Method and device for real-time adjustment of lens installation flatness

A real-time adjustment and flatness technology, applied in optics, instruments, photography, etc., can solve problems such as complex operation, high calculation cost, and unsuitability for industrial automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

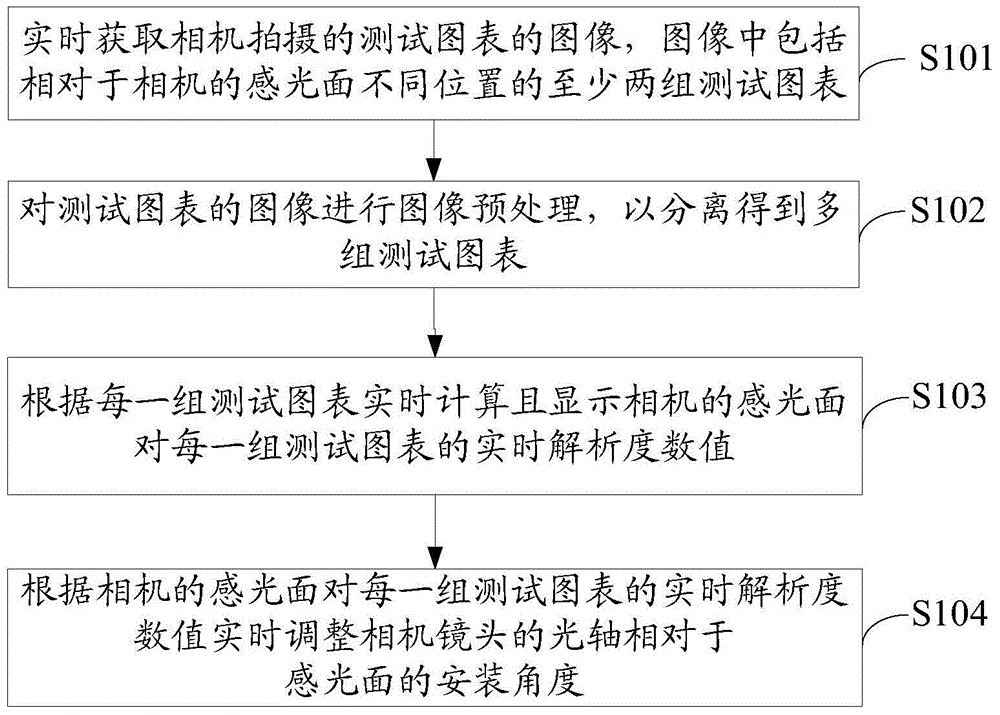

[0044] see figure 1 , figure 1 It is a flowchart of a real-time adjustment method for lens installation flatness provided by an embodiment of the present invention. This embodiment is described from the perspective of a real-time adjustment device for lens installation flatness. The real-time adjustment method for lens installation flatness in this embodiment include:

[0045] S101: Acquiring images of test charts taken by the camera in real time, the images including at least two groups of test charts at different positions relative to the photosensitive surface of the camera;

[0046] can refer to Figure 4 , Figure 4 It is a schematic diagram of the principle of camera imaging. The light from the object passes through the lens of the camera and then converges on the film to form an inverted and reduced real image. The optical axis of the camera lens runs through the object, the lens, and the center point of the image of the object.

[0047] It should be noted that whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com