An automatic ignition device for atomized swirling micro-oil

An automatic ignition and micro-oil technology, which is applied in the direction of combustion ignition, igniter with fuel, combustion method, etc., can solve the problems that affect the economic benefits of enterprises, insufficient diesel combustion, poor atomization effect, etc., to ensure combustion Efficiency, strong adaptability, remarkable fuel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

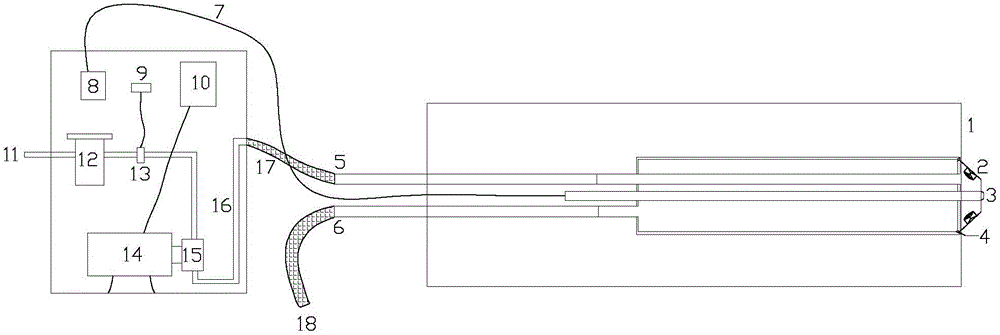

[0015] Such as figure 1 as shown, figure 1 It is a schematic diagram of the structure principle of the present invention.

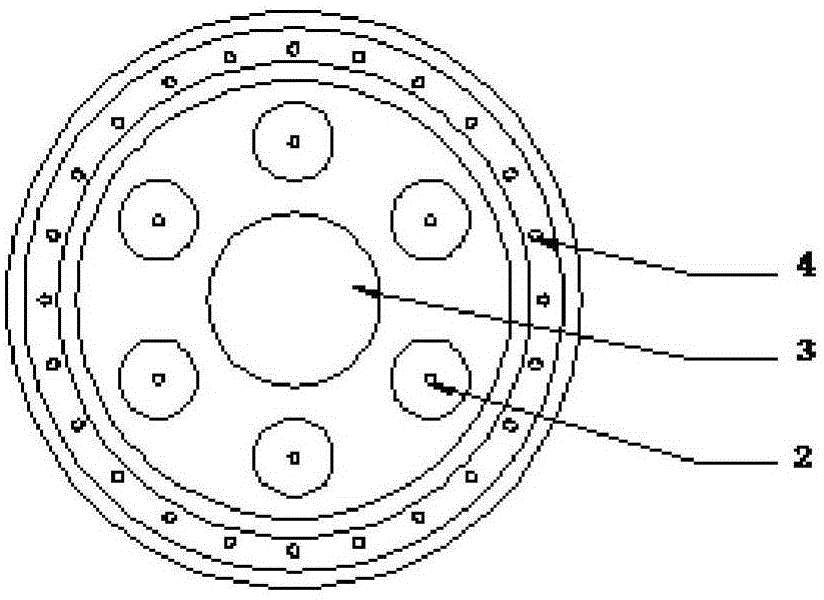

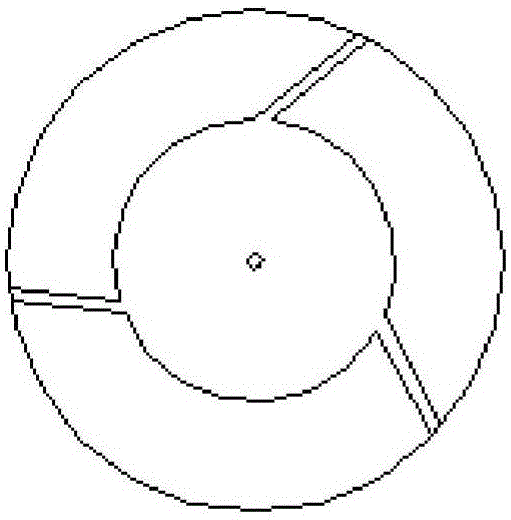

[0016] In the atomized swirling micro-oil automatic ignition device of this embodiment, diesel oil is pumped from the oil depot to the oil inlet pipe 11, filtered through the filter 12 in depth, passed through the flow meter 13, passed through the booster pump 15, passed through the oil outlet pipe 16, and connected to the flexible oil pipe. Pipe 17; the oil gun is installed in the coal injection pipe burner 1, and the diesel oil pressurized twice passes through the oil pipe hose 17 through the oil inlet pipe 5, and is atomized and sprayed from the oil injection hole 2, and the compressed air is sprayed from the air pipe soft The pipe 18 is connected and diverted from the compressed air hole 4 to increase the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com