Composite surfactant and preparation method thereof

A composite surfactant and surfactant technology, applied in the field of composite surfactant and its preparation, can solve the problems of poor temperature resistance and salt resistance, increased oil-water interfacial tension, low interfacial activity, etc., and achieve excellent temperature resistance, The effect of increasing surface activity and increasing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

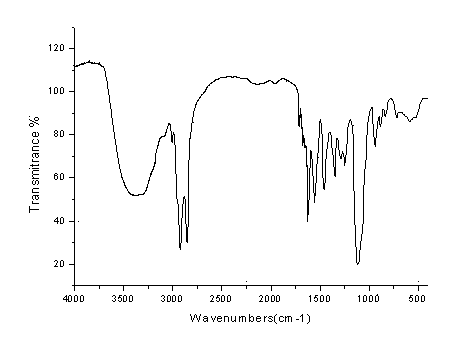

Image

Examples

Embodiment 1

[0050] (a) Synthesis of octadecyl polyoxypropylene (m=3) polyoxyethylene (n=10) ether

[0051] Add 270 grams (1 mole) of stearyl alcohol, 5 grams of potassium hydroxide and 1.75 grams of anhydrous potassium carbonate to a pressure reactor equipped with a stirring device. Dehydrate under vacuum for 2 hours, then replace with nitrogen for 3 to 4 times, adjust the reaction temperature of the system to 150°C and slowly introduce 176.9 grams (3.05 moles) of propylene oxide, control the pressure ≤ 0.40MPa, after the reaction of propylene oxide is completed , lower the temperature, and slowly feed 444.4 grams (10.1 moles) of ethylene oxide at 140° C. to control the pressure to ≤0.60 MPa. After the reaction, lower the temperature to 90°C, remove low boilers in vacuum, neutralize and dehydrate after cooling to obtain 869.9 grams of stearyl alcohol polyoxypropylene (m=3) polyoxyethylene (n=10) ether, with a yield of 98.4% .

[0052] (b) Synthesis of octadecyl polyoxypropylene (m=3) po...

Embodiment 2

[0057] (a) Synthesis of nonylphenol polyoxypropylene (m=8) polyoxyethylene (n=6) ether

[0058]Add 220 grams (1 mole) of nonylphenol, 4 grams of potassium hydroxide and 2.6 grams of anhydrous potassium carbonate to a pressure reactor equipped with a stirring device, and when heated to a reaction temperature of 80-90°C, open the vacuum system and Dehydrate under vacuum for 1 hour, then replace with nitrogen for 3 to 4 times, adjust the reaction temperature of the system to 150°C and slowly introduce 469.8 grams (8.1 moles) of propylene oxide, control the pressure ≤ 0.50MPa, after the reaction of propylene oxide is completed , lower the temperature, and slowly feed 266.2 grams (6.05 moles) of ethylene oxide at 130° C., and control the pressure to ≤0.60 MPa. After the reaction, the same post-treatment as in [Example 1] was performed to obtain 921.5 g of nonylphenol polyoxypropylene (m=8) polyoxyethylene (n=6) ether, with a yield of 97.2%.

[0059] (b) Synthesis of potassium nony...

Embodiment 3

[0063] (a) Synthesis of behenylpolyoxypropylene (m=4) polyoxyethylene (n=2) ether

[0064] Add 326 grams (1 mole) of behenyl alcohol, 5 grams of potassium hydroxide and 5.5 grams of anhydrous potassium carbonate into the pressure reactor equipped with a stirring device, and when the reaction temperature is 80-90 ° C, open the vacuum system and Dehydrate under high vacuum for 2 hours, then replace with nitrogen for 3 to 4 times, adjust the reaction temperature of the system to 160°C and slowly introduce 234.9 grams (4.05 moles) of propylene oxide, control the pressure ≤ 0.60MPa, and wait until the reaction of propylene oxide is completed After that, the temperature was lowered, and 90.2 g (2.05 moles) of ethylene oxide was slowly introduced at 140° C., and the pressure was controlled to be ≤0.60 MPa. After the reaction, the same post-treatment as in [Example 1] obtained 619.5 g of behenyl polyoxypropylene (m=4) polyoxyethylene (n=2) ether, with a yield of 95.9%.

[0065] (b) S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com