Automatic copper nail hot-melt assembly inspection machine based on industrial manipulator

An industrial manipulator and fully automatic technology, which is applied in the field of fully automatic copper nail hot-melt assembly inspection machine, can solve the problems of low degree of automation, error-prone, and high labor intensity of operators, and achieve the effect of reducing labor intensity and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

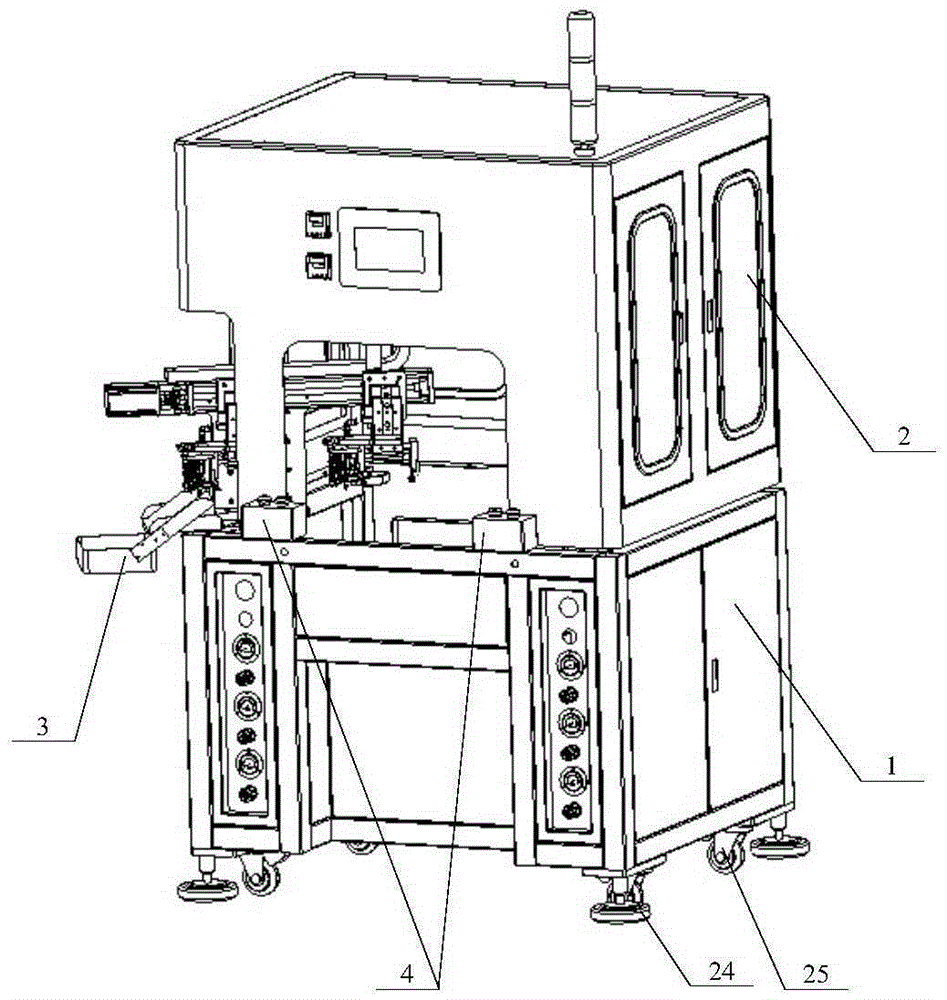

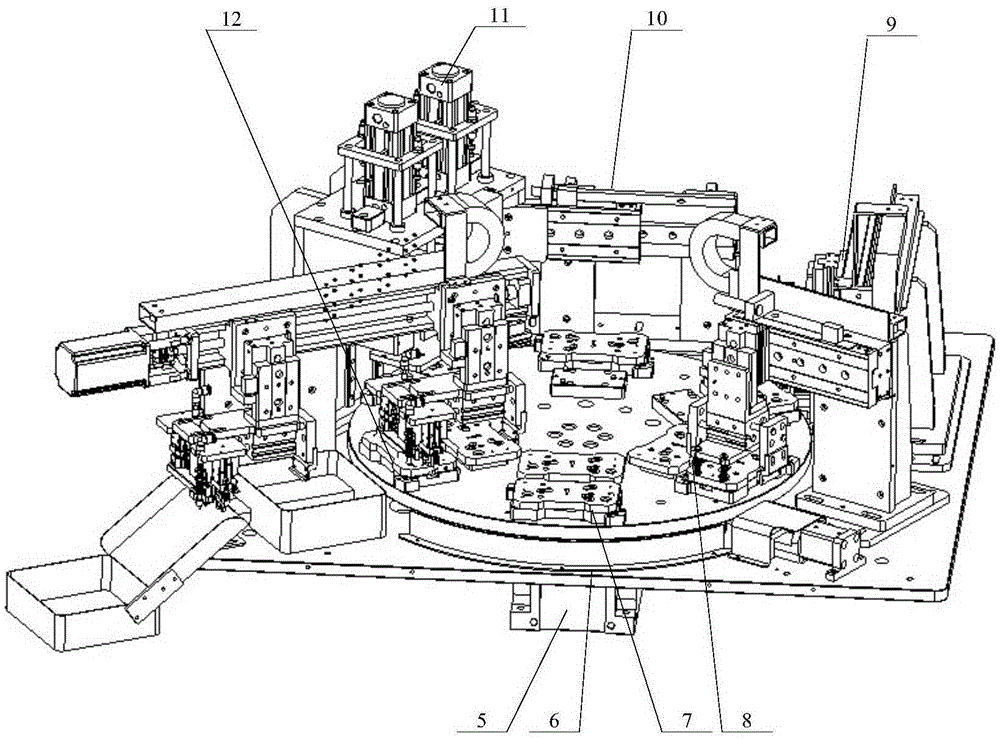

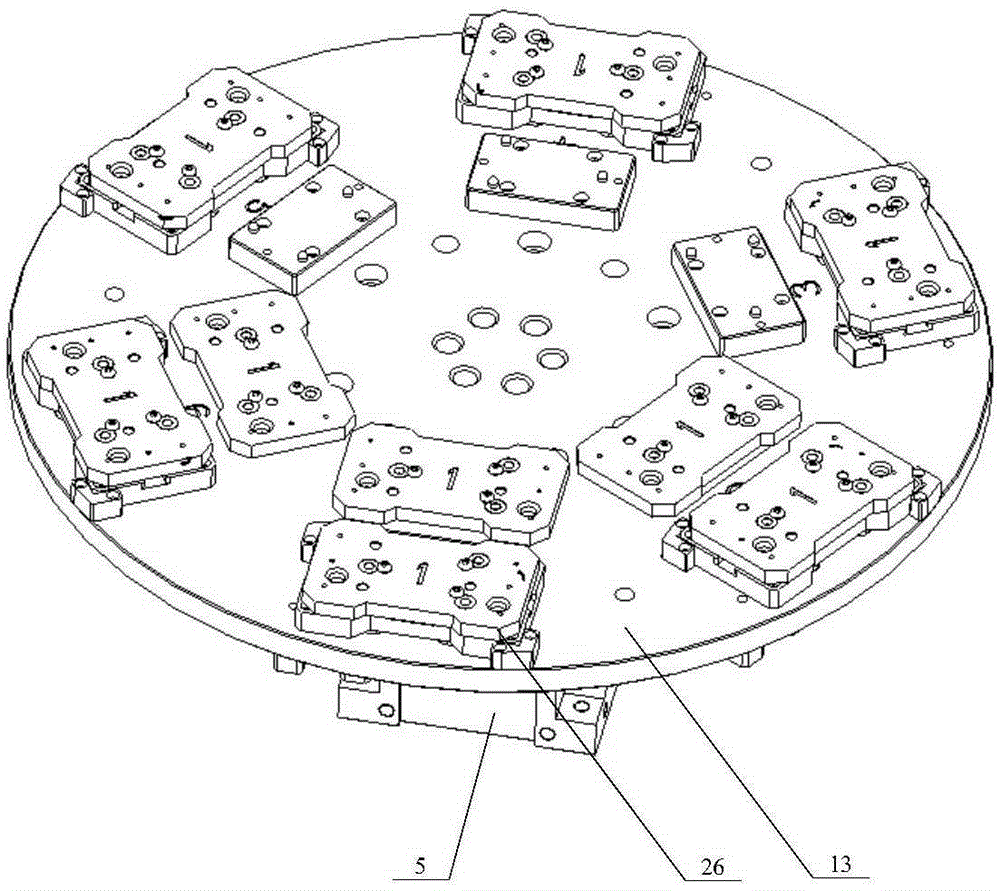

[0025] Figure 1 to Figure 8 A specific embodiment of this automatic hot-melt copper nail assembly machine based on industrial manipulators of the present invention is shown, its external dimensions are 1650mmx1400mmx1900mm, including a frame 1, a six-station divider 6 ( The so-called "six-station divider" refers to that it rotates once, the angle of rotation is 360° / 6=60°), the rotating disk 13 that is fixedly connected to the six-station divider, and the driving of the six-station The divider 6 is rotated by the servo motor 5 in the frame 1 . The turntable 13 is provided with six product positioning jigs 26 evenly distributed along the circumferential direction, and the frame 1 is also provided with product placement fixtures located around the turntable 13 and uniformly distributed sequentially along the circumferential direction of the turntable 13. Station 7, product cover plate placing station 8, first copper nail picking and placing station 9, second copper nail pickin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com