Mechanical automatic clamping grip

An automatic clamping and mechanical technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of high risk factor, low production efficiency, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

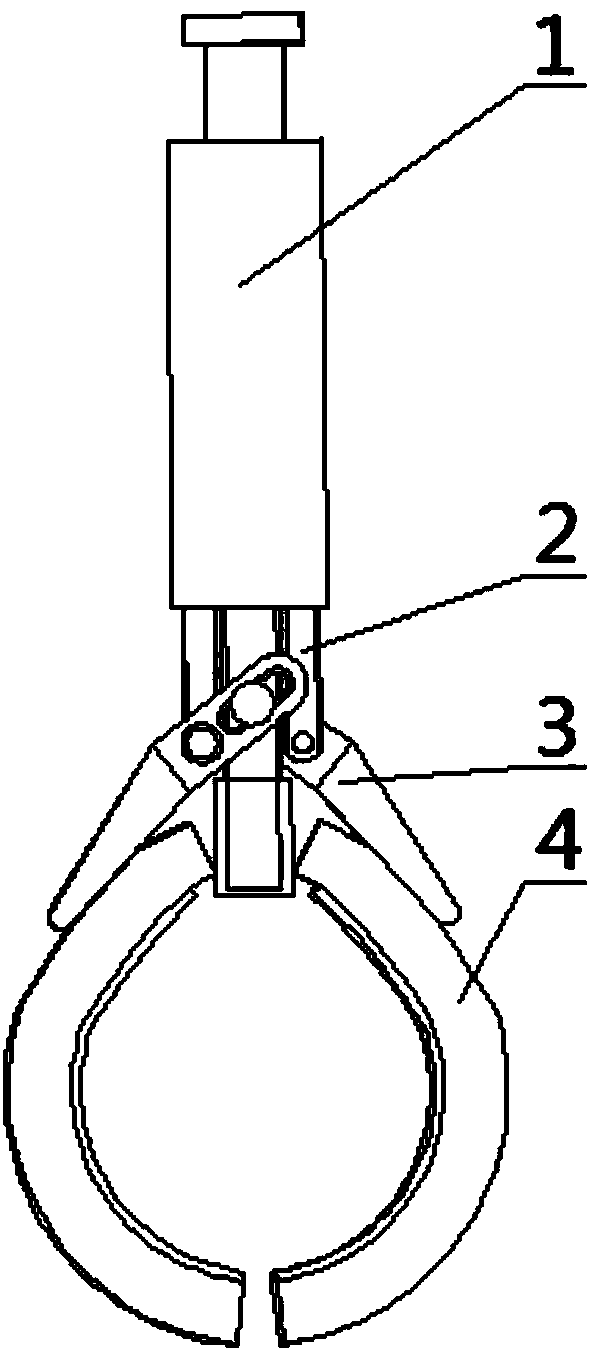

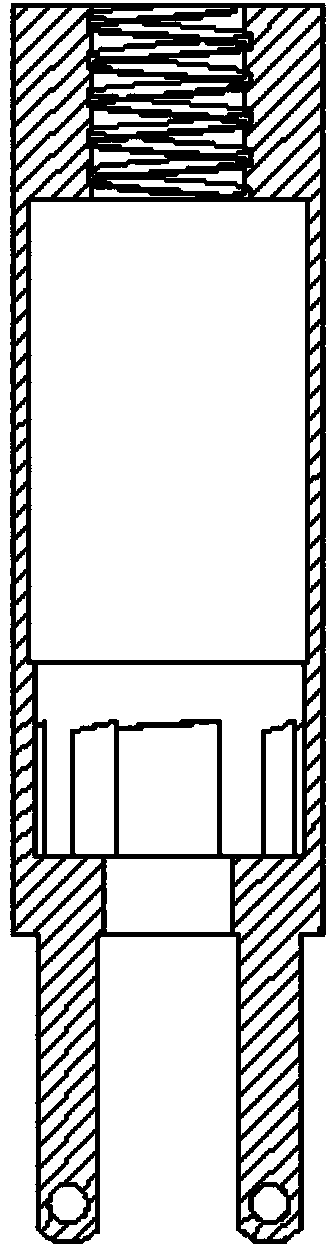

[0021] Such as figure 1 , figure 2 As shown, the mechanical automatic clamping gripper provided by the present invention includes a cage 1, a sliding cylinder 2, a claw 3, a snap ring 4, a connecting rod 5, a telescopic spring 6, a copper sleeve 7, a compression spring 8, and a sliding claw Rotary cylinder 9, sliding claw sleeve 10, mandrel 11 and copper top sleeve 14.

[0022] Such as figure 1 , image 3 , Figure 4 As shown, the cage 1 is a stepped cavity with threaded holes on the top; the outer wall of the slider 2 has four bosses, the bosses and grooves are arranged in a staggered manner, and each boss has two slide grooves. There are two extending arms at the lower end of the cylinder 2, and a threaded hole is respectively provided at the lower part of the two extending arms; the sliding cylinder 2 is fixedly connected in the cage 1.

[0023] Such as figure 1 As shown, the connecting rod 5 is threaded and connected to the threaded hole of the cage 1 of the cage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com