Middle separation wall top original lining cavity backfilling construction method when single-hole tunnel is changed into multiple arches

A construction method and technology for tunnels, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problem of unsuitable cavity treatment method, achieve good economic benefits and popularization and application value, not easy to leak grouting, and reduce the effect of grouting dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

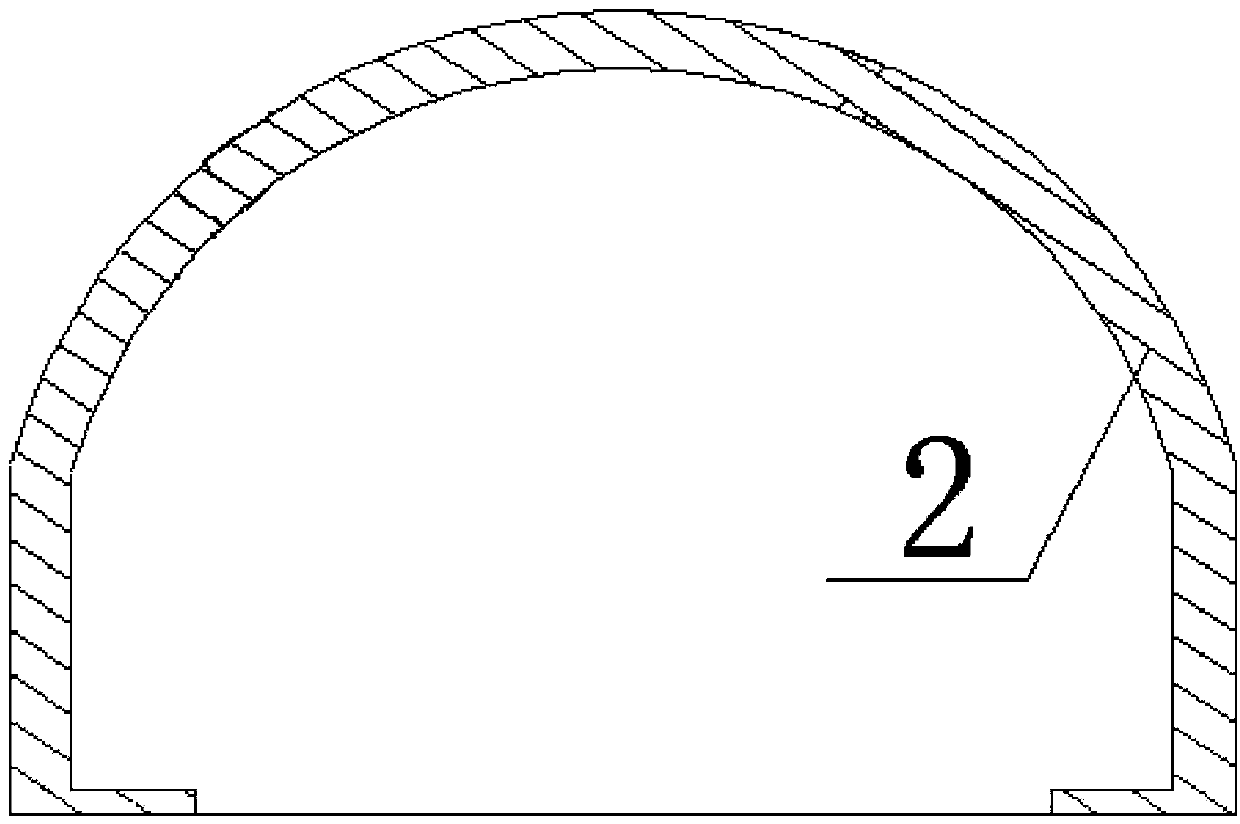

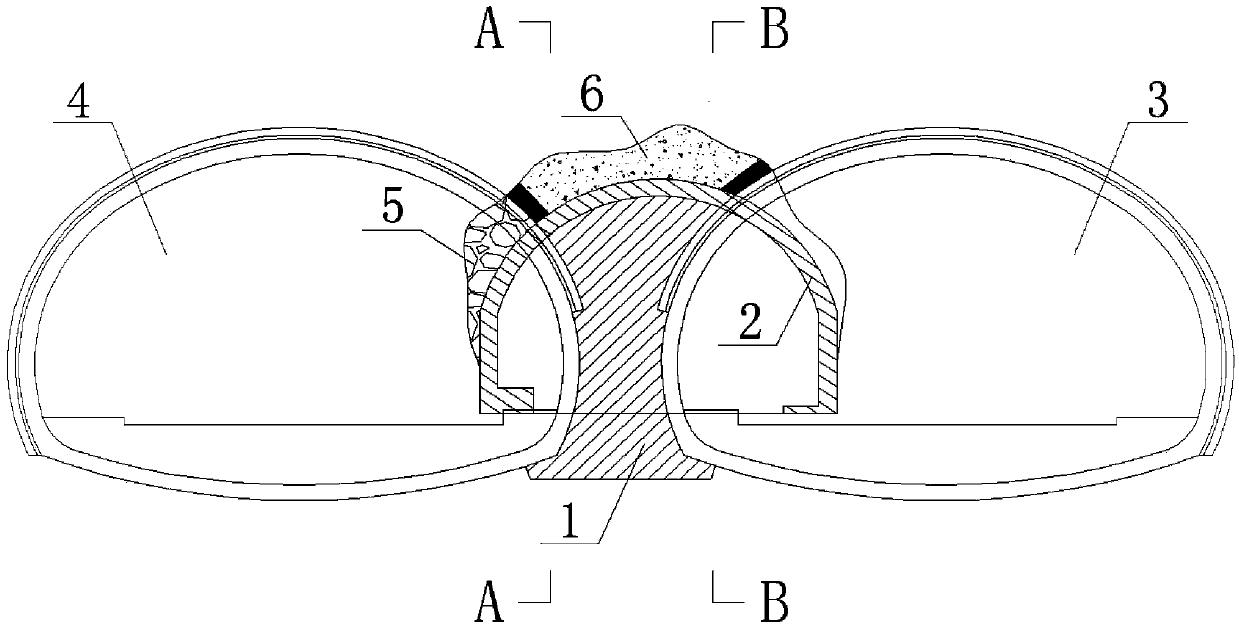

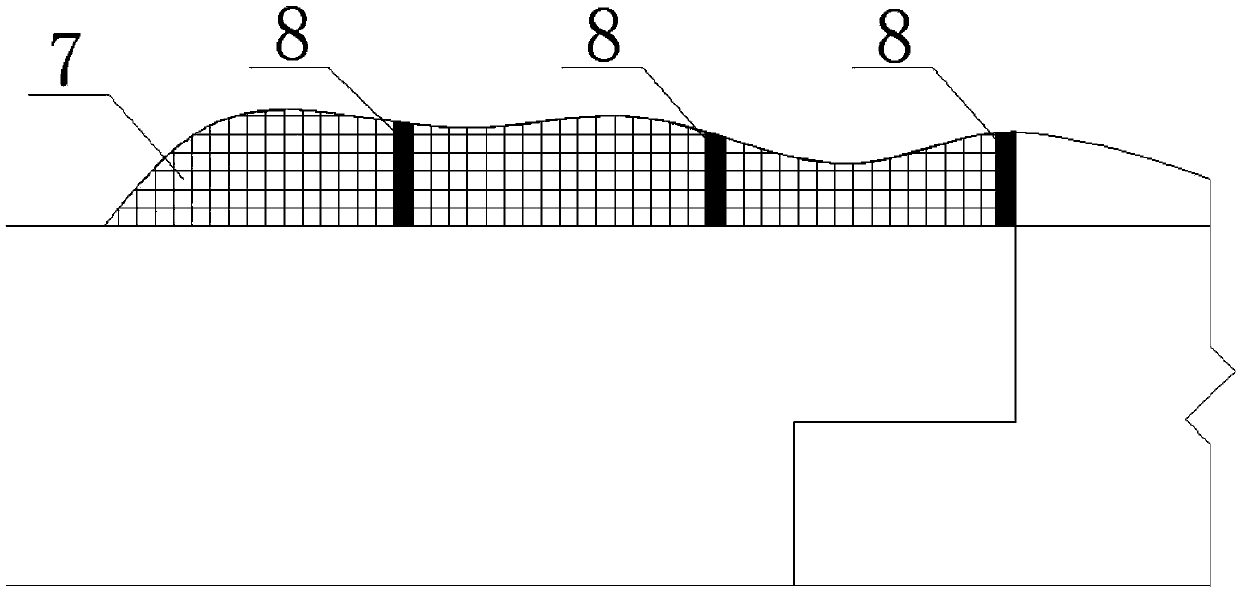

[0038] A tunnel is a multi-arch tunnel reconstruction and expansion project using the existing single-hole tunnel as the intermediate pilot tunnel. The total length of the tunnel is 125m. When the right hole (first hole) was excavated to the vicinity of K0+530, it was found that the top of the original tunnel lining was empty. The cavity is large in scale, with a void height of 30cm to 2m at the top of the cave, extending horizontally to below the left arch waist, and the length of the vertical extension is unknown. Due to the large span of the tunnel, the full width of the excavation is about 34.3m, if no backfill treatment is carried out, it may cause large settlement or even landslide during construction or operation. For this reason, the backfilling of the cavity has been successfully completed by adopting the construction method of the present invention. According to the results of on-site inspection, the filling effect of the cavity is good, and no obvious settlement an...

Embodiment 2

[0051] A tunnel is a multi-arch tunnel reconstruction and expansion project using the existing single-hole tunnel as the intermediate pilot tunnel. The total length of the tunnel is 130m. When the right hole (first hole) was excavated to the vicinity of K0+560, it was found that the top of the original tunnel lining was empty. The cavity is large in scale, with a void height of 30cm to 1m at the top of the cave, extending horizontally to below the left arch waist, and the length of the vertical extension is unknown. Adopt concrete construction method of the present invention as follows:

[0052] A construction method for backfilling the original lining cavity at the top of the partition wall when a single-cavity tunnel is changed to multiple arches, which includes the following steps in sequence:

[0053] a. Construct and pour the middle partition wall 1 at the horizontal middle position of the existing tunnel;

[0054] b. After the intermediate partition wall 1 is poured, s...

Embodiment 3

[0063] A tunnel is a multi-arch tunnel reconstruction and expansion project using the existing single-hole tunnel as the intermediate pilot tunnel. The total length of the tunnel is 150m. When the right hole (first hole) was excavated to near K0+600, it was found that the top of the original tunnel lining was empty. The cavity is large in scale, with a void height at the top of the cave ranging from 20cm to 1.5m, extending horizontally to below the left arch waist, and the length of the vertical extension is unknown. Adopt concrete construction method of the present invention as follows:

[0064] A construction method for backfilling the original lining cavity at the top of the partition wall when a single-cavity tunnel is changed to multiple arches, which includes the following steps in sequence:

[0065] a. Construct and pour the middle partition wall 1 at the horizontal middle position of the existing tunnel;

[0066] b. After the intermediate partition wall 1 is poured, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com