Remote control method for electromechanical equipment maintenance

A maintenance and remote control technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems that equipment manufacturers can't do anything, achieve uniqueness, ensure operation reliability, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

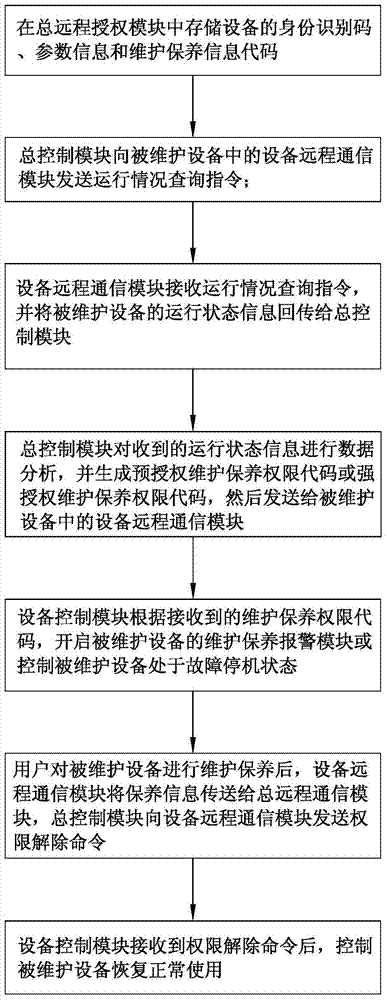

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

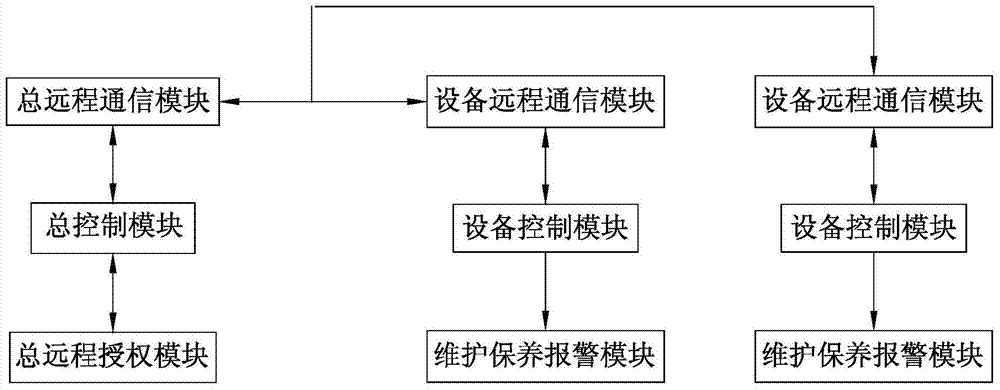

[0023] As shown in the figure, this embodiment uses a punching machine as an example to realize the remote control method for the maintenance of the punching machine, including the following specific steps:

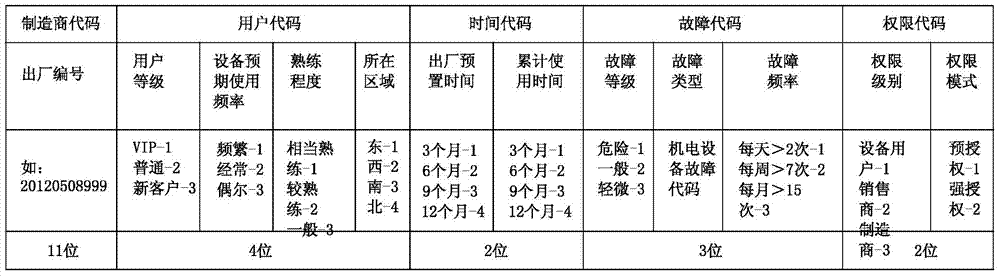

[0024] (1) Equip the manufacturer or seller of the press equipment with a general control module, a total remote authorization module and a total remote communication module, and equip the maintained punch equipment with a device control module, a device remote communication module and a maintenance alarm module , and pre-store the identification code, parameter information and maintenance information code of the punch press in the total remote authorization module. The maintenance information code is composed of five parts in sequence: manufacturer code, user code, time code, fault code and authority code , the manufacturer code is the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com