Production process of air-conditioner fin

A production process and technology of air-conditioning fins, applied in the field of air-conditioning fins, can solve problems such as difficult feeding, low production efficiency, and unstable operation, and achieve the effects of solving difficult feeding, high production efficiency, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

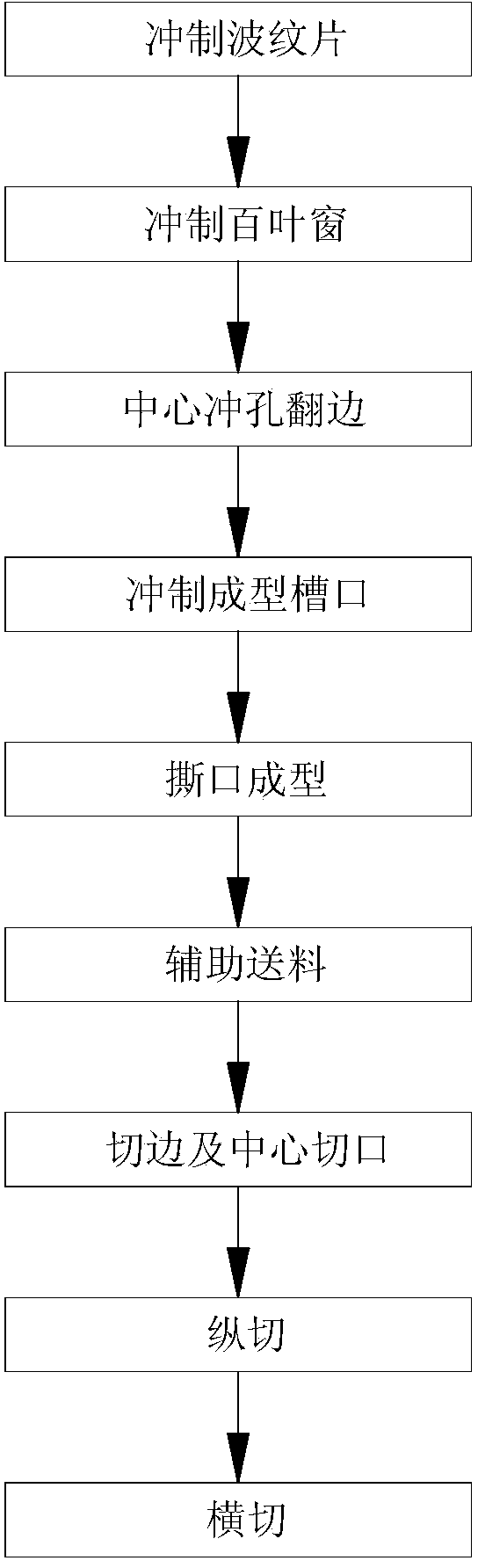

Method used

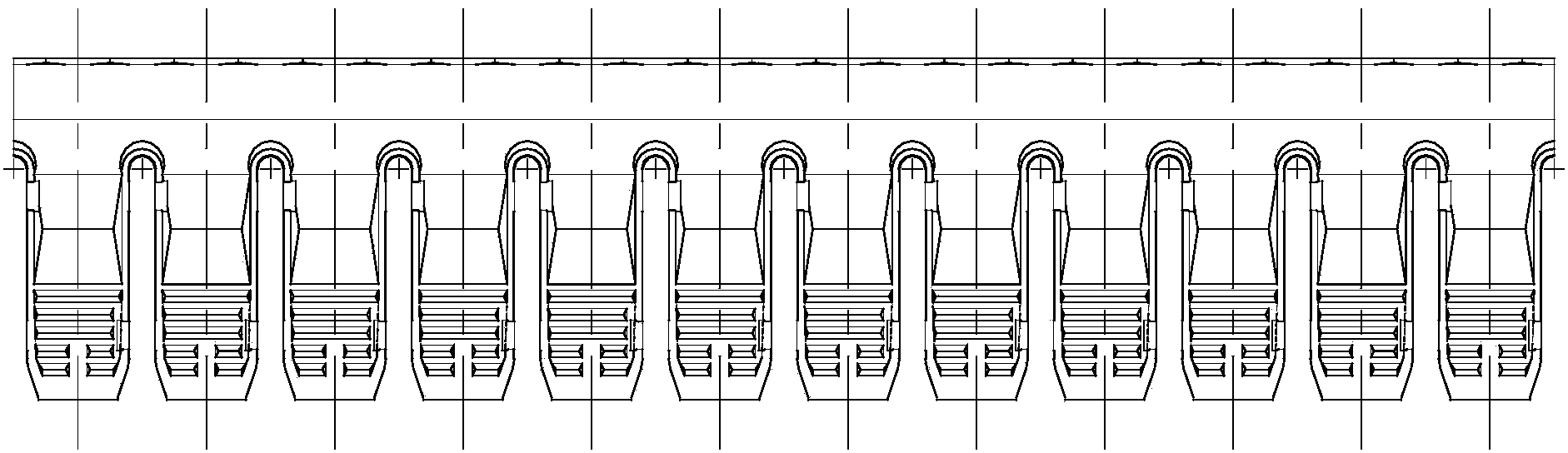

Image

Examples

Embodiment Construction

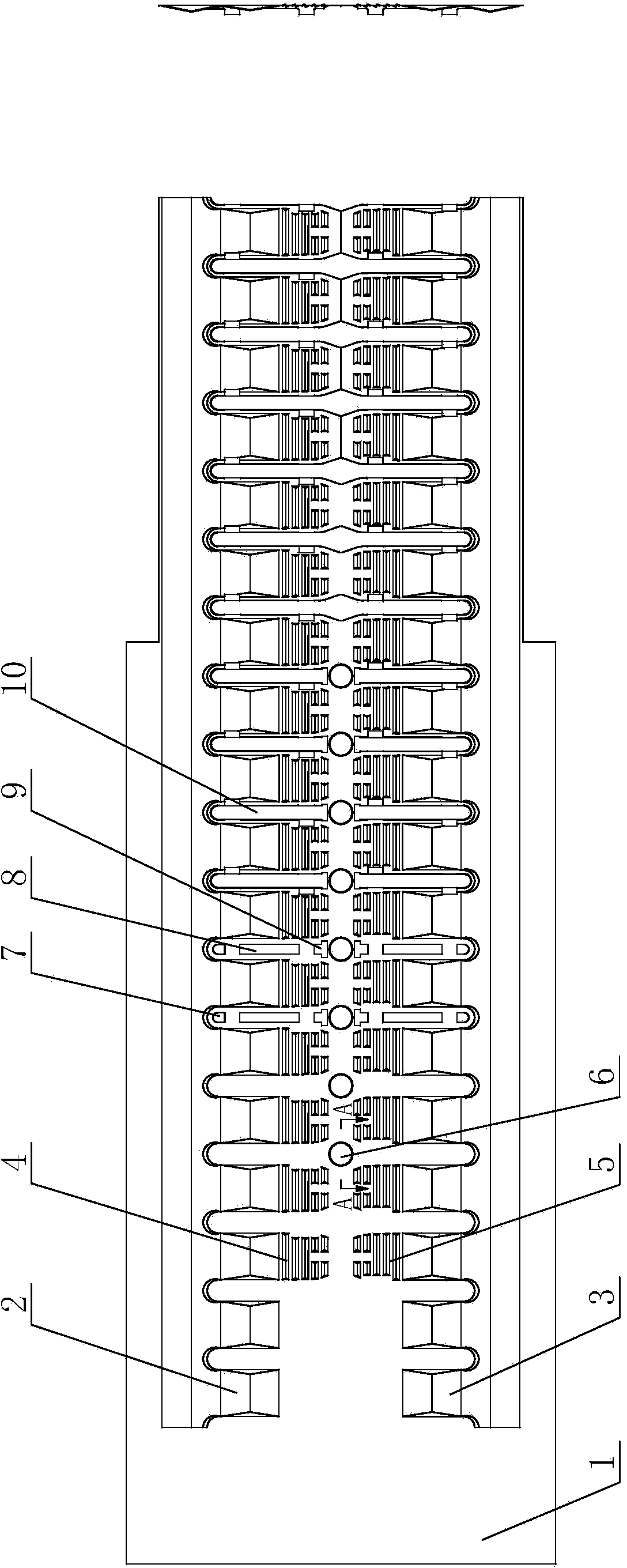

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0027] Please refer to Figure 2 to Figure 5 As shown, in the present embodiment, a kind of production process of air-conditioning fin, selects the aluminum strip material of strip structure as raw material, and its thickness is 0.08mm, passes the strip material 1 of strip structure through CNC press feeder in steps It is fed into the stamping die for continuous punching, and goes through the following processes in succession:

[0028] a. Punching corrugated sheets: symmetrically punch out the upper corrugated sheet 2 and the lower corrugated sheet 3 on the strip material 1;

[0029] b. Punching louvers: symmetrically punch out upper louvers 4 and lower louvers 5 between the upper corrugated sheet 2 and lower corrugated sheet 3 with materials, and the punched louvers 4, 5 and corrugated sheets 2, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com