Handheld type self-puncture riveting machine

A self-piercing and riveting machine technology, which is applied in the field of riveting equipment, can solve the problems of bulky riveting equipment, long processing time for several punches, and difficulty in using handheld devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

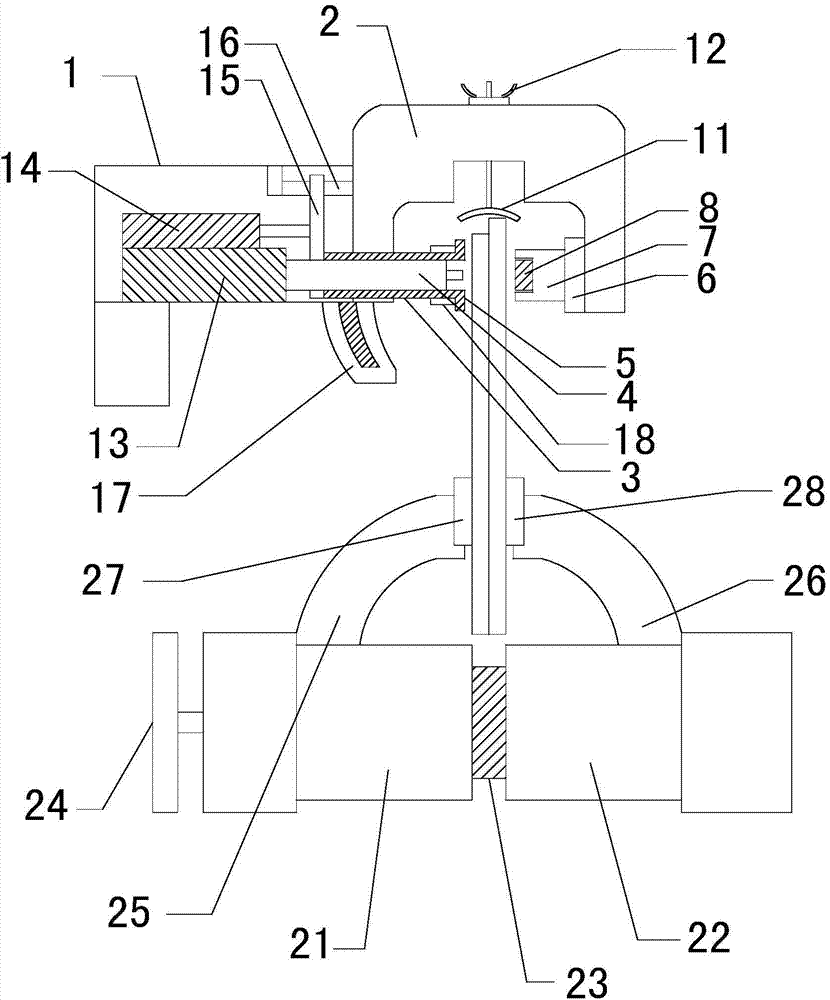

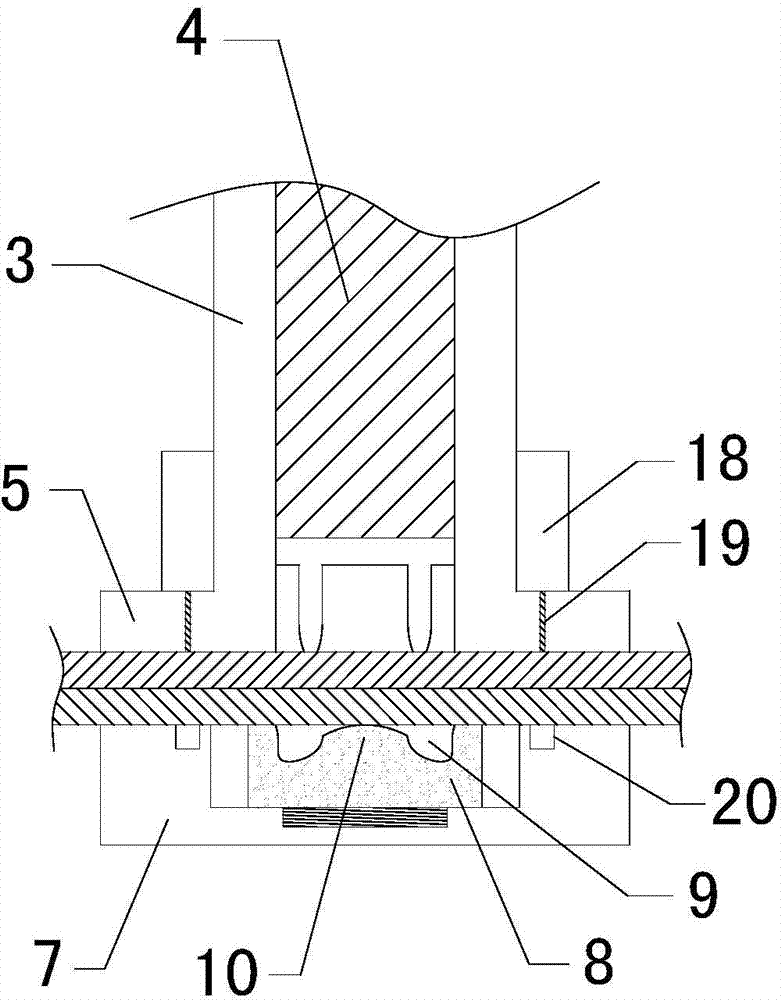

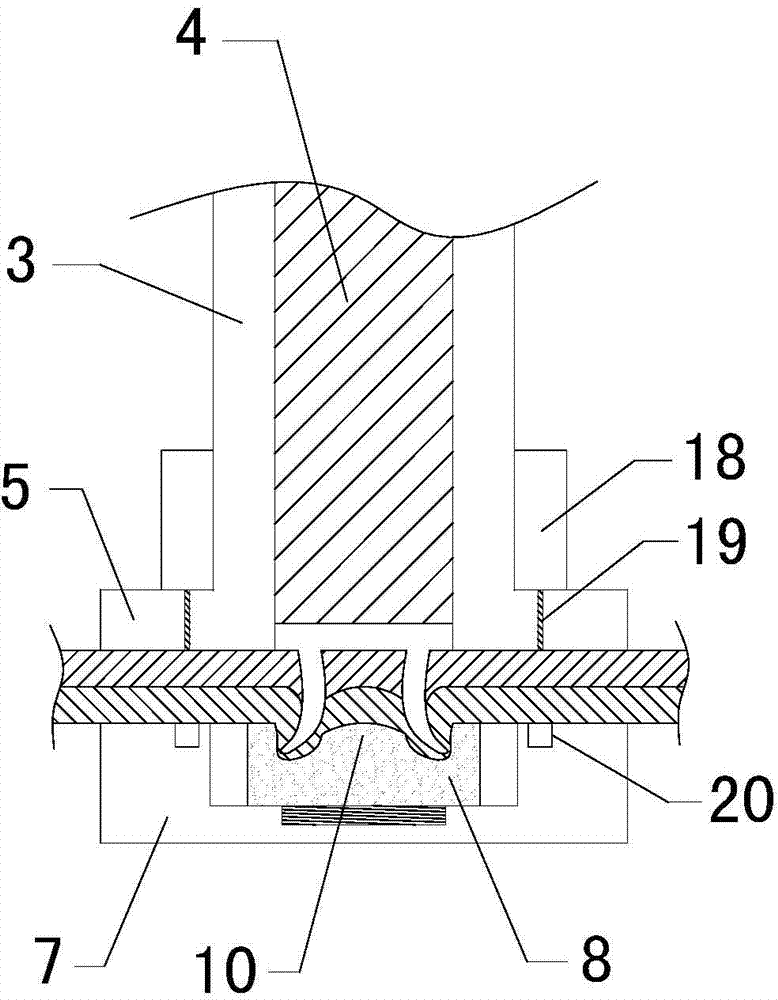

[0018] see Figure 1 to Figure 3 As shown, a hand-held self-piercing riveting machine includes a hand-held riveting body 1 and a clamping body 2 arranged at the front end of the hand-held riveting body 1. The hand-held riveting body 1 is provided with a sleeve mold 3 that slides relatively and has a hollow structure, and The upper mold 4 which is arranged in the sleeve mold 3 and slides relative to the sleeve mold, the front end of the sleeve mold 3 is provided with a ring-shaped and integrated pressure plate 5, and the clamping body 2 is located at a position opposite to the sleeve mold 3. The sliding seat 6 that can slide relatively, the sliding seat 6 is fixed on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com