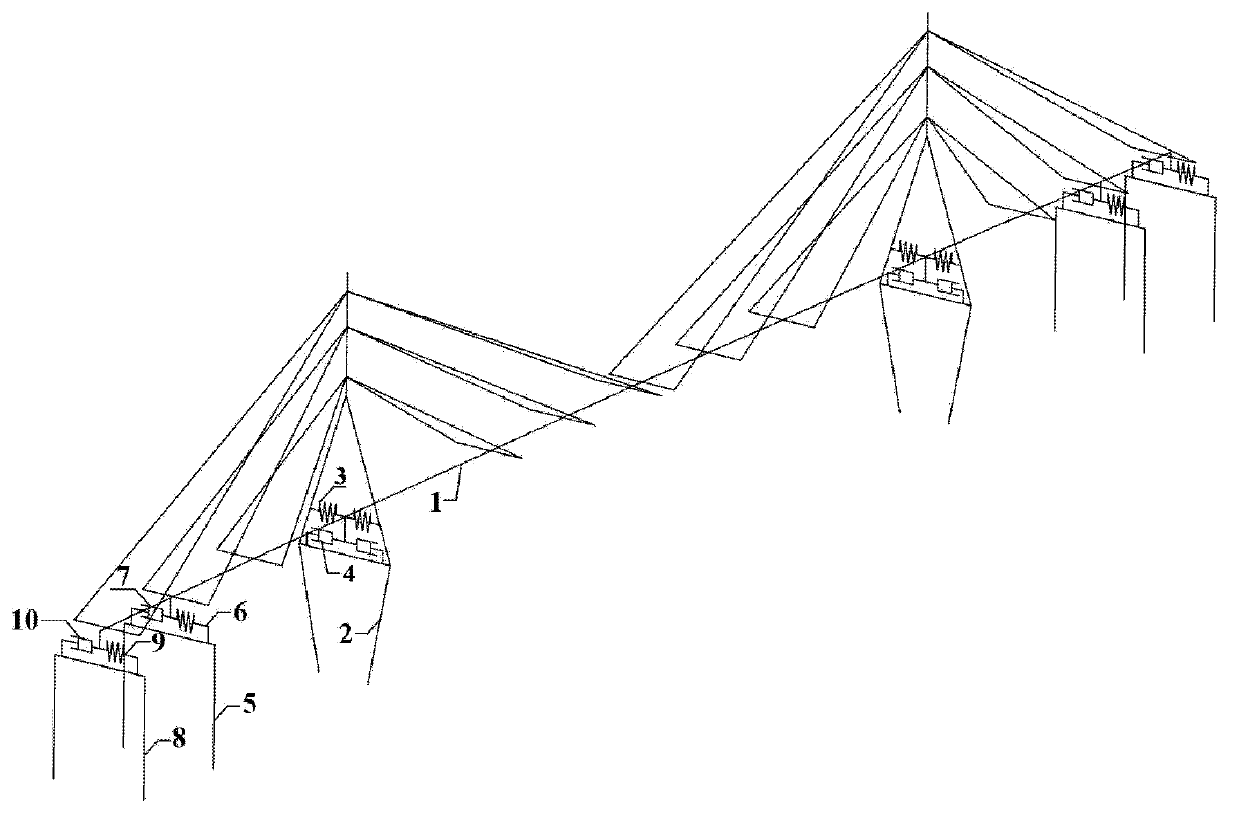

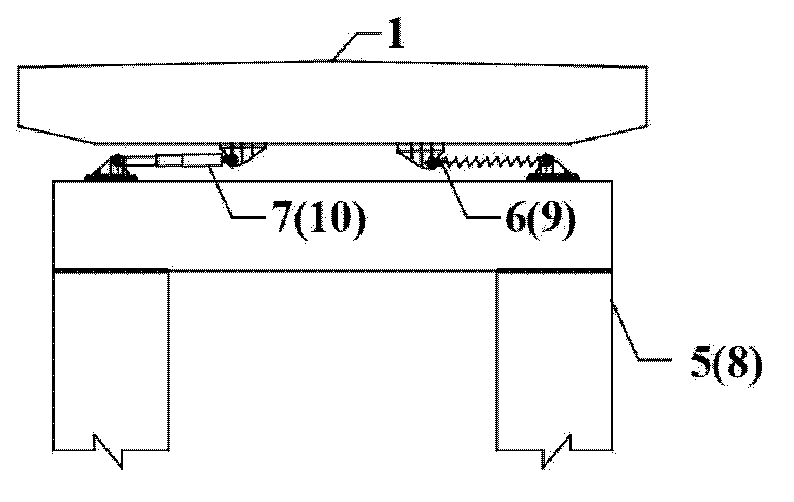

[0028] Such as figure 1 as shown, figure 1 It is a schematic diagram of the structural system for controlling the lateral response of the cable-stayed bridge girder, auxiliary pier and transition pier provided by the present invention. figure 1 The shown cable-stayed bridge has a main girder 1, a bridge tower 2, an auxiliary pier 5 and a transition pier 8, and the structural system for controlling the lateral response of the cable-stayed bridge main girder, auxiliary pier and transition pier includes:

[0029] A plurality of first elastic supports 3 and a plurality of first dynamic damping devices 4 arranged laterally between the main girder 1 and the bridge tower 2; a plurality of second elastic supports 6 arranged laterally between the main girder 1 and the auxiliary pier 5 and a plurality of second dynamic damping devices 7 ; and a plurality of third elastic supports 9 and a plurality of third dynamic damping devices 10 arranged transversely between the main beam 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com