A method for roughening the surface of plastic rattan

A rattan and plastic technology, applied in the field of surface brushing of plastic rattan, can solve the problems of stiff visual sense of rattan, deformation of rattan products, easy breakage, etc. The effect of the brushed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

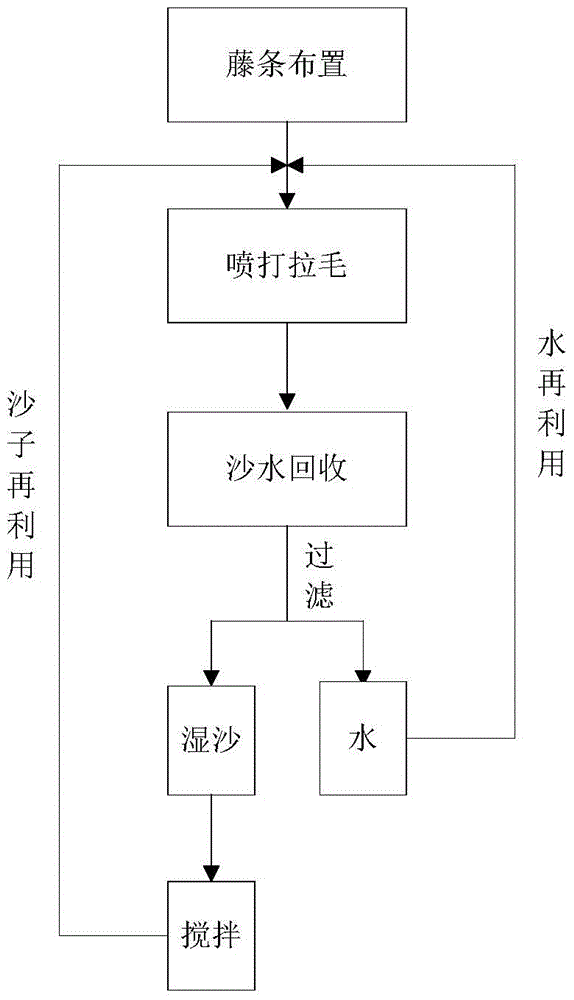

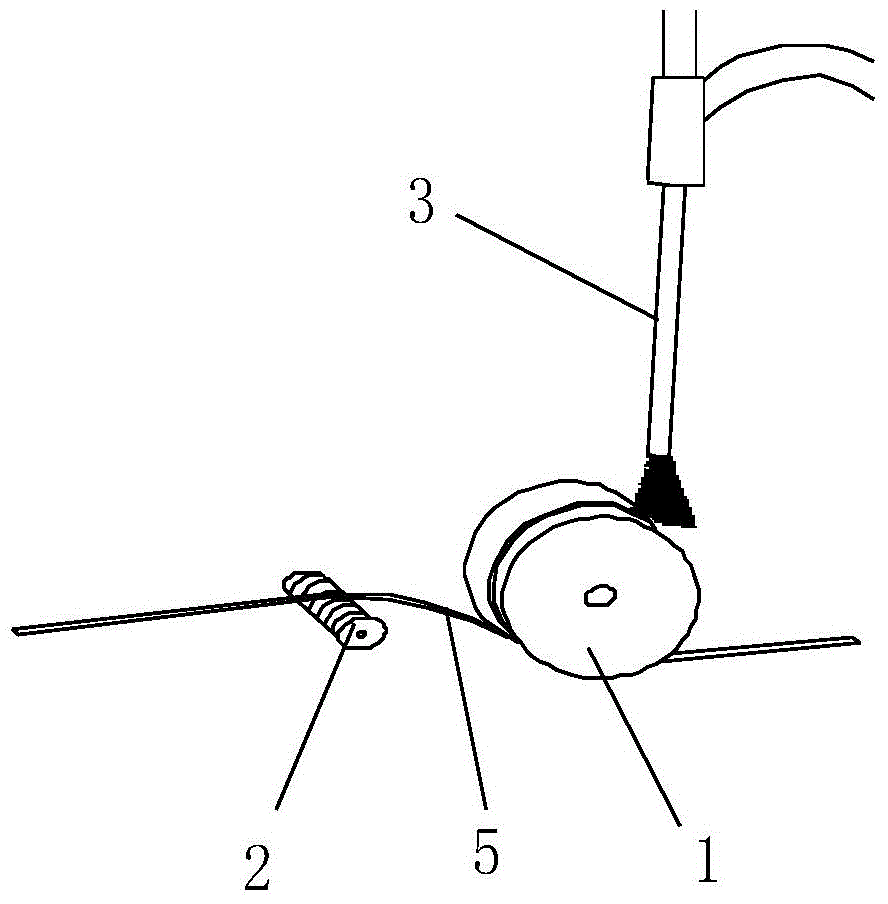

[0031] Refer to attached figure 1 to attach image 3 Shown, a kind of surface roughening method of plastic rattan comprises the following steps:

[0032] (1) Rattan layout: wind one end of the rattan 5 to be processed from the bottom of the runner 1, and the other end is drawn out from the other side of the runner 1, and the rattan is driven along the guide rod 2 after being drawn out;

[0033] (2) Spraying and napping: Utilize the high-pressure injection device 3 to spray the sand on the rattan surface wound on the runner 1 in the vertical direction, that is, after the sand is ejected from the nozzle, it is sprayed downwards on the rattan along the gravity effect. The rattan surface is brushed.

[0034] The angle range between the injection direction of the sand-water mixture and the surface of the rattan is 0°-90° to achieve the napping effect. As a preferred range, the angle between the injection direction of the sand-water mixture and the surface of the rattan is 30°-60...

Embodiment 2

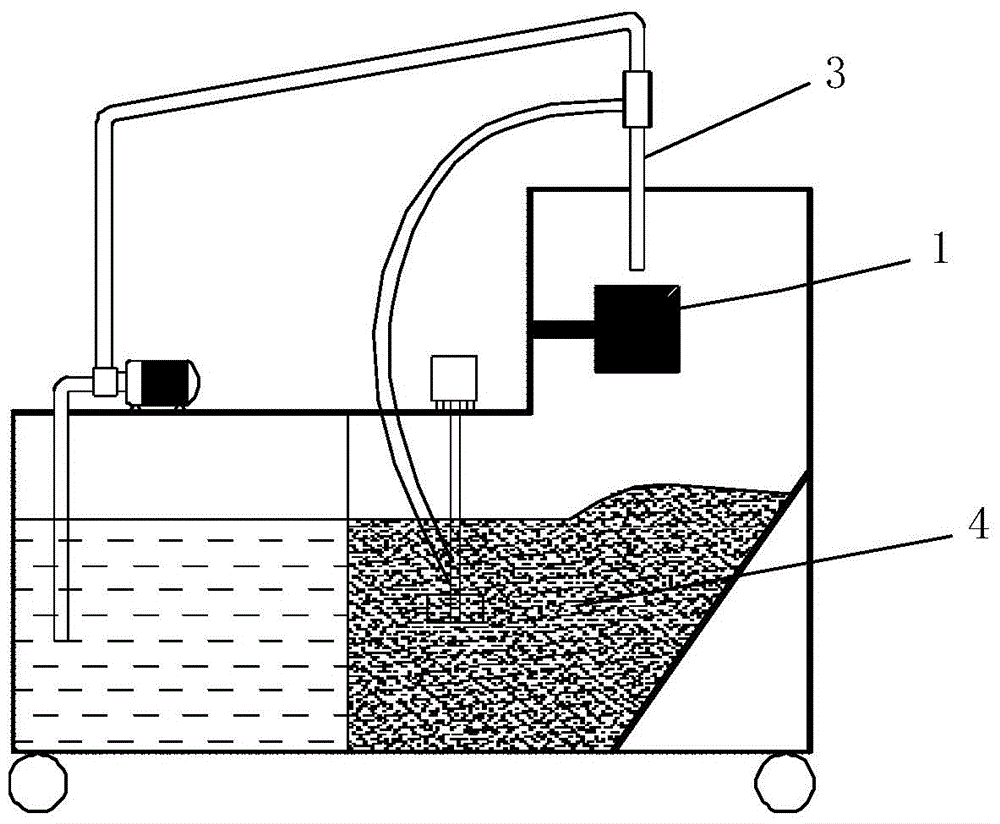

[0038] Refer to attached figure 1 , attached Figure 4 and attached Figure 5 Shown, a kind of surface roughening method of plastic rattan comprises the following steps:

[0039] (1) rattan arrangement: introduce the rattan 5a to be processed to the surface of the flat plate 1a through the guide hole, and drive on the surface of the flat plate 1a, one end of the flat plate 1a is fixed or rotatably connected to the nozzle of the high-pressure spraying device 3a The lower end, the guide hole is located at the connection between the flat plate 1a and the nozzle; the other end of the flat plate 1a is provided with a guide device, the guide device is a device that can fix the rattan such as perforation, guide wheel, chute, etc., and the rattan is from The guide device is drawn out, and the rattan is driven along the guide rod 2a after being drawn out.

[0040] (2) Spraying and napping: Utilize high-pressure spraying device 3a to spray sand along the vertical direction on the rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com