An end face cam type multi-station sorting device

A technology of end face cam and sorting device, which is applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of low efficiency, time-consuming and labor-intensive efficiency, etc., and achieve the effects of stable transmission, continuous sorting, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

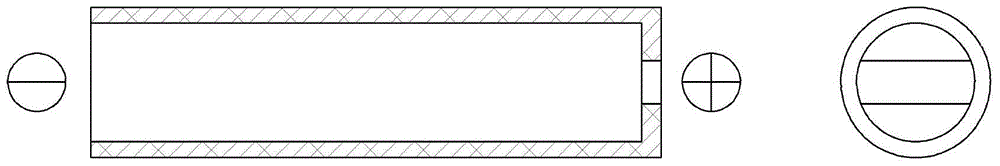

[0011] The invention can realize the sorting process of various workpieces such as rods and pipes, taking the firecracker bobbins currently produced in the market as an example. Such as figure 1 , the main body of the workpiece firecracker tube is a cylinder, the left end is a hollow end, and the right end is a slotted solid end. It is stipulated that the hollow end is negative and the solid end is positive. The forward and reverse distribution of workpieces is random during actual feeding. The purpose of this device is to separate the forward and reverse distributed workpieces that have been arranged and make them enter two different outlets to complete the sorting process.

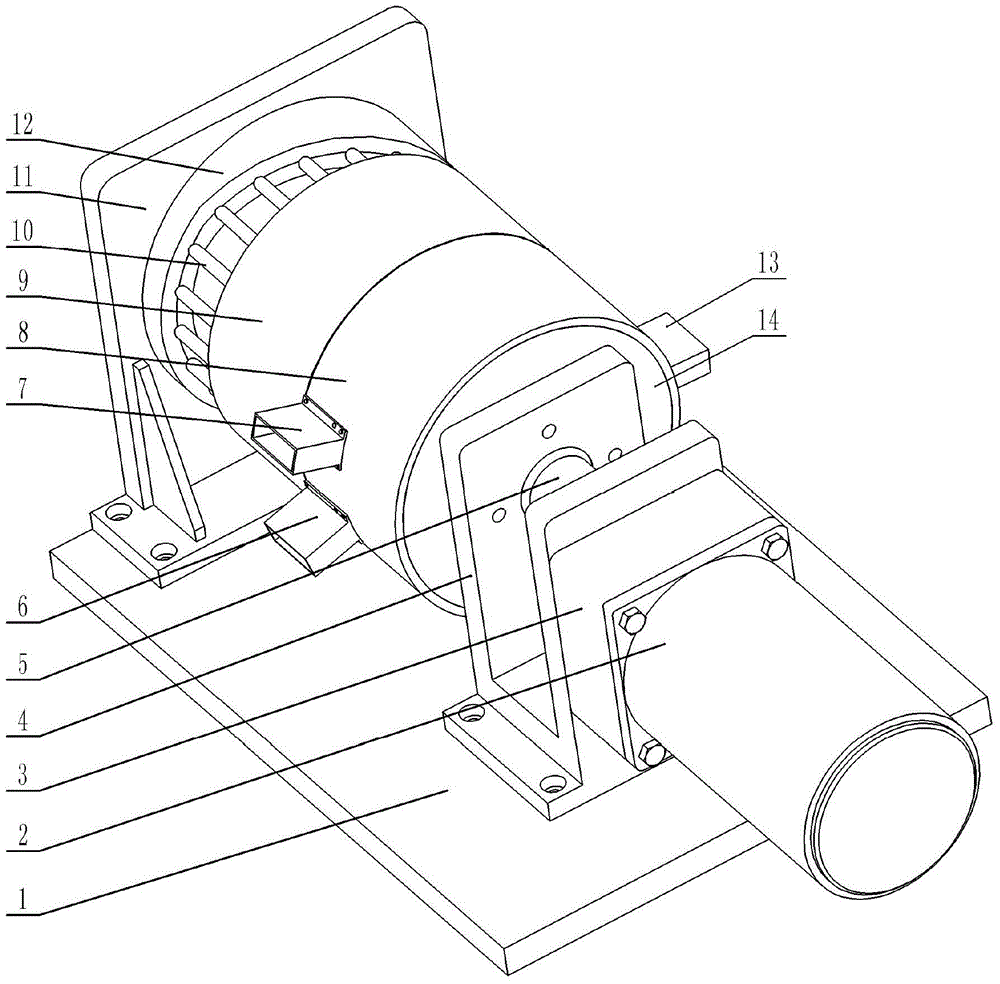

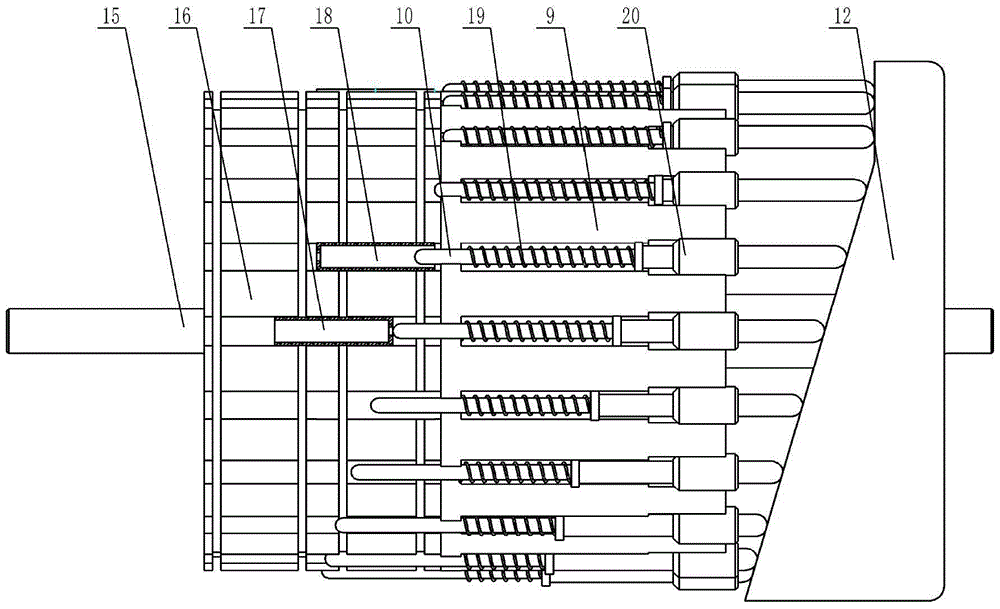

[0012] see figure 2 , image 3 , the base plate 1 is equipped with brackets 4 and 11, the motor 2 and the reducer 3 are installed on the bracket 4, and the shaft coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com