A Tunnel Model Test Method with Controllable Variation of Segment Joint Stiffness

A technology for segment joints and tunnel models, which is applied in tunnels, earth-moving drilling, mining equipment, etc., can solve problems such as changes, inability to provide accurate and reliable test basis for tunnel engineering design, construction and maintenance, and low reliability. To achieve the effect of accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

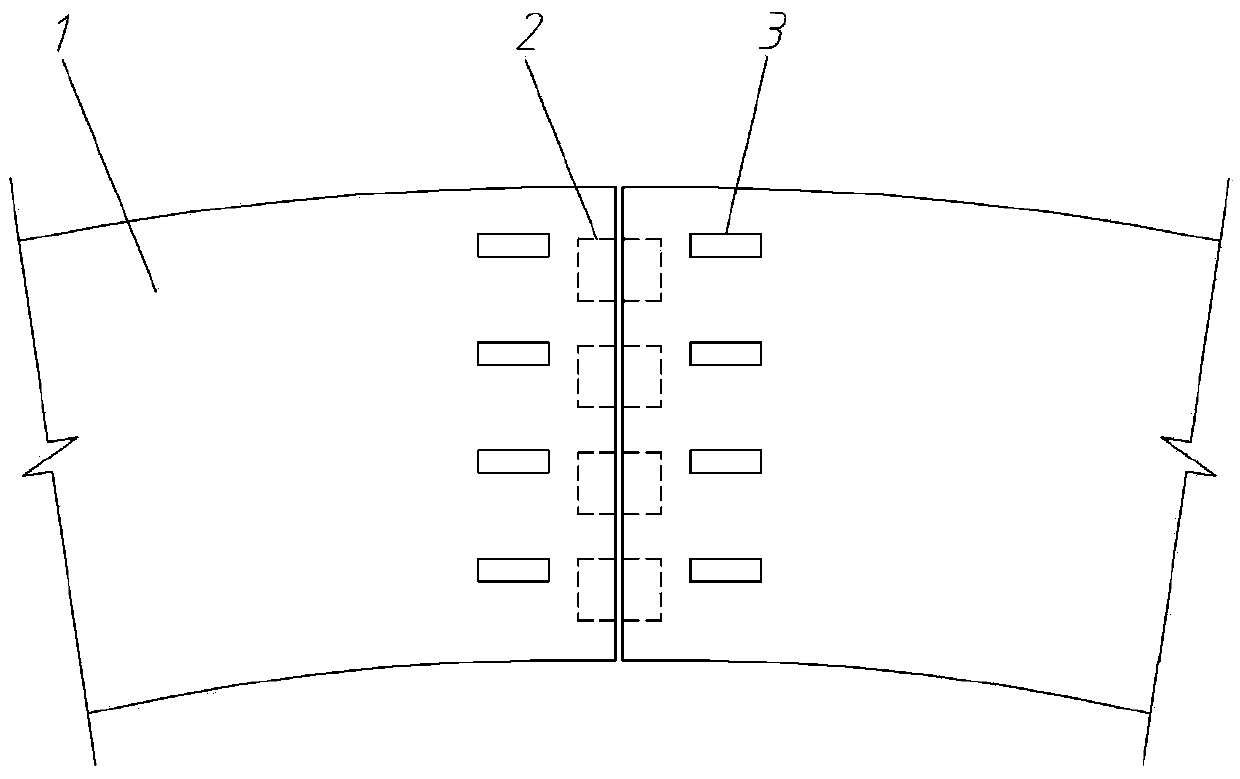

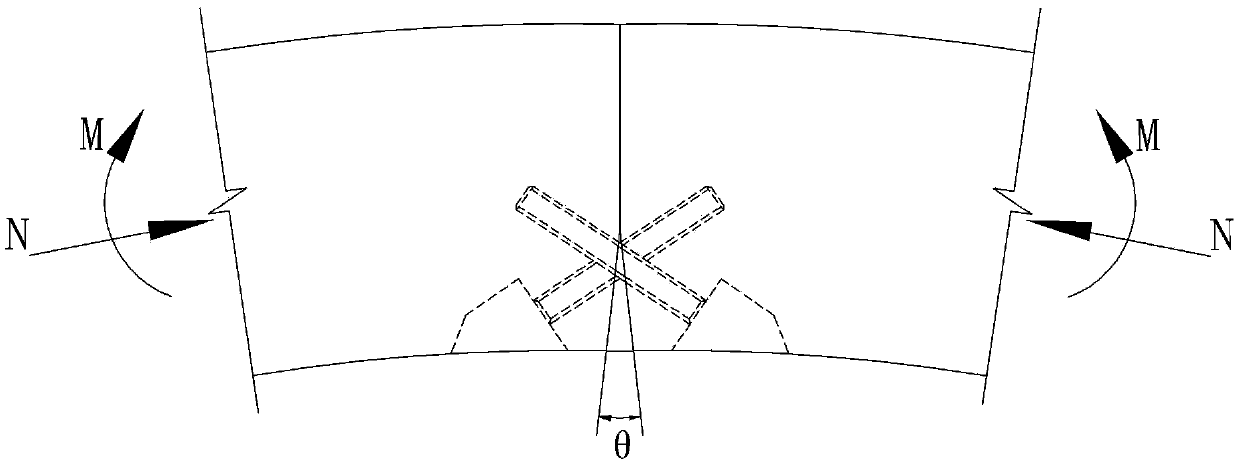

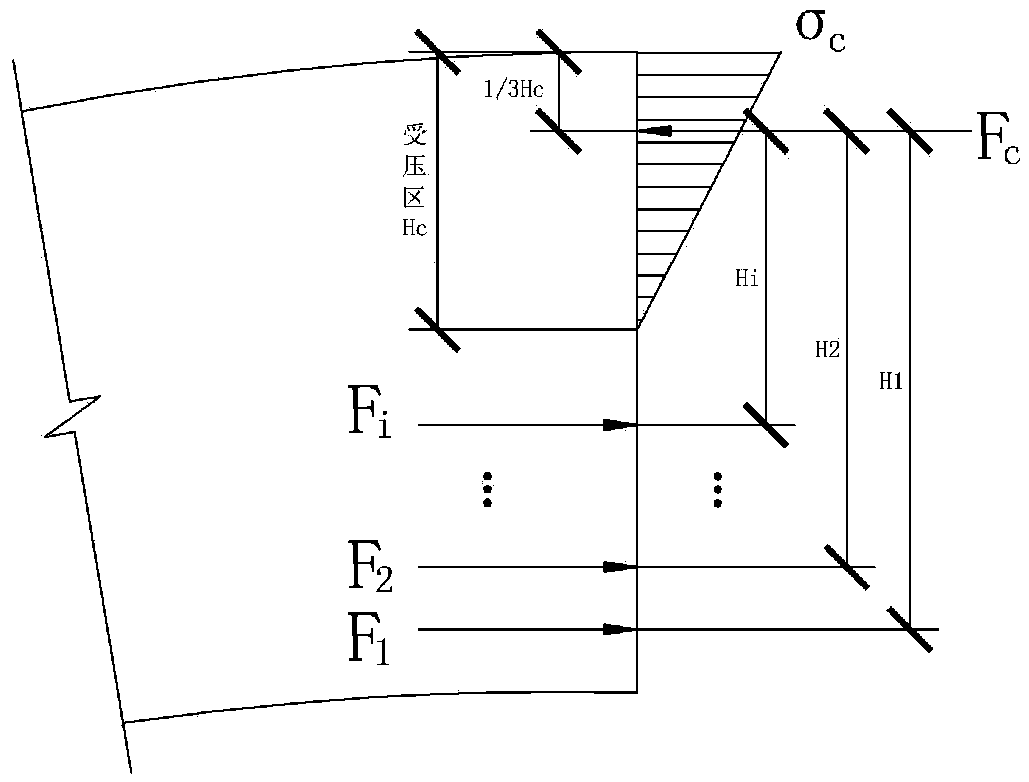

[0024] figure 1 It is shown that a specific embodiment of the present invention is a tunnel model test method with controllable variation of segment joint stiffness, the method of which is:

[0025] A. Make a model Make a separate model tunnel segment 1, and pre-embed an electromagnet 2 at the joint end of the model tunnel segment 1, and use a mold to align the model tunnel segment 1 into a model tunnel;

[0026] B. Instrument layout and initialization Arrange strain gauges 3 or displacement gauges on the side of the joint end of the model tunnel segment 1; pass a set initial current to the electromagnet 2, so that the magnetic force of the electromagnet simulates the initial stiffness of the joint between the segments;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com