Two-way crawling light mobile parallel normal drilling device

A hole-making device and mobile technology, which is applied in the field of two-way crawling light-duty mobile parallel-connected normal hole-making devices, can solve the problems of inconvenient line-changing processing, many driving motors, and low processing efficiency, and achieve compact structure, fewer driving motors, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

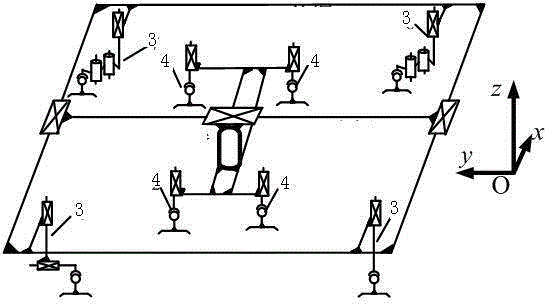

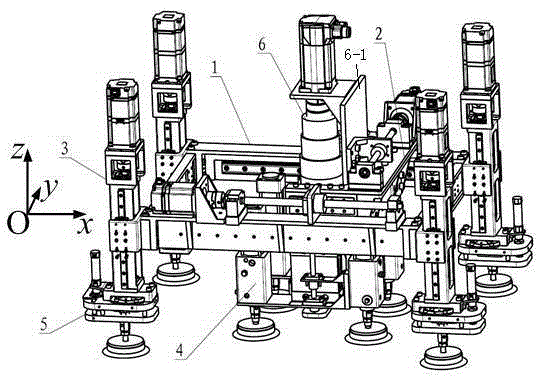

[0027] like Figure 1-10 shown.

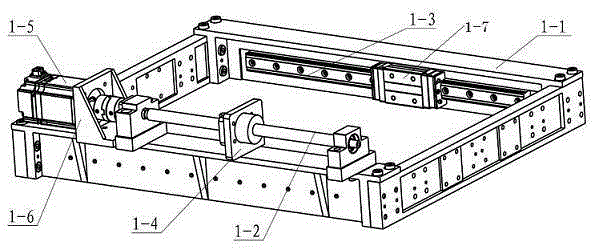

[0028] A two-way crawling light-duty mobile parallel normal hole-making device, which includes an outer frame 1, a terminal actuator fixing frame 2 and an end effector 6, and the four corners of the outer frame 1 are respectively connected with an outer frame driven by a motor. The lifting leg 3 and the end effector 6 are connected with four inner lifting legs 4 driven by cylinders, such as figure 2 As shown; while both sides of the terminal actuator fixing frame 2 are respectively connected with the X-direction slider 1-7 installed on the X-guiding rail 1-3 inside the outer frame 1, the terminal actuator fixing frame 2 One side is also connected with the outer frame connection plate 1-4 suspended on the outer frame 1, the X direction lead screw nut is installed on the outer frame connection plate 1-4, and the X dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com