Pipe body bending detecting tool

A technology for detecting tooling and pipe body, which is applied in the direction of measuring devices, using stable bending force to test the strength of materials, instruments, etc., which can solve the problem that the bellows cannot be bent at ±90 degrees, the utilization rate of personnel is not high, and the bellows are inconsistent Issues such as outward pull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

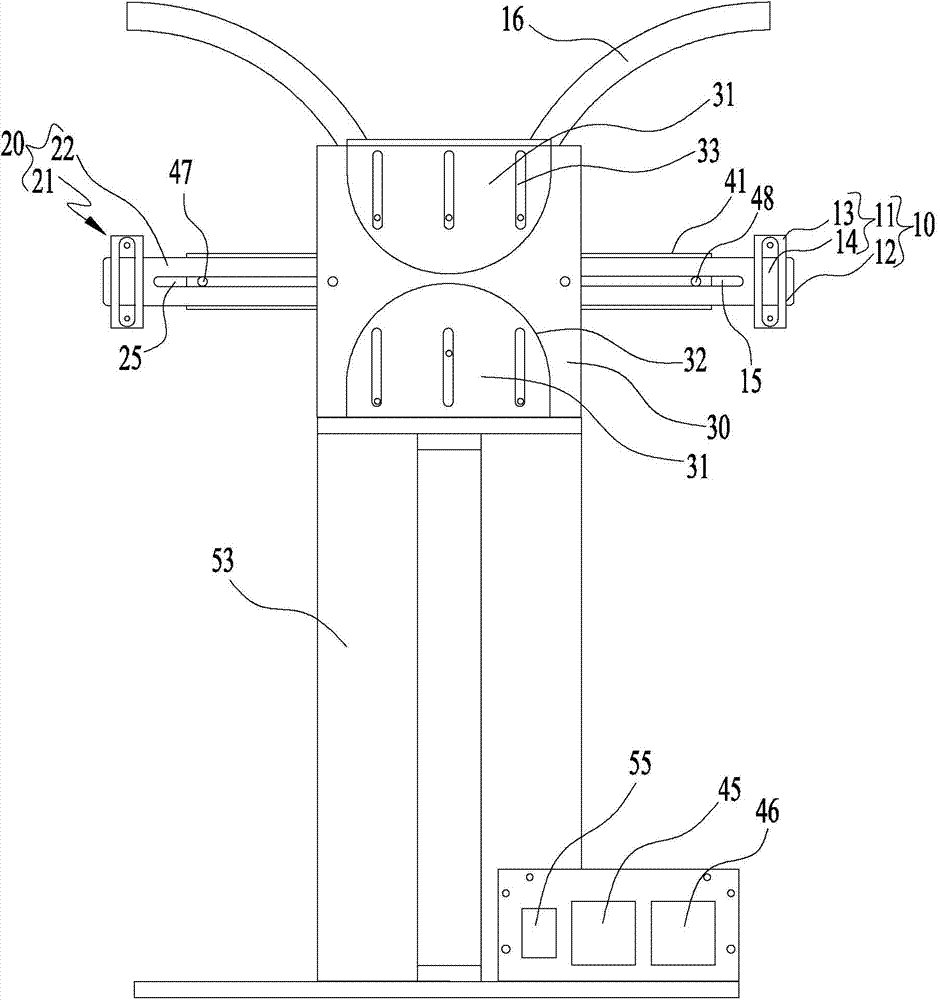

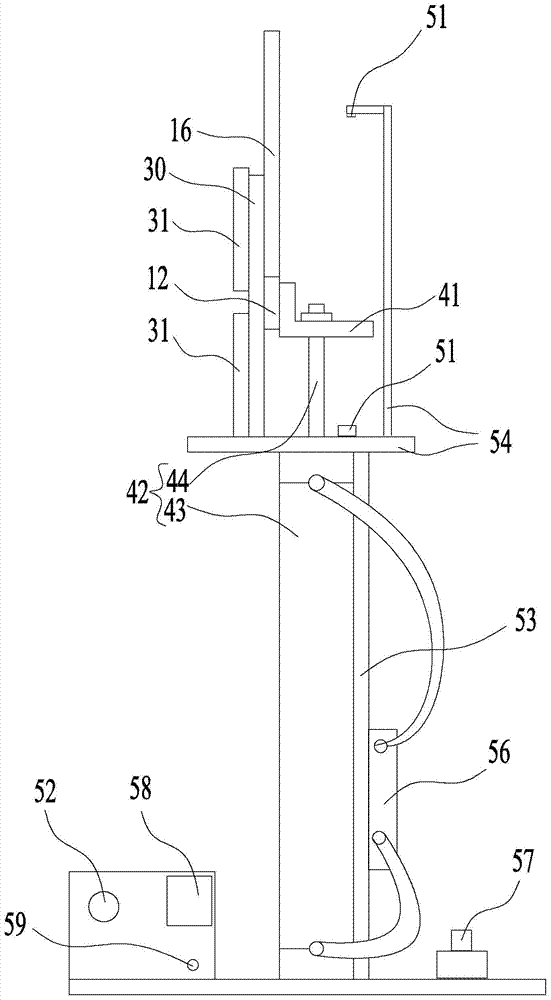

[0021] Such as figure 1 As shown, the tube bending detection tool of this embodiment includes a first tube fixing part 10, a tube second fixing part 20, a tube limiting part 30 and a driving device. The first pipe body fixing part 10 includes a pipe body first fixing part 11 , and the pipe body first fixing part 10 is pivotally arranged. The second tube body fixing part 20 includes a tube body second fixing part 21, and the tube body first fixing part 11 has a first to-be-bending position opposite to the tube body second fixing part 21 on the first extending straight line and deviates from the second tube body fixing part 21. A first bending position and a second bending position extending a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com