Bearing type universal chain

A chain and bearing technology, applied in the chain field, can solve the problems of narrow application range, huge transmission system, transmission of motion in the same plane, etc., to achieve the effect of load-bearing transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

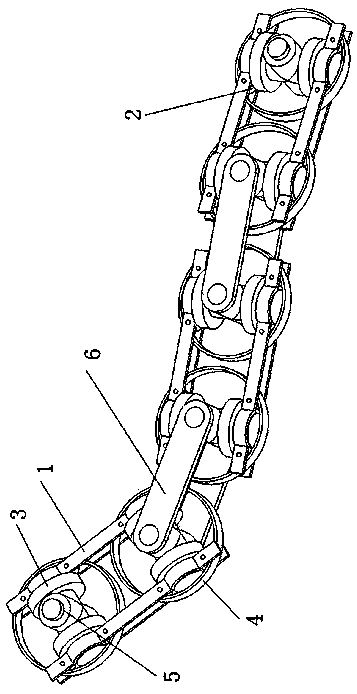

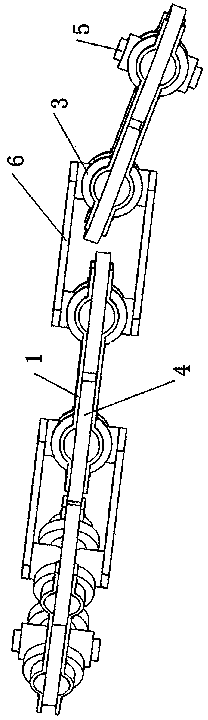

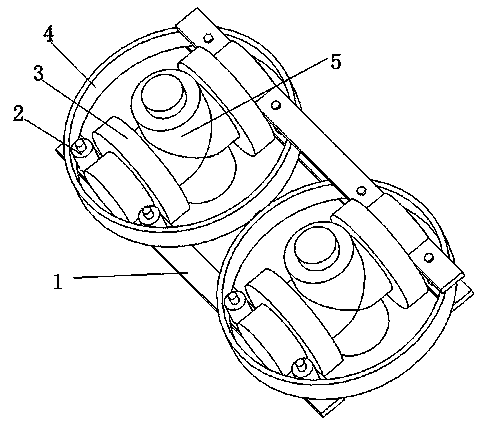

[0018] The invention discloses a bearing-type universal chain, the principle of which is to use the basic structure of the cross universal joint to realize the relative rotation of the cross shaft in the unit rail section in the vertical plane, and complete the vertical movement of two adjacent unit rail sections. Relative rotation in the plane, at the same time, two adjacent unit rail sections can rotate relatively in the horizontal plane, and finally solve the problem that the existing chain cannot be transmitted in multiple directions in three-dimensional space, and its specific structure includes at least two unit rail sections that can rotate relatively And the cross shaft connecting piece 6 used to connect the adjacent unit rail sections, the unit rail section includes two sets of running gear and the cross shaft frame 1 connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com