Method for comprehensive recycling of waste lithium-ion batteries

A lithium-ion battery and waste technology, which is applied in the field of recycling of renewable resources, can solve the problems of lack of environmental protection and economic comprehensive recycling methods, and achieve the effect of being suitable for industrial applications, process environmental protection, and solving treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

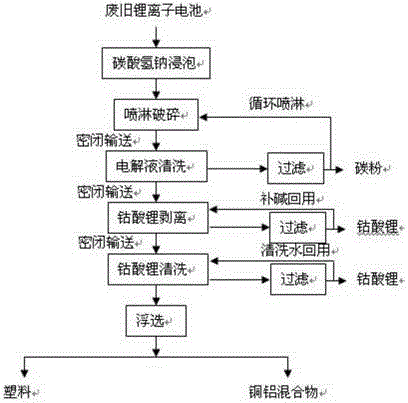

Image

Examples

Embodiment 1

[0051] a. Weigh 1000g of used lithium-ion batteries, soak them in sodium bicarbonate solution for 5 hours, and release the residual power to avoid battery short circuit during the crushing process.

[0052] b. In a closed shearing crusher, the waste lithium-ion battery is broken into flakes of 10-20mm by spraying, and the flake battery is sent to the electrolyte cleaning process with the spraying liquid.

[0053] c. Stir the spray liquid and sheet battery mixture fully for 0.6 hours, peel off the carbon powder on the surface of the copper foil, dissolve most of the electrolyte into the spray liquid, and recover the suspended spray liquid containing carbon powder and electrolyte through filtration Carbon powder, the mass fraction of carbon powder is 99.5%, detect and filter solution, do not detect fluorine ion, hexafluorophosphate ion 10.3g.

[0054] d. Airtightly conveying the filtered sheet-shaped battery into a 4% sodium hydroxide solution by mass fraction, stirring for 10 m...

Embodiment 2

[0058] a. Weigh 1000g of used lithium-ion batteries, soak them in sodium bicarbonate solution for 8 hours, and release the residual power to avoid battery short circuit during the crushing process.

[0059] b. In a closed shearing crusher, the waste lithium-ion battery is broken into flakes of 10-20mm by spraying, and the flake battery is sent to the electrolyte cleaning process with the spraying liquid.

[0060] c. Stir the mixture of the spray liquid and the sheet battery for 1.2 hours, peel off the carbon powder on the surface of the copper foil, dissolve most of the electrolyte into the spray liquid, and recover the suspended spray liquid containing carbon powder and electrolyte through filtration Carbon powder, the mass fraction of carbon powder is 99.5%, detect and filter solution, do not detect fluoride ion, hexafluorophosphate ion 10.5g.

[0061] d. Airtightly conveying the filtered sheet-shaped battery into a 3% sodium hydroxide solution by mass fraction, stirring for...

Embodiment 3

[0065] a. Weigh 1000g of used lithium-ion batteries, soak them in sodium bicarbonate solution for 11 hours, and release the residual power to avoid battery short circuit during the crushing process.

[0066] b. In a closed shearing crusher, the waste lithium-ion battery is broken into flakes of 10-20mm by spraying, and the flake battery is sent to the electrolyte cleaning process with the spraying liquid.

[0067] c. Stir the mixture of the spray liquid and the sheet battery for 1.8 hours, peel off the carbon powder on the surface of the copper foil, dissolve most of the electrolyte into the spray liquid, and recover the suspended spray liquid containing carbon powder and electrolyte through filtration Carbon powder, the mass fraction of carbon powder is 99.4%, detects filtered solution, does not detect fluorine ion, hexafluorophosphate ion 10.6g.

[0068] d. Airtightly conveying the filtered sheet battery into a 2% sodium hydroxide solution by mass fraction, stirring for 50 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com