Thermal reaction caps for enhanced decomposition combustion of alcohol-based fuels

A technology of thermal reaction cover and alcohol-based fuel, which is applied in the directions of burners, lighting and heating equipment, etc., can solve the problems such as the temperature drop of the furnace chamber, the failure to decompose the alcohol-based fuel in time, the reduction of the combustion rate and heat utilization rate of the alcohol-based fuel, etc. Reasonable flame distribution and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

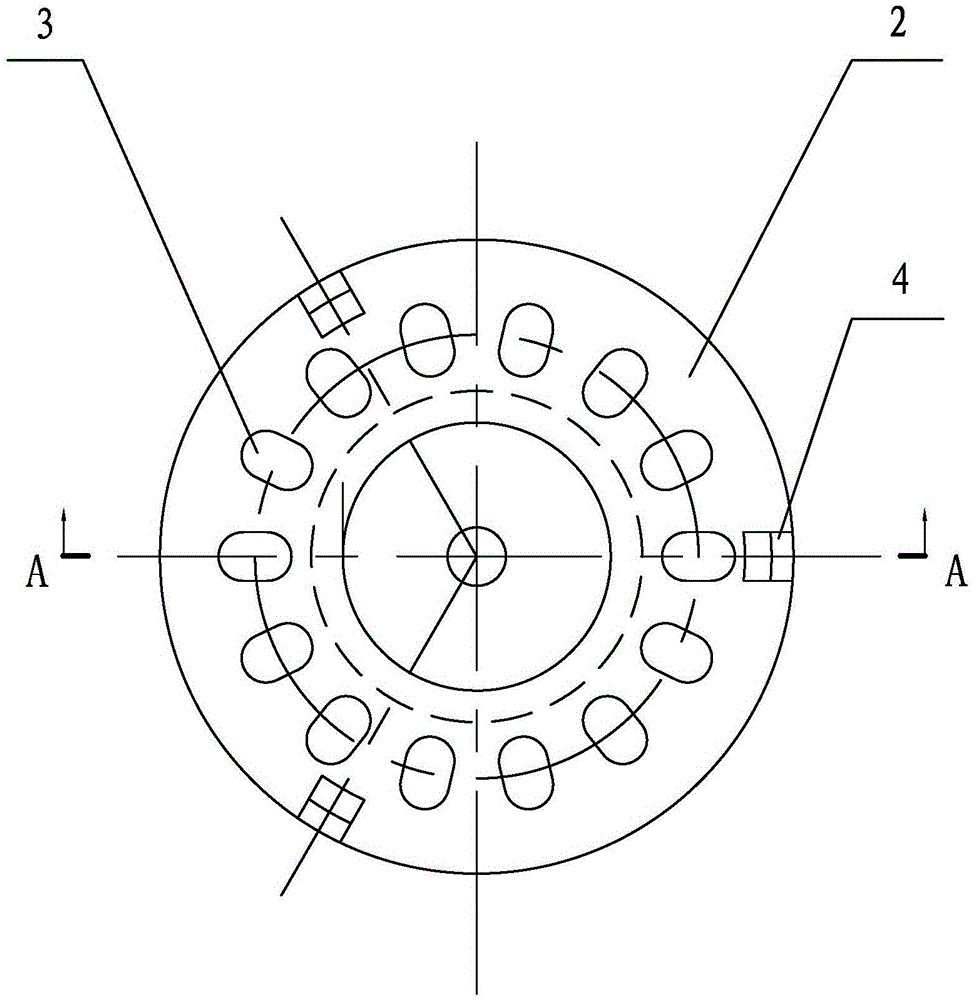

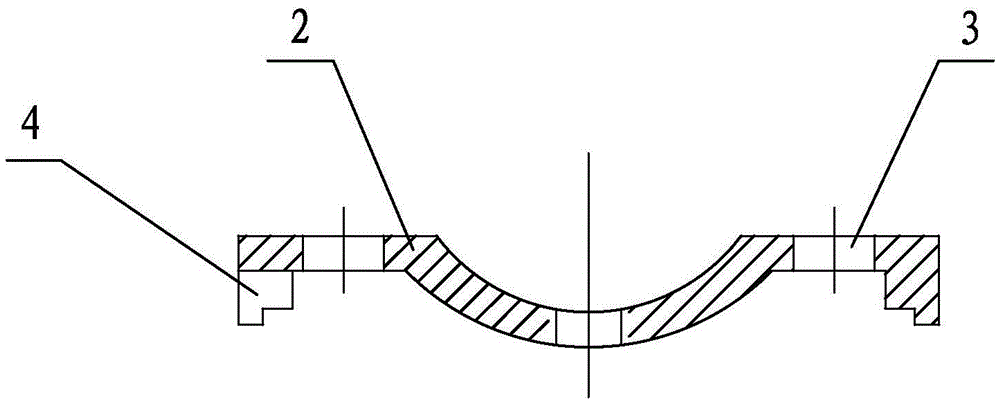

[0022] The heat reaction cover for improving the decomposition and combustion of alcohol-based fuels in the present invention is a cover body 2 formed by casting stainless steel. The cover body 2 is divided into two parts, namely the outer ring body and the concave sphere in the middle. The cloth is provided with flame holes 3, and the quantity of the flame holes 3 can be selected between 10 and 20 according to needs, and the shape of the flame holes 3 can be selected from round holes, or oval holes, or square holes, or kidney holes, or A triangular hole, a through hole is opened in the center of the concave sphere; three legs 4 are evenly distributed on the bottom of the ring body, as shown in Fig. 1(a) and Fig. 1(b).

[0023] Concrete application of the present invention:

[0024] The cover 2 is directly clamped on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com