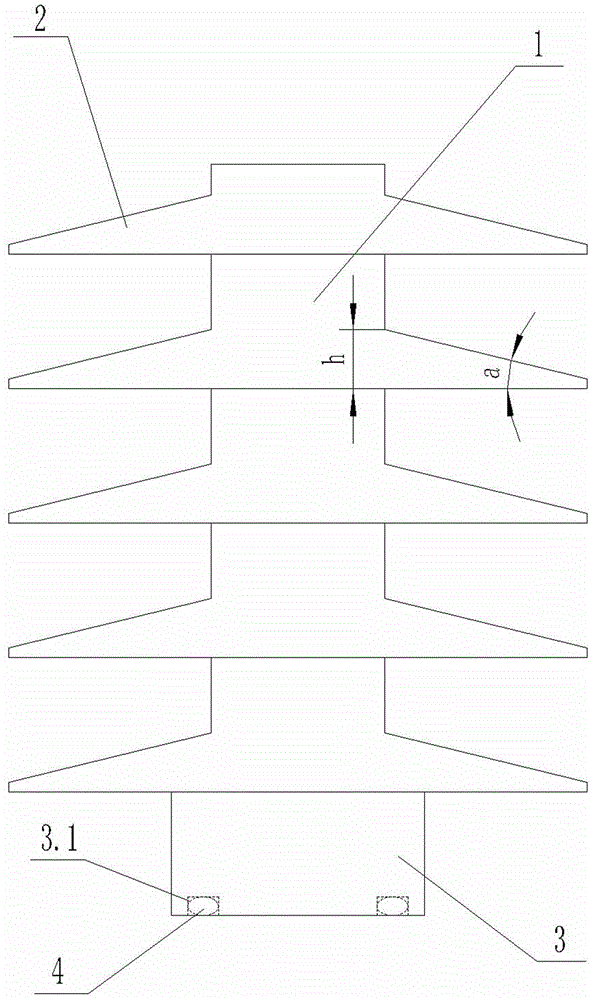

Insulation column for power equipment

A technology for power equipment and insulating columns, applied in the field of insulating columns, can solve problems such as creepage, pollution flashover, and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Insulating coating composition formula is as follows in parts by weight:

[0030] Film-forming resin: 40 parts of brominated bisphenol A epoxy resin; modifier: 6 parts of methylphenyl silicone resin; filler: 20 parts of porcelain powder; diluent: 15 parts of xylene; curing agent: aliphatic amine 9 parts of primary amine; plasticizer: 10 parts of dibutyl phthalate.

[0031] The preparation method is as follows:

[0032] (1) Add the film-forming resin, modifier, diluent and plasticizer into the dispersion tank according to the proportion, stir and disperse evenly;

[0033] (2) Add the mixture and filler in step (1) into the paint grinding tank, stir and grind until the fineness is less than or equal to 45um;

[0034] (3) Fully stir the mixture in step (2) and curing agent to form an insulating coating.

[0035] The method of use is as follows:

[0036] The insulating coating is applied to the outer surface of the ceramic insulator by conventional methods such as spray...

Embodiment 2

[0039] Insulating coating composition formula is as follows in parts by weight:

[0040] Film-forming resin: 45 parts of brominated bisphenol A epoxy resin; modifier: 8 parts of methylphenyl silicone resin; filler: 15 parts of porcelain powder; diluent: 15 parts of xylene; curing agent: aliphatic amine 8 parts of primary amine; plasticizer: 9 parts of dibutyl phthalate.

[0041] The preparation method is as follows:

[0042] (1) Add the film-forming resin, modifier, diluent and plasticizer into the dispersion tank according to the proportion, stir and disperse evenly;

[0043] (2) Add the mixture and filler in step (1) into the paint grinding tank, stir and grind until the fineness is less than or equal to 45um;

[0044] (3) Fully stir the mixture in step (2) and curing agent to form an insulating coating.

[0045] The method of use is as follows:

[0046] The insulating coating is applied to the outer surface of the ceramic insulator by conventional methods such as sprayi...

Embodiment 3

[0049] Insulating coating composition formula is as follows in parts by weight:

[0050] Film-forming resin: 36 parts of brominated bisphenol A epoxy resin; modifier: 5 parts of methylphenyl silicone resin; filler: 25 parts of porcelain powder; diluent: 15 parts of xylene; curing agent: aliphatic amine 10 parts of primary amine; plasticizer: 9 parts of dibutyl phthalate.

[0051] The preparation method is as follows:

[0052] (1) Add the film-forming resin, modifier, diluent and plasticizer into the dispersion tank according to the proportion, stir and disperse evenly;

[0053] (2) Add the mixture and filler in step (1) into the paint grinding tank, stir and grind until the fineness is less than or equal to 45um;

[0054] (3) Fully stir the mixture in step (2) and curing agent to form an insulating coating.

[0055] The method of use is as follows:

[0056] The insulating coating is applied to the outer surface of the ceramic insulator by conventional methods such as spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com