Novel capacitive liquid level sensor based on capacitance calculation principle and application thereof

A liquid level sensor and a technology for calculating capacitance, which is applied in the direction of liquid level indicators for physical variable measurement, can solve the problems of reduced accuracy and achieve the effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

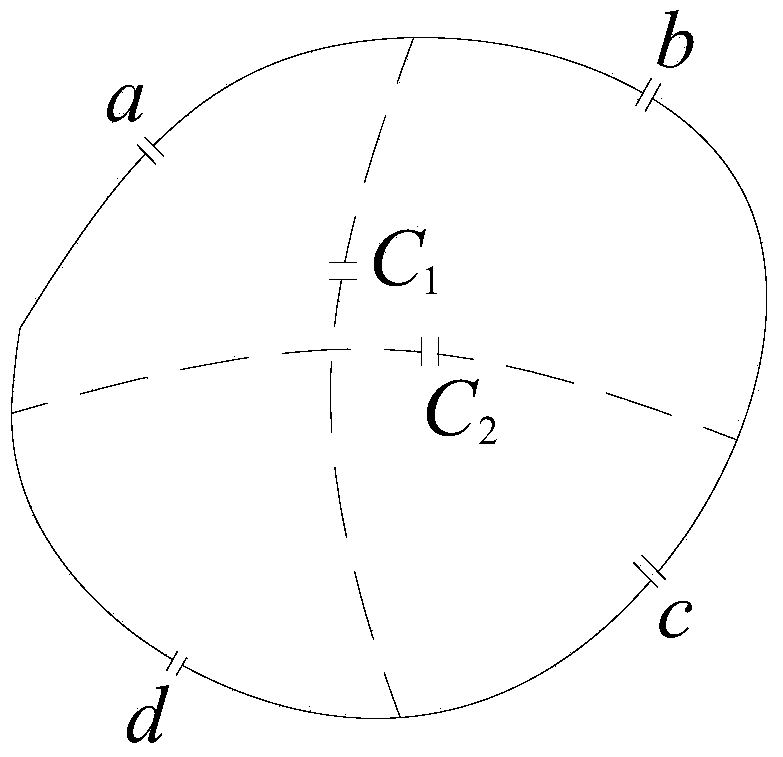

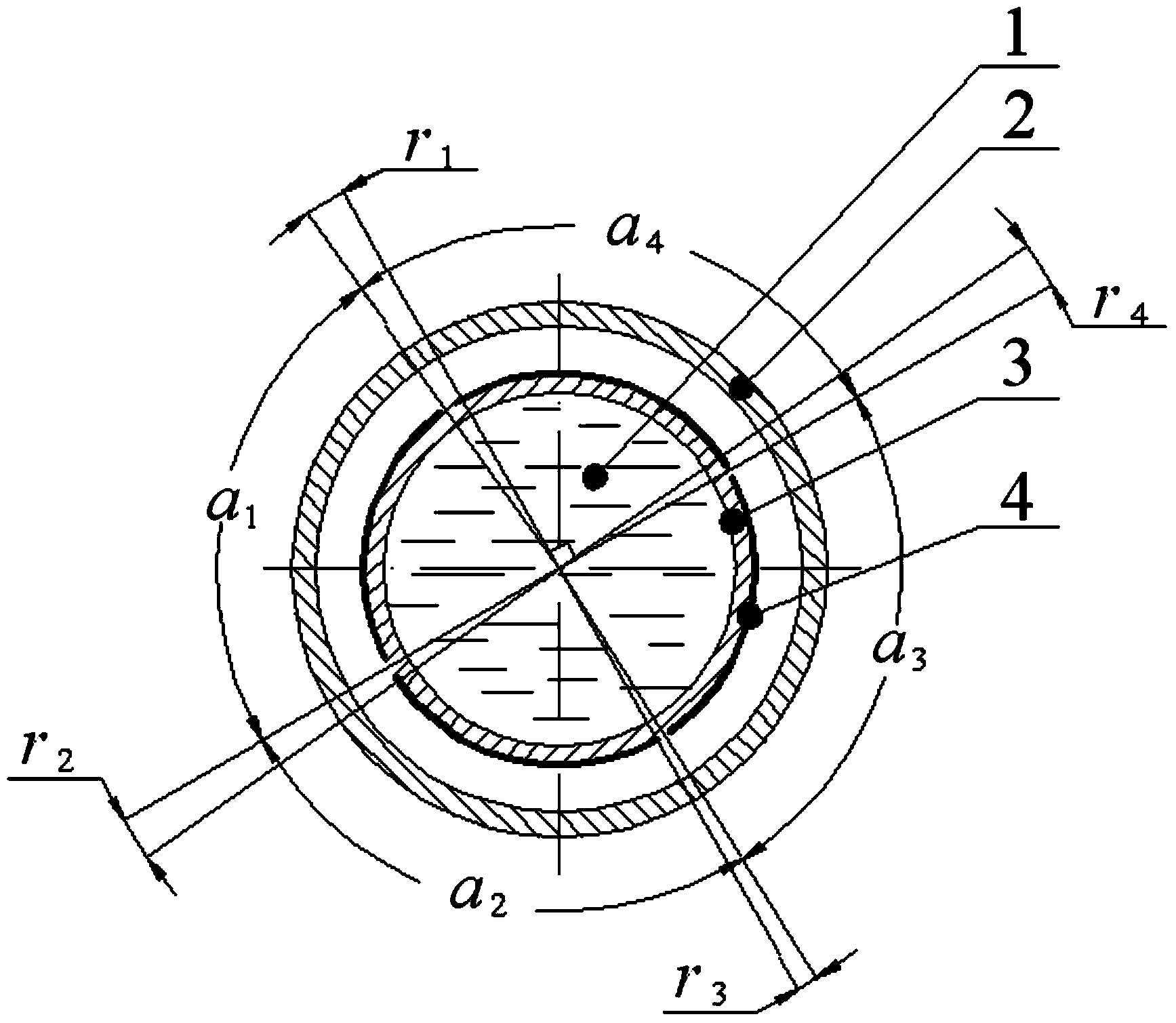

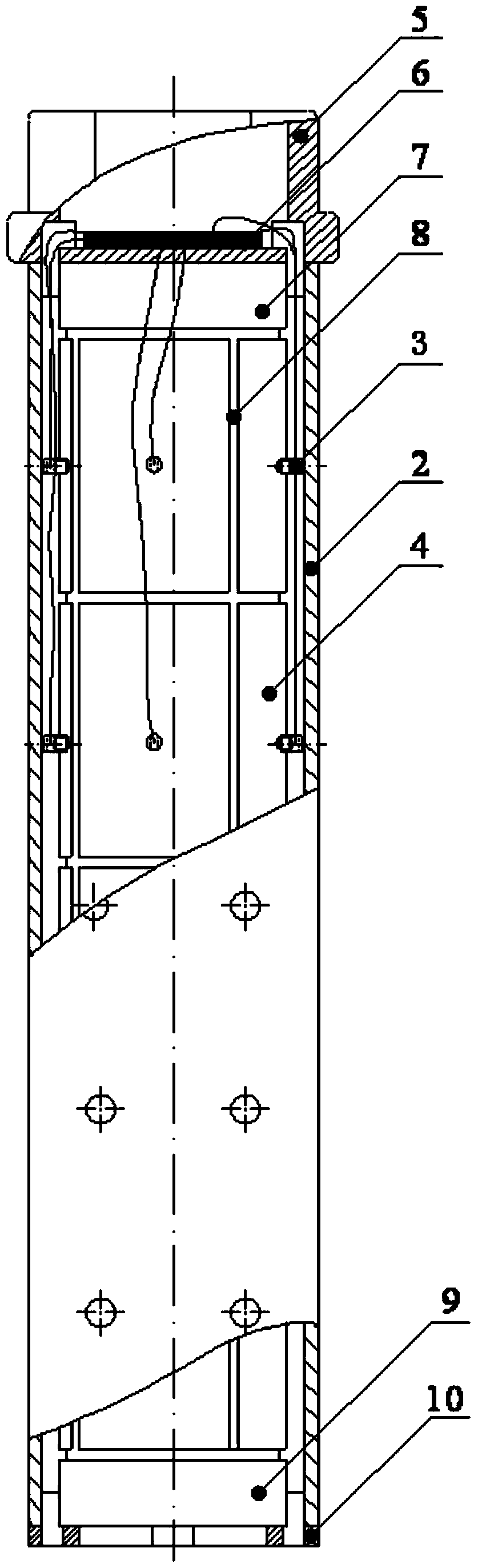

[0018] Such as figure 1 As shown, the new capacitive liquid level sensor is based on the principle of calculated capacitance, which is a new theorem of electrostatics proved by D.G.Lampard and A.M.Thompsion from Australia in 1956. It points out that when an infinitely long conductive cylinder with an arbitrary cross section is divided into four parts by infinitely small gaps at a, b, c, and d, the capacitance C between ab and cd 1 Capacitance C between ad and bc 2 Satisfy:

[0019] 2 - C 1 C 0 + 2 - C 2 C 0 = 1

[0020] where C 0 =(ε 0 ε r ln2) / π is a constant, ε 0 is the vacuum permitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com