Dumper frame

A dump truck and frame technology, which is applied in the field of mining dump truck frames, can solve the problems of insufficient overall structural strength, low structural strength, and large vehicle body volume, and achieve compact structure, reasonable layout design, and good strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings of the description.

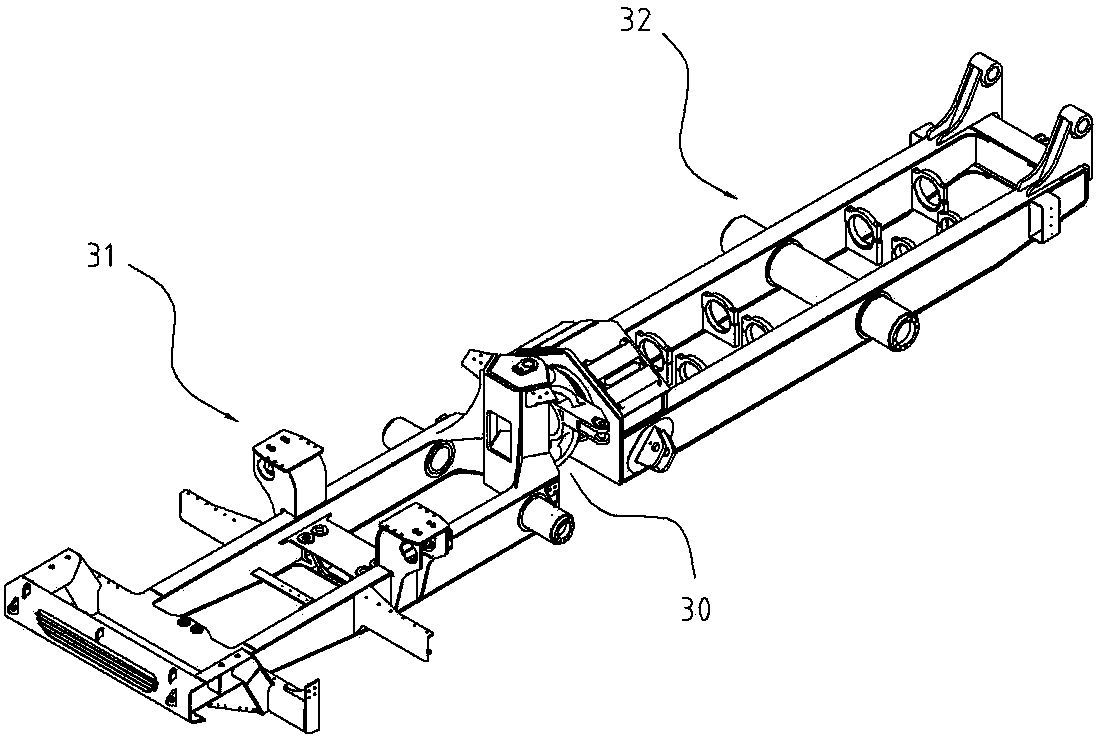

[0026] figure 1 As shown, a dump truck frame includes a front frame 31 , a rear frame 32 and a hinge assembly 30 connecting the front frame 31 and the rear frame 32 .

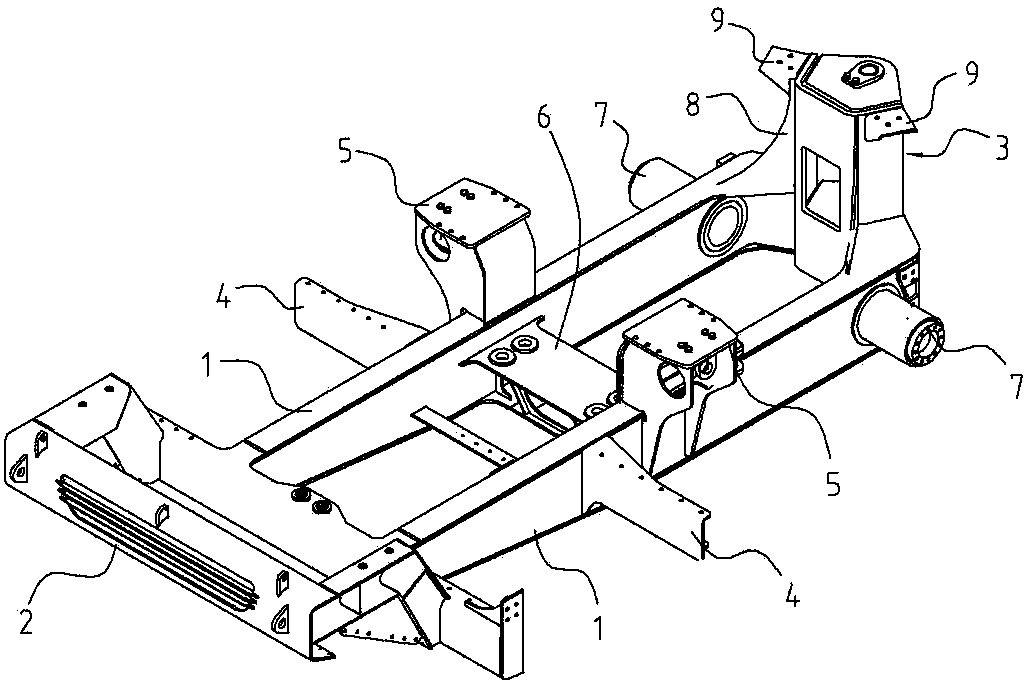

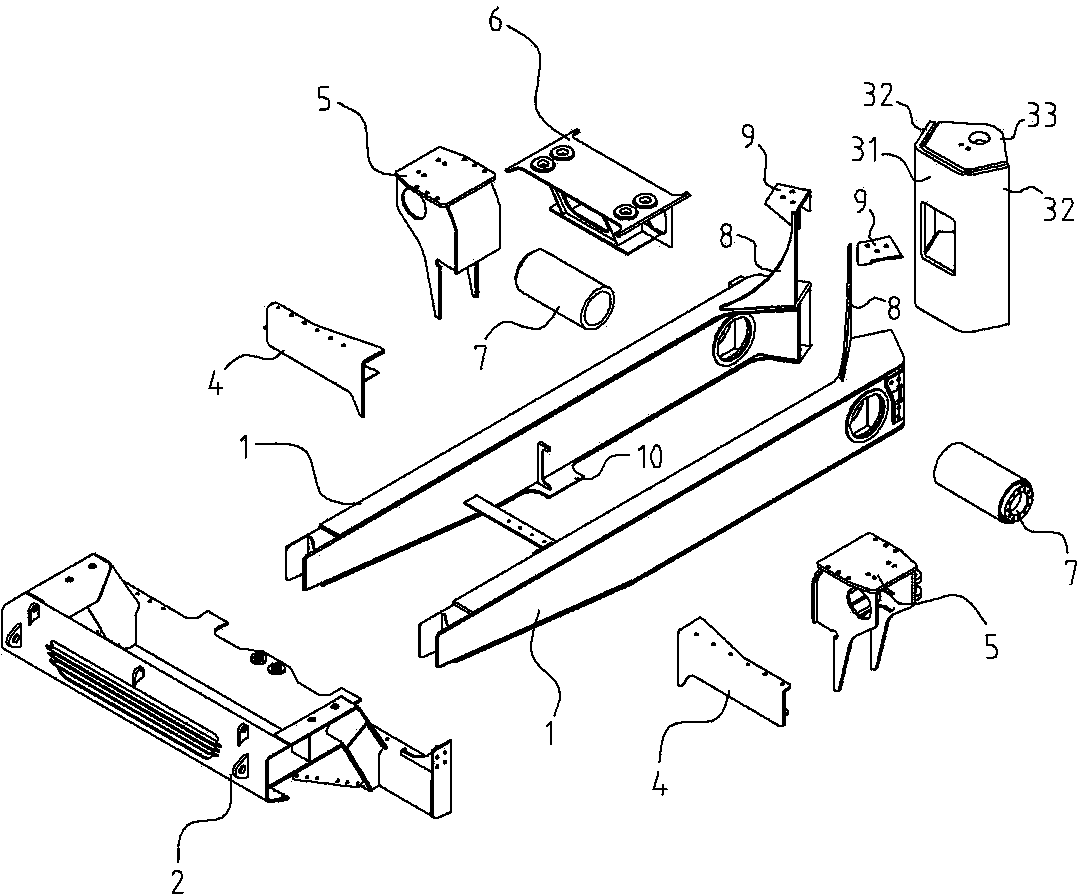

[0027] like figure 2 , 3 As shown, the front frame of the vehicle includes two symmetrical front frame beam assemblies. The rear ends of the two front frame beam assemblies are provided with hinged seats 3 , and the front ends are provided with frame front assemblies 2 . The front frame beam assembly includes a front frame longitudinal beam 1 in a box-shaped structure, a front frame beam 4 arranged on the middle outer surface of the front frame longitudinal beam 1, a front frame beam 4 arranged on the front frame longitudinal beam 1 in the middle of the front cantilever bracket 5, the front frame anti-torsion tube 7 arranged on the outer side of the rear end of the front frame lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com