System for continuously separating and purifying amino acid from water solution of amino acid containing alkaline metal salt

An alkali metal salt, separation and purification technology, applied in the direction of purification/separation/stabilization of organic compounds, organic chemistry, organic chemical methods, etc., can solve the problem of affecting the quality of amino acid products, peritectic phenomenon, and iminodicarboxylic acid imino acid Solve problems such as separation, achieve the effect of easy operation, avoid peritectic, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

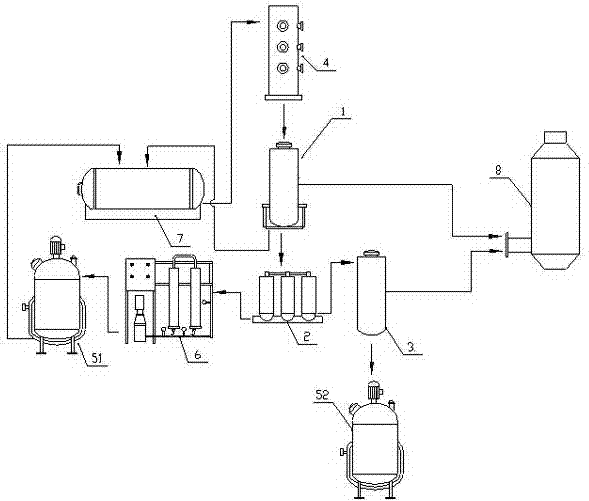

Image

Examples

Embodiment 1

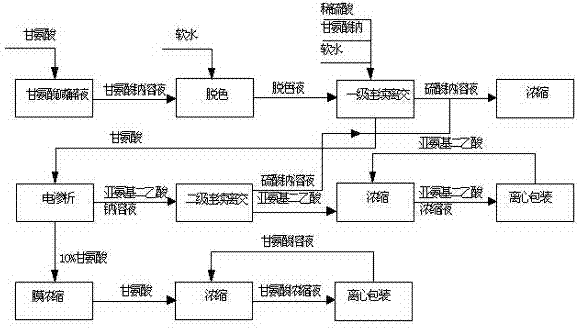

[0036] Taking the continuous separation and purification of glycine from the aqueous solution of sodium glycinate as an example, the preferred embodiment scheme of the system of the present invention is described according to the first embodiment. For the schematic flow chart of the continuous separation and purification of glycine from the aqueous solution of sodium glycinate, see image 3 shown.

[0037] Sodium glycinate solution contains a lot of colored impurities, the color is dark brown, and its composition is as follows: about 12% sodium glycinate, about 2% sodium iminodiacetic acid, about 1% sodium hydroxide, about 0.2% sodium nitrilotriacetate and a small amount of NH 3 .

[0038] The above-mentioned sodium glycinate solution first uses 10% glycine solution to adjust the pH of the raw material to about 10-12, and then enters the decolorization tower 4 for decolorization treatment, and obtains a sodium glycinate clear liquid after decolorization. The sodium glycinate...

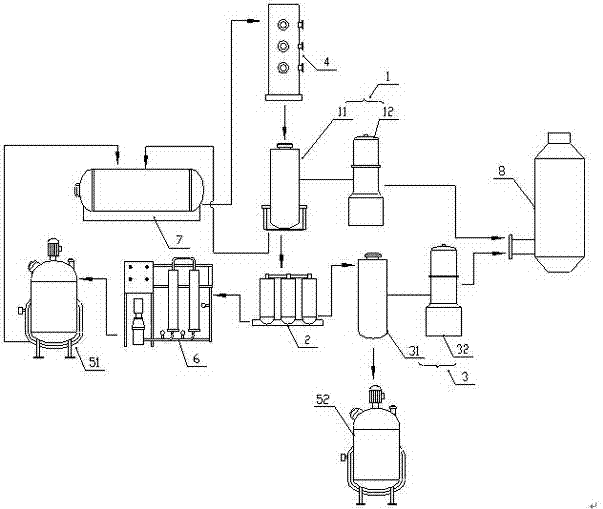

Embodiment 2

[0043] Taking the continuous separation and purification of glycine from the aqueous solution of sodium glycinate as an example, the preferred embodiment scheme of the system of the present invention is described according to the second embodiment. The schematic flow chart of the continuous separation and purification of glycine from the aqueous solution of sodium glycinate can be found in image 3 shown.

[0044] Sodium glycinate solution contains a lot of colored impurities, the color is dark brown, and its composition is as follows: about 12% sodium glycinate, about 2% sodium iminodiacetic acid, about 1% sodium hydroxide, about 0.2% sodium nitrilotriacetate and a small amount of NH 3 .

[0045] The above-mentioned sodium glycinate solution first uses 10% glycine solution to adjust the pH of the raw material to about 10-12, and then enters the decolorization tower 4 for decolorization treatment, and obtains a sodium glycinate clear liquid after decolorization. The sodium g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com