High-precision positioning automatic screwing system

A screw-driving, high-precision technology, which is applied in the field of automatic screw-driving systems, can solve the problems of increasing manpower input and wasting labor, and achieve the effects of promoting automation, saving labor costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

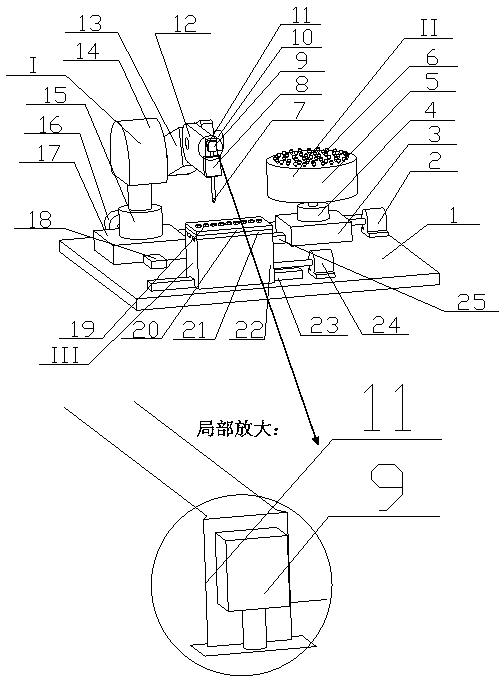

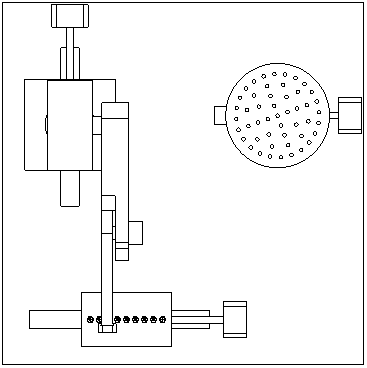

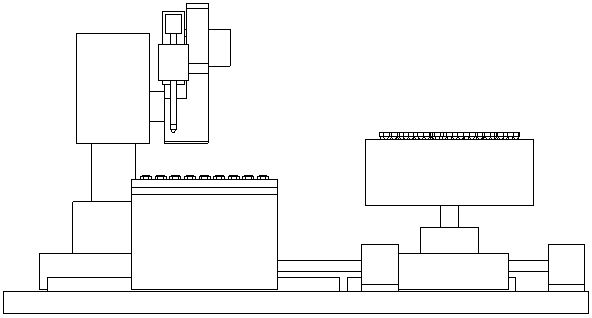

[0020] In this example, see Figure 1 to Figure 6 , the automatic screw screwing system with high precision positioning, including mechanical arm device I, turntable device II, feeding device III, chassis 1, control system and power supply, on chassis 1 there are slide rail A 18, slide rail B 23, slide rail C 25, manipulator device I, turntable device II, feeding device III are all installed on the chassis 1, respectively with slide rail first 18, slide rail second 23, slide rail third 25 slip matching and pneumatically driven to move.

Embodiment 2

[0022] This embodiment is basically the same as Embodiment 1, and the special features are:

[0023] Described mechanical arm device 1 comprises screwdriver head 7, slide block first 8, cylinder first 9, motor first 10, slide rail 11, connecting rod first 12, connecting rod second 13, connecting body 14, motor second 15, cylinder second 16, Sliding base first 17 and slide rail first 18; Described sliding base first 17 and described slide rail first 18 sliding match; Described cylinder second 16 is fixed on the described chassis 1, and the piston rod one end of described cylinder second 16 is connected with the The sliding base A 17 is fixedly connected; the motor B 15 is fixed on the sliding base A 17, the connecting body 14 is rotationally connected with the output shaft of the motor 15, and the connecting body 14 has a built-in motor; Rod B 13 is rotationally connected with the motor output shaft built into the connecting body 14; the connecting rod A 12 rotates with the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com