Cutting insert and interchangeable cutting edge-type cutting tool

A technology of cutting inserts and indexing inserts, which is applied in the direction of milling cutting inserts, manufacturing tools, milling cutters, etc., can solve problems such as difficult to further increase feed rate and high feed processing, and achieve the goal of reducing cutting resistance and improving chip discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

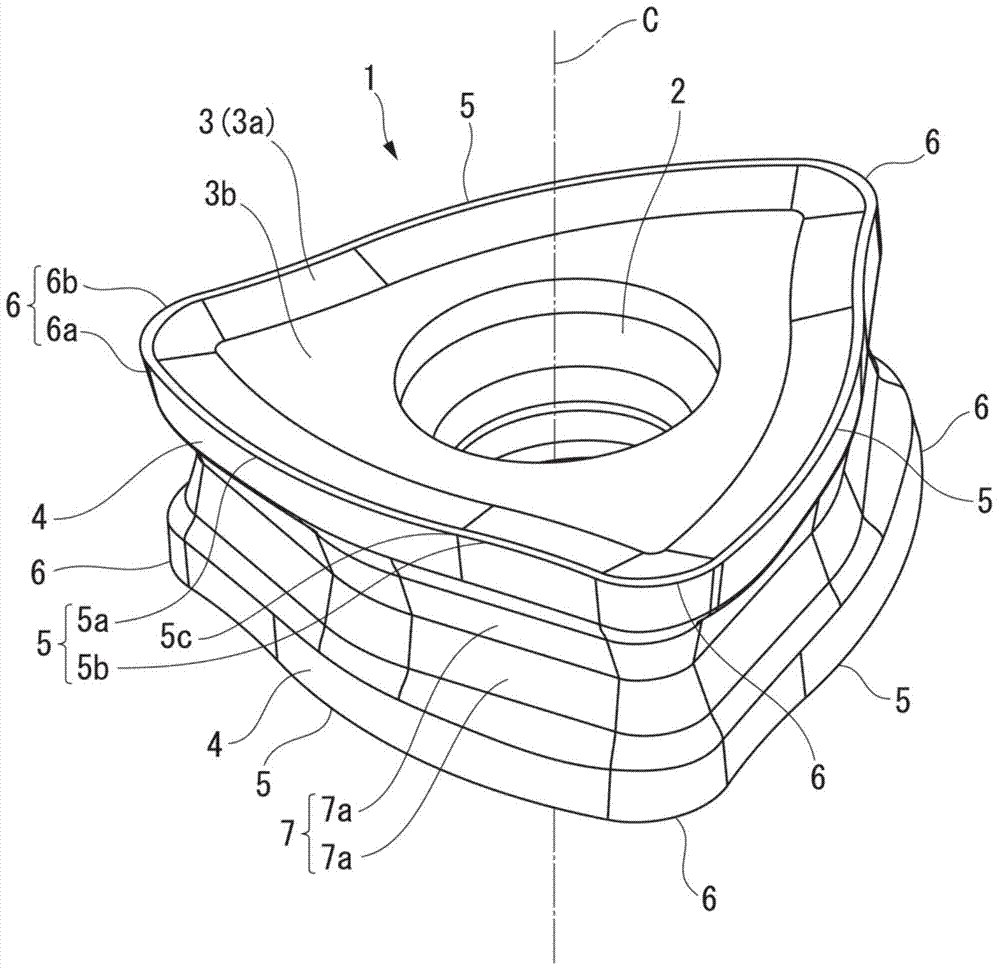

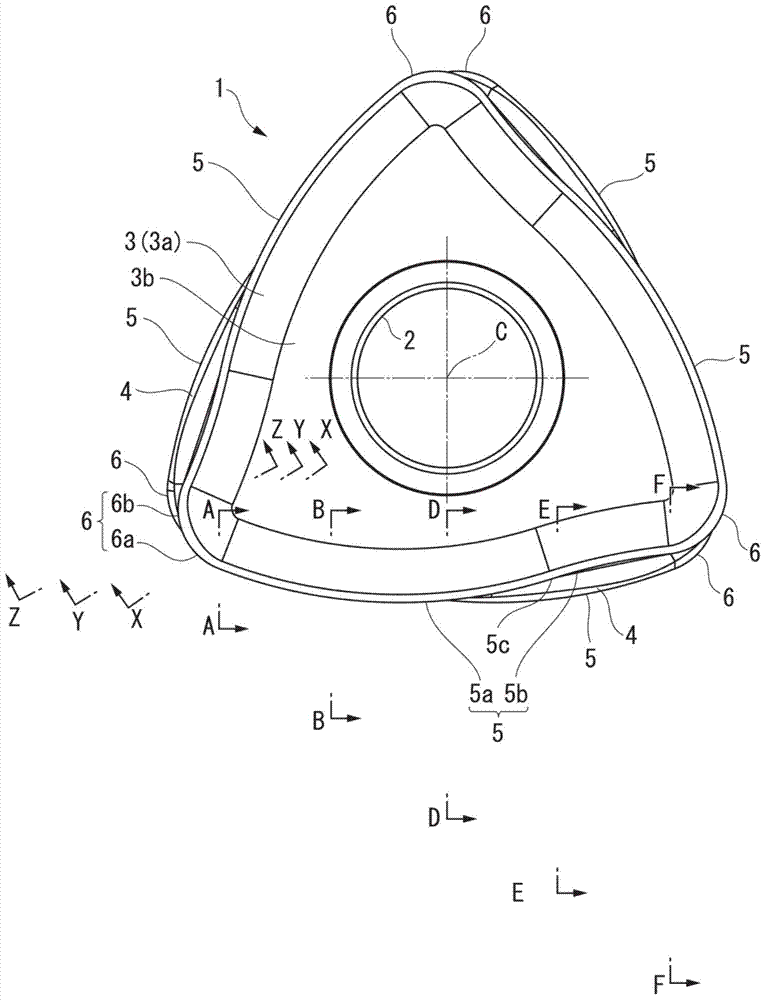

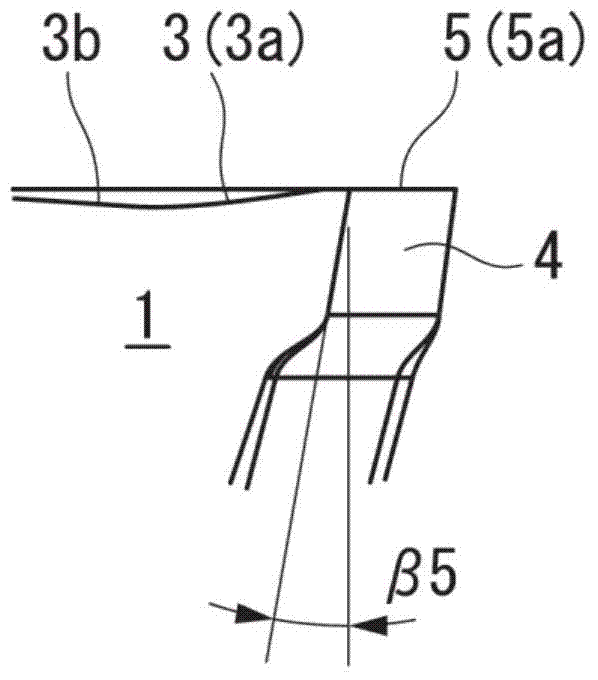

[0138] Figures 1 to 4C It is a figure which shows the 1st embodiment of the cutting insert of this invention, Figures 5 to 10C An indexable insert type end mill as a first embodiment of the indexable insert type cutting tool of the present invention equipped with the cutting insert of this embodiment is shown. In the cutting insert of this embodiment, the insert body 1 is formed in a polygonal plate shape by a hard material selected from cemented carbide, cermet, surface-coated cemented carbide, and surface-coated cermet. It is in the shape of a regular polygonal plate, and in this embodiment, it is in the shape of a regular triangular plate. Have a mounting hole 2 in the center of a pair of front and back polygonal faces (the first and second polygonal faces) of the blade body 1 in a regular triangle shape, and the mounting hole 2 is along the thickness direction of the blade body 1 ( figure 2 Orthogonal to the graph. Figure 3A ~ Figure 3E , Figure 4A ~ Figure 4C The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com