Experimental device and method of assessing dielectric barrier discharge plasma flat plate turbulent drag reduction

A technology of dielectric barrier discharge and plasma, applied in the field of aerospace, to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

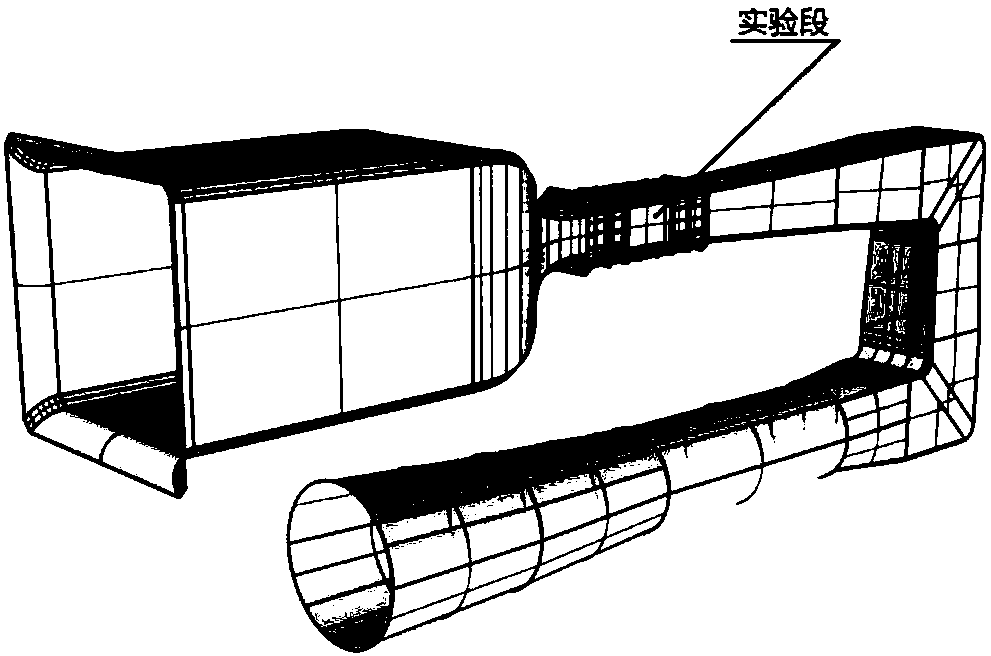

[0027] Such as figure 1 As shown, the experiment was carried out in a low-turbulence silent wind tunnel. The experimental section was 1.2mX1.2m (WXH), and the length was 3.5m (L). There were windows on both sides and the top for optical instruments. The wind speed was set to 15m / s, along the negative x direction.

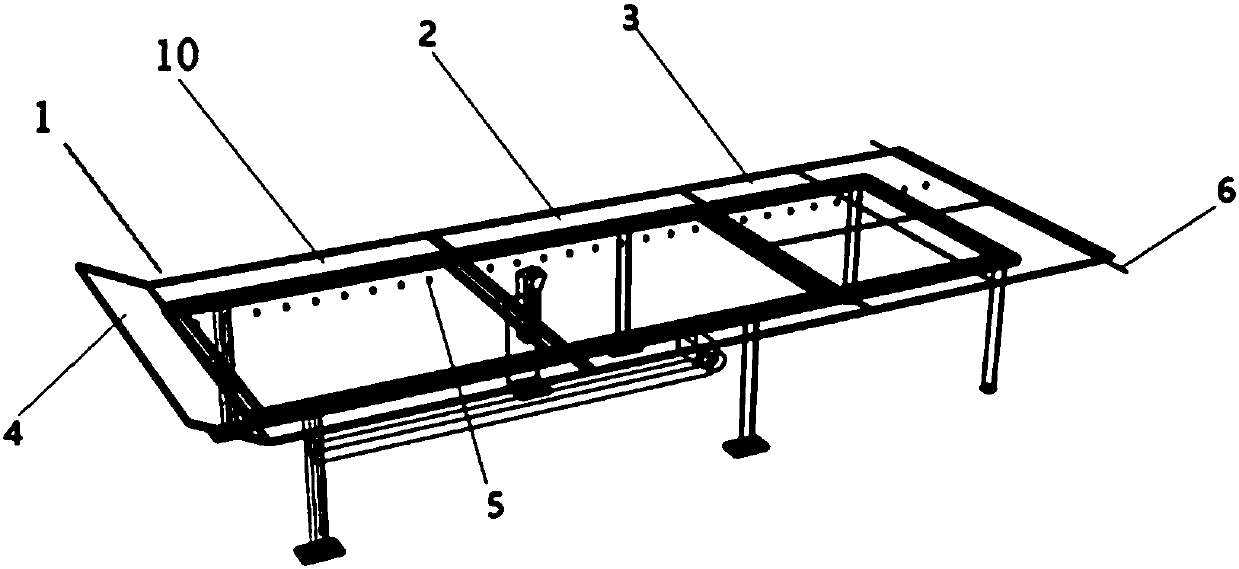

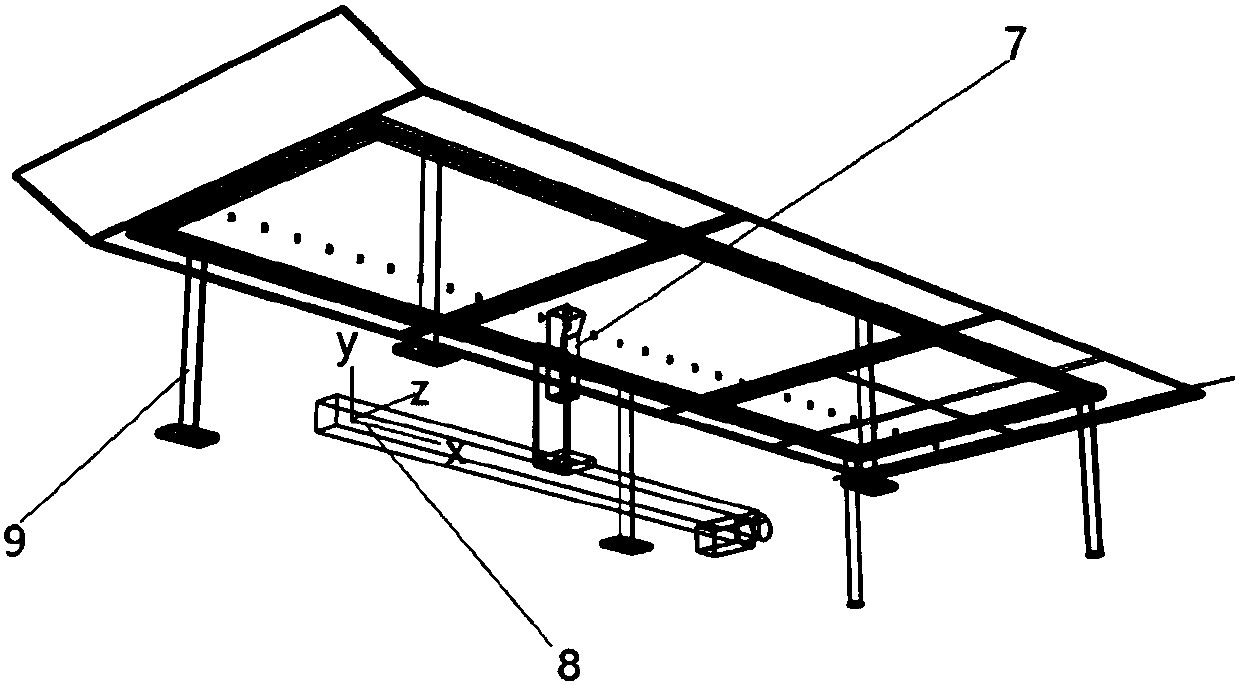

[0028] Such as figure 2 , 3 As shown, the zero pressure gradient plate 1 is built, which is composed of three 1mX0.8mX1cm acrylic horizontal plates 10, 2, 3 spliced by the fixed bracket 9, and the tail plate 4 is a 1mX0.2m acrylic plate relying on the fixed bracket and telescopic adjustment The rod is fixed, and the adjusting rod can be stretched and retracted as required, so as to adjust the angle of the tail plate. There is a side pressure hole 5 on the plate, which is connected to the rubber tube of the pressure measuring valve. The pressure measuring valve is placed outside the wind tunnel, and is connected to the plate by the rubber tube through the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com