Ice coating monitoring system and method for fan blade based on piezoelectric materials

A technology for fan blades and piezoelectric materials, which is applied in the field of fan blade ice coating monitoring systems based on piezoelectric materials, can solve problems such as load changes of power generation equipment, reduced power generation efficiency, mechanical failures, etc., and achieves low energy consumption and low power consumption. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

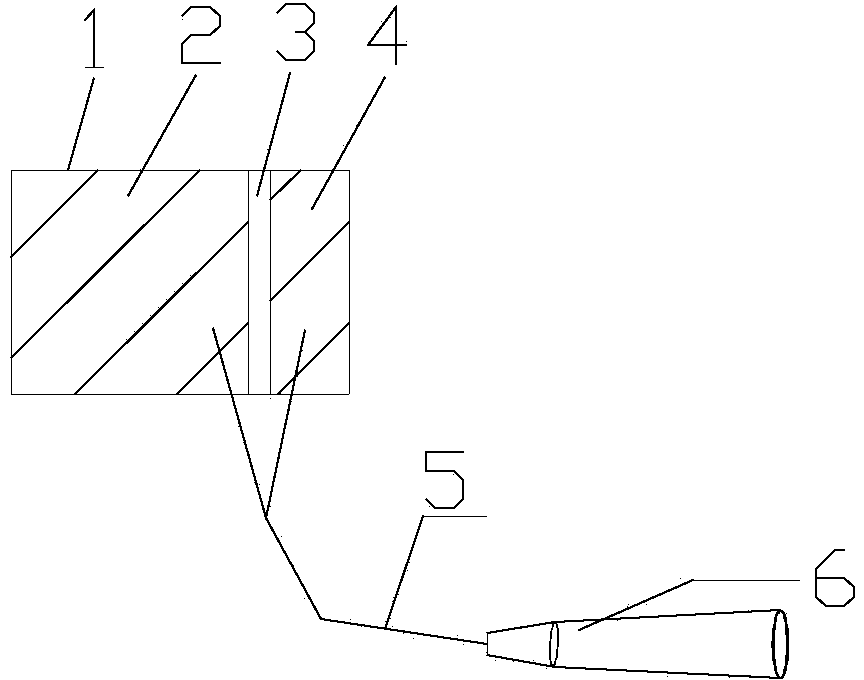

[0016] Such as figure 1 As shown, the piezoelectric driver or piezoelectric sensor according to the embodiment of the present invention includes a waterproof and insulating piezoelectric material 1, a shielded wire 5, and a connecting joint 6, and the same side of the piezoelectric material 1 is separated into a positive electrode 2 by a separation strip 3. and the negative pole 4, weld the two core wires at one end of the shielded wire 5 to the positive pole 2 and the negative pole 4 respectively, and connect the other end of the shielded wire 5 to the connecting joint 6.

[0017] The shape of the piezoelectric material 1 can be a cube, a circle, etc., and piezoelectric ceramic sheets and piezoelectric film sheets can be used, with or without flanging. When choosing to paste the piezoelectric material on the surface of the blade, the flanging piezoelectric ceramic sheet is preferred, because the electrodes are easy to paste on the surface of the blade structure after welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com