A method and device for separating sheet material

A technology for the separation of sheet materials, applied to instruments, handling coins or valuable banknotes, etc., can solve problems such as low sorting speed, affecting the positioning of sheet materials, improper adjustment by operators, etc., to reduce misjudgment rate, Stable performance and easy positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

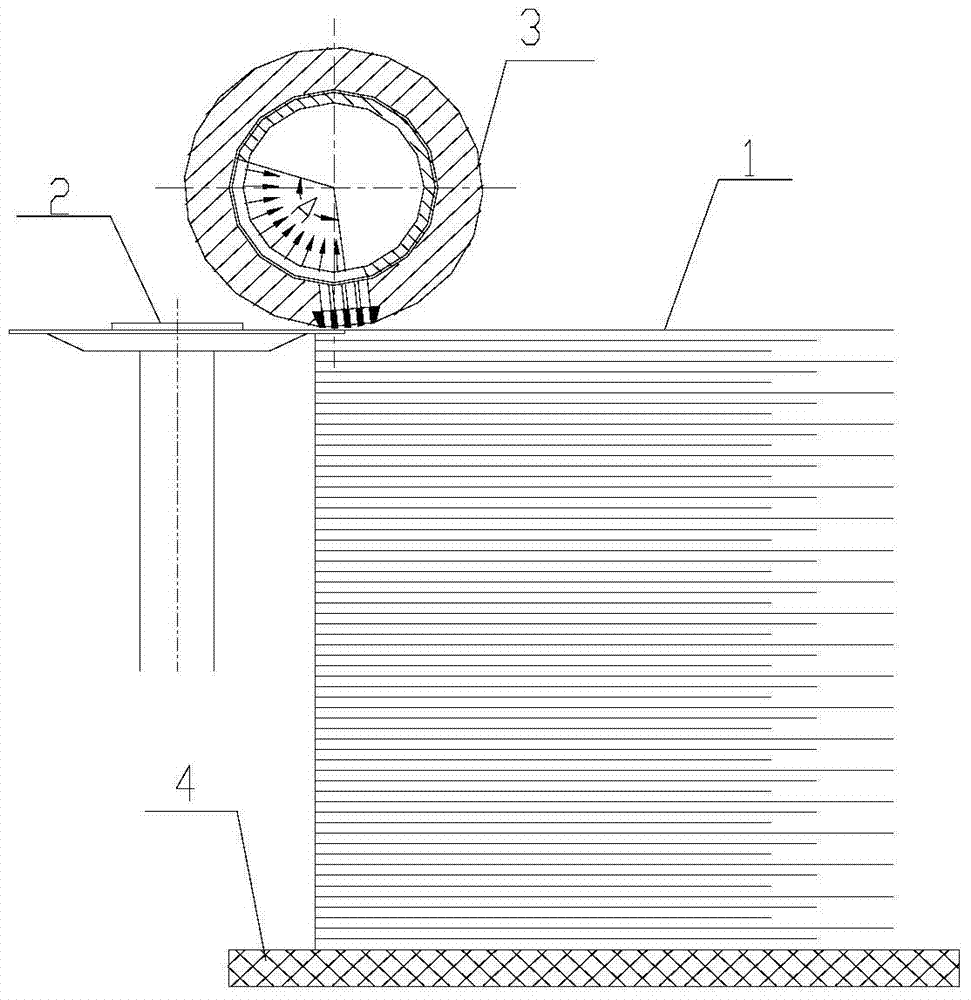

[0041] The device for separating sheet materials (hereinafter referred to as sorting device) provided by the present invention is intended to replace the technical solution of using friction wheels and pneumatic equipment for sorting in the prior art, and is a new sorting device for sheet materials. Pick up equipment. The sorting device uses the scanning suction cup 2 to separate a single piece of sheet material from the top layer of the sheet material stack 1, and uses the suction sorting wheel 3 to peel off the separated single piece of the top layer of the stack from the scanning suction cup 2. At the same time, the stacked sheet materials are continuously raised by the sheet material stack lifting mechanism 4, and the relative position between the top layer of sheet materials and the scanning suction cup 2 is maintained, thereby realizing continuous positioning and sorting of the sheet materials.

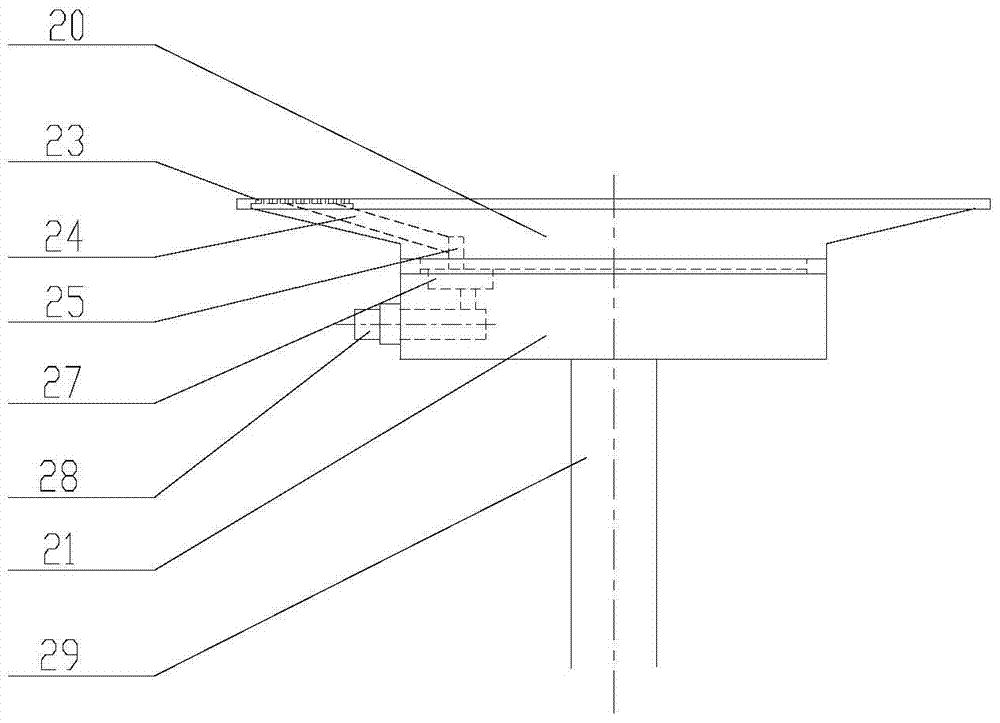

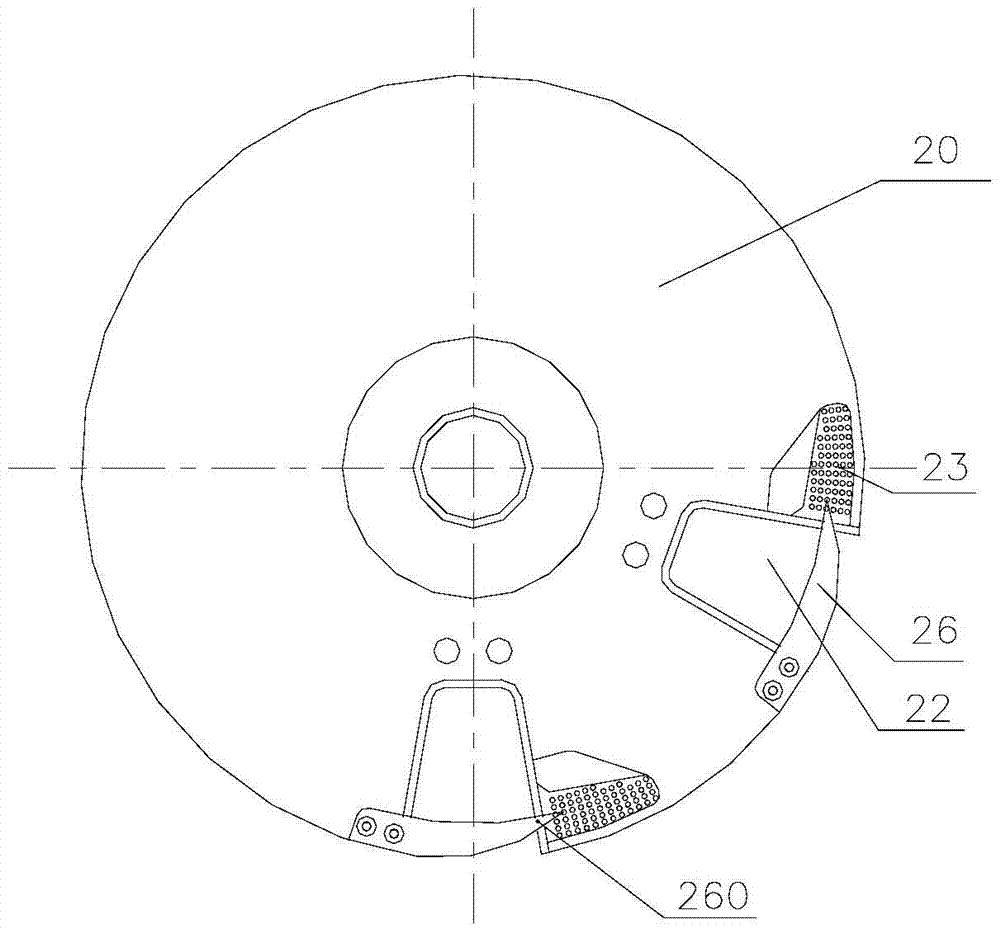

[0042] Such as figure 1As shown, the sorting device is composed of a scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com