Modified structure of laser marking machine and method for machining hollowed-out matrix through laser marking machine

A laser marking machine and typeface technology, which is applied in the field of laser marking machines, can solve the problems of thick laser beam diameter, use of hollowing equipment, substandard fonts, etc., and achieve the goals of reducing beam diameter, increasing the speed of technicians, and increasing laser power density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

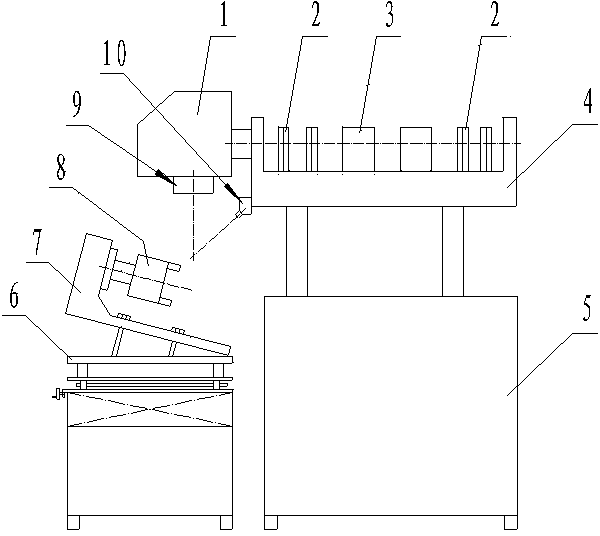

[0016] like figure 1 As shown: the laser marking machine provided by the present invention consists of a bracket 4 fixed on the cabinet 5, a fiber laser 3 fixed on the bracket, a plurality of two-dimensional lens adjustment frames 2 fixed on the bracket, and a plurality of two-dimensional lens adjustment frames 2 fixed on the bracket. The red light indicator 10 on the top and the high-speed scanning galvanometer 1, the lens 9 fixed on the high-speed scanning galvanometer, and the rotary chuck 8 fixed on the three-dimensional worktable 6 through the inclined working plate 7 are composed.

[0017] The specific method of utilizing the laser marking machine of the present invention to process hollow fonts is as follows:

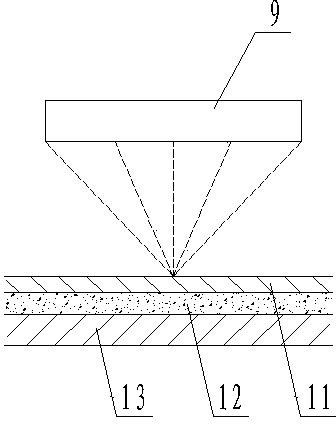

[0018] 1) Fix the font 11 (that is, the workpiece) on the inclined working plate 7 through the clamp (not shown in the figure) or the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com