Crankshaft turning and milling machine tool and its tool turret

A tool turret and crankshaft technology, applied to milling machine equipment, milling machine equipment details, other manufacturing equipment/tools, etc., can solve problems such as troubles, achieve the effects of avoiding deflection, improving mobility, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

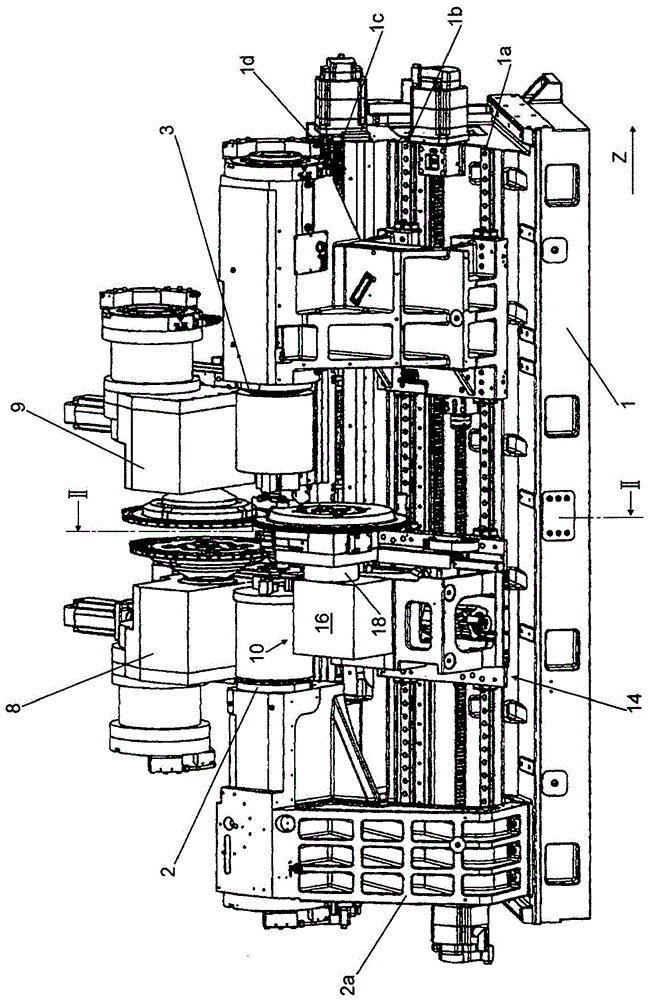

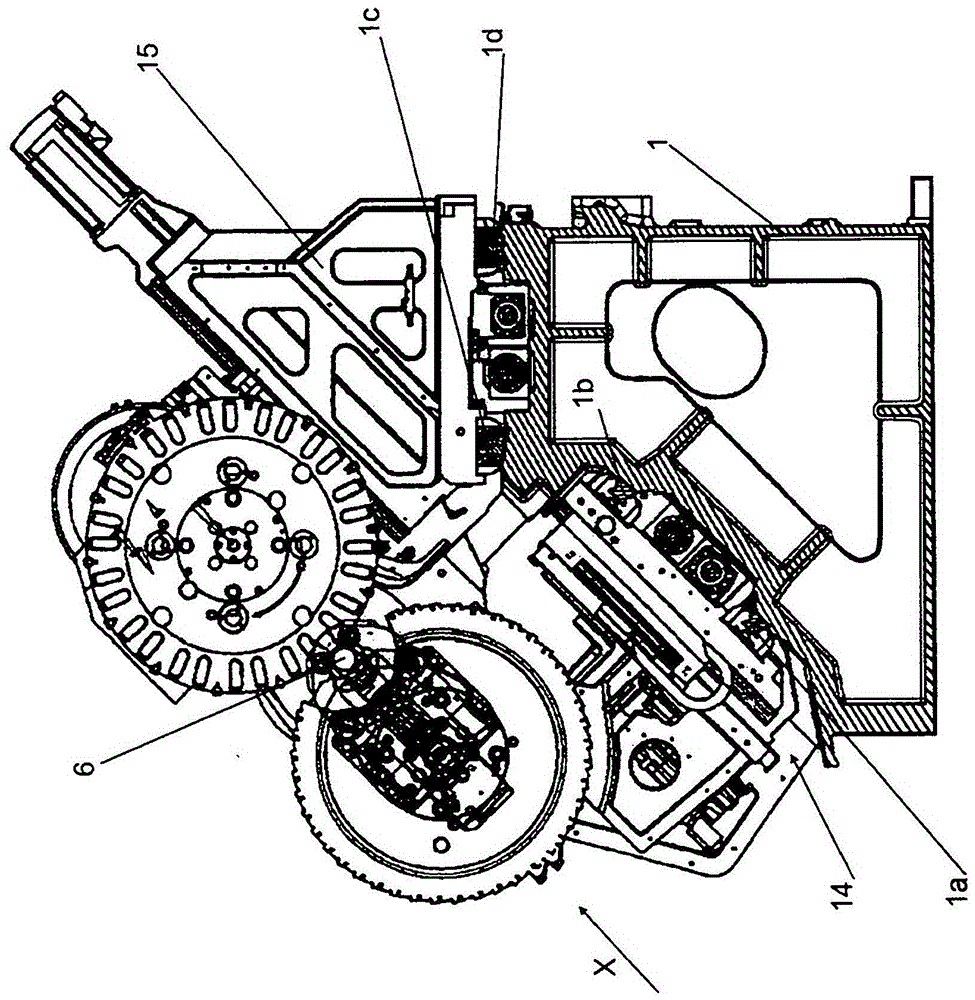

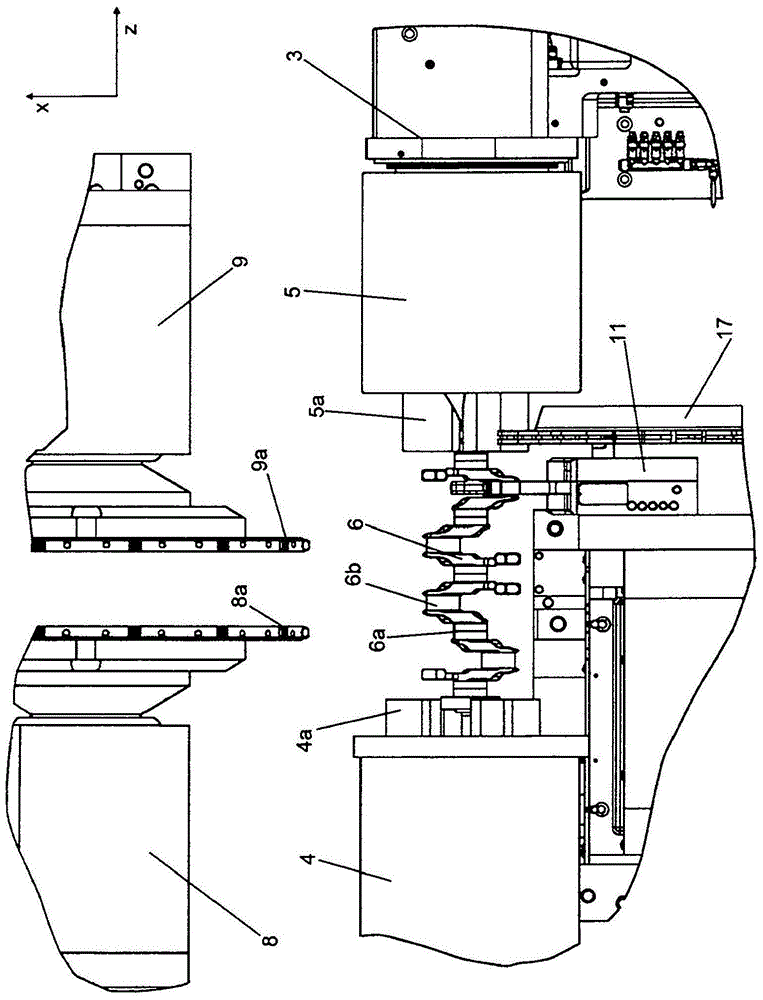

[0023] exist figure 1 The crankshaft turning-milling machine shown in FIG. 1 has a machine tool 1 . The machine tool is provided with lower guides 1a and 1b and upper guides 1c and 1d. On one end of the machine tool 1, a headstock 2a is fixed immovably. The first workpiece spindle 2 is mounted rotatably about its spindle axis in the headstock. The second workpiece spindle 3 is supported displaceably in the direction of the spindle axis on the lower guides 1a, 1b. The two spindle axes are oriented parallel to the direction Z. The workpiece spindle 3 carries an associated chuck 5, and the workpiece spindle 2 carries an associated chuck 4 facing the chuck 5, so that a crankshaft workpiece 6 can be clamped between the chucks 4, 5 (see Figures 2 to 5 ).

[0024] Mounted on the lower guides 1 a , 1 b is an Oldham slide 14 , which is displaceable in the direction Z of the spindle axis and in the direction X transverse to the direction of the spindle axis. The Oldham slide 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com