Vanadium-titanium gray cast iron and production technique thereof

A production process and technology for gray cast iron, applied in the field of vanadium-titanium gray cast iron and its production process, can solve the problems of reducing thermal fatigue resistance, unfavorable strength, reducing thermal conductivity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

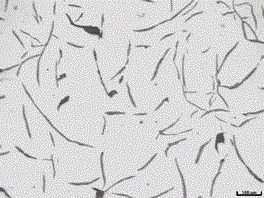

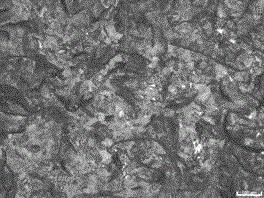

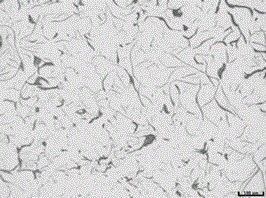

Image

Examples

Embodiment 1

[0039] A vanadium-titanium gray cast iron, including the following elements by weight percentage: C: 3.36%, Si: 1.60%, Mn: 0.85%, P: 0.069%, S: 0.077%, V: 0.163%, Ti: 0.076%, Cr: 0.275%, the balance is Fe and other trace elements and unavoidable impurities.

Embodiment 2

[0041] A vanadium-titanium gray cast iron, including the following elements by weight percentage: C: 3.41%, Si: 1.85%, Mn: 0.89%, P: 0.074%, S: 0.085%, V: 0.176%, Ti: 0.086%, Cr: 0.302%, the balance is Fe and other trace elements and unavoidable impurities.

Embodiment 3

[0043] A vanadium-titanium gray cast iron, including the following elements by weight percentage: C: 3.43%, Si: 2.00%, Mn: 0.88%, P: 0.078%, S: 0.088%, V: 0.185%, Ti: 0.082%, Cr: 0.293%, the balance is Fe and other trace elements and unavoidable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com