Carbon black particle dispersing agent, preparation method and application thereof

A dispersant and particle technology, applied in the field of dispersant and its preparation, can solve the problems of carbon black agglomerate dispersion, etc., and achieve the effect of improving various properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation of carbon black particle dispersant of the present invention and the method for dispersing carbon black particle thereof:

[0030] 1) Configure mixed solution: mix sodium taurocholate or sodium dodecylbenzenesulfonate and sodium taurocholate with ethylene glycol at a mass ratio of 1:1, and then mix with ethanol at a mass ratio of 1:9 Mix to obtain the carbon black particle dispersant;

[0031] 2) Add carbon black powder: add 1g carbon black powder to 50ml mixed solution;

[0032] 3) Ultrasonic oscillation: put the mixture obtained in step 2) into an ultrasonic oscillator for oscillation, the temperature of the ultrasonic oscillation is controlled as an ice bath, and the oscillation time is 4 hours;

[0033] 4) Sample preparation: drop the solution of step 3) on the carbon support membrane with a pipette. Put the prepared carbon support membrane into a desiccator, and it can be detected after 24 hours;

[0034] 5) Image acquisition: use a transmission ...

Embodiment 1

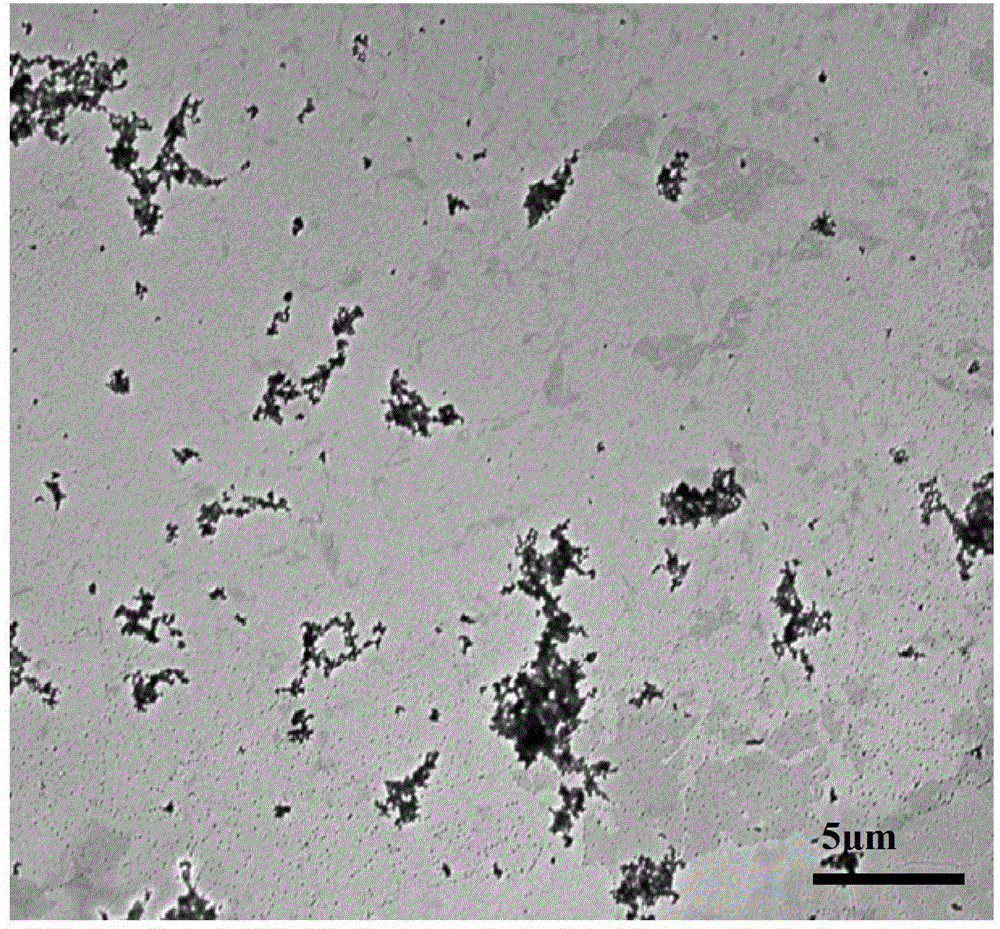

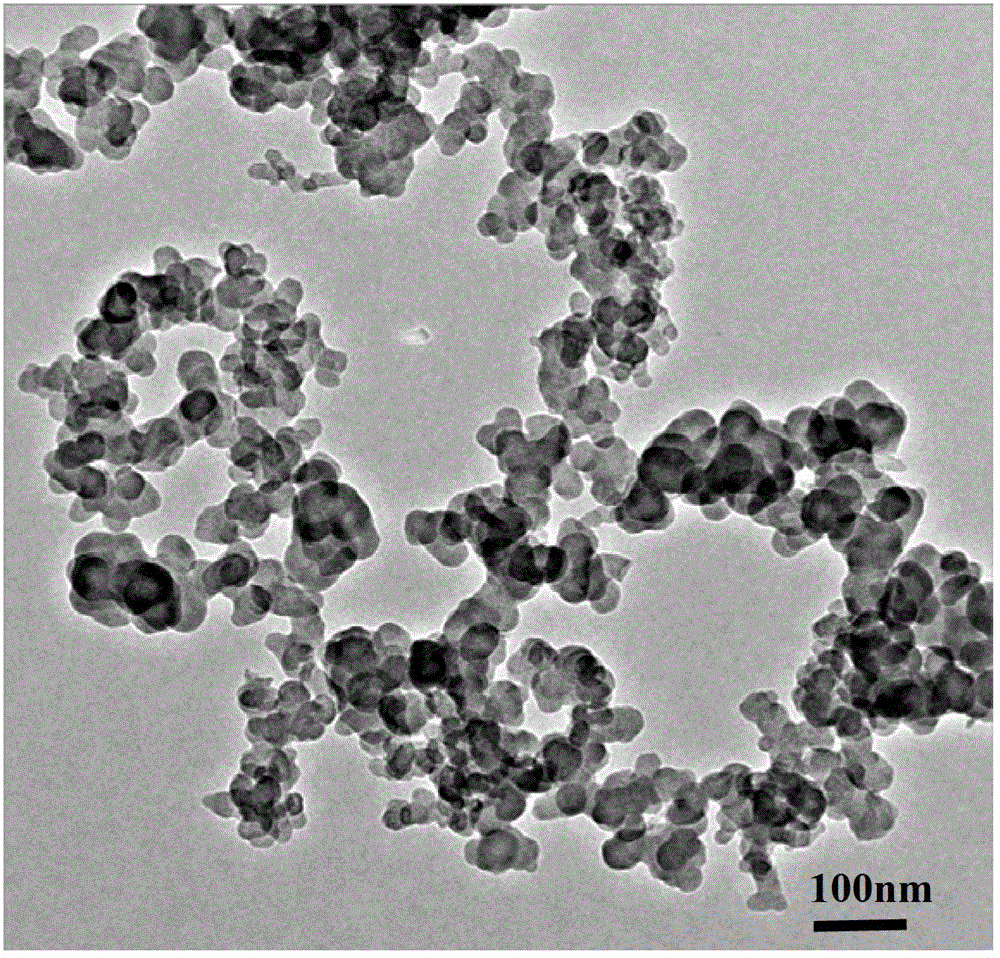

[0036] 5 parts by mass of sodium dodecylbenzenesulfonate, 5 parts by mass of ethylene glycol, and 90 parts by mass of ethanol were mixed to obtain the carbon black particle dispersant 1 of the present invention. The electron micrograph of the carbon black particle dispersed through the present embodiment formula is as follows figure 1 and figure 2 shown.

Embodiment 2

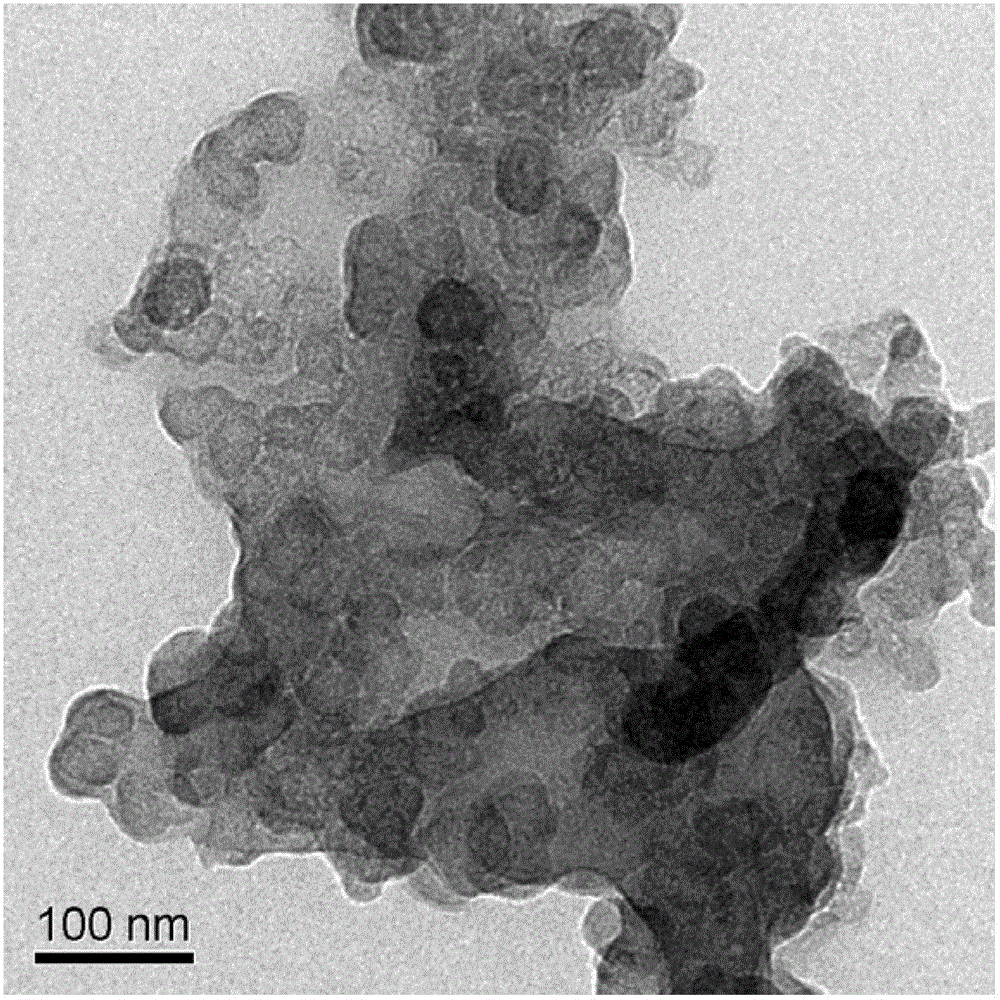

[0038] 5 parts by mass of sodium taurocholate, 5 parts by mass of ethylene glycol, and 90 parts by mass of ethanol were mixed to obtain the carbon black particle dispersant 2 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com