Transmission device with stepless speed regulating function

A transmission device, stepless speed regulation technology, applied in the directions of transportation and packaging, conveyors, fluid clutches, etc., can solve the problem of increasing the construction cost of equipment foundation, increasing the amount of roadway engineering, and increasing the space occupied by the drive part of the belt conveyor. Large and other problems, to achieve the effect of saving space, reducing volume and footprint, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

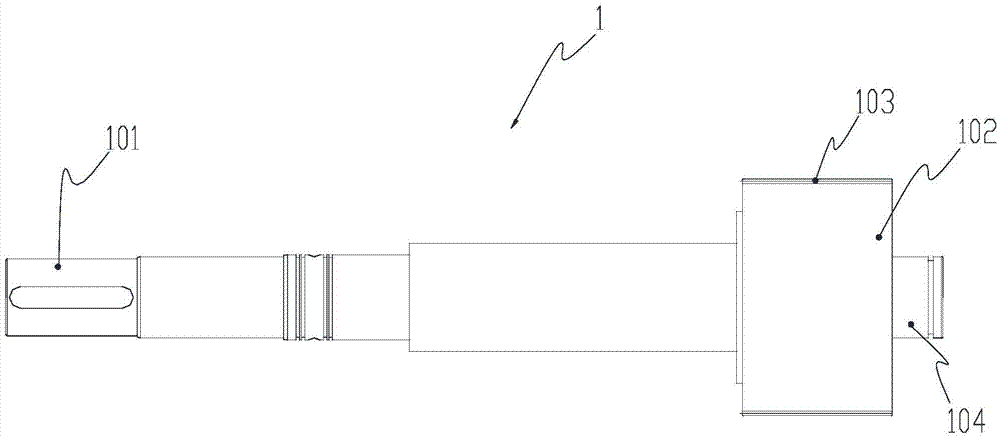

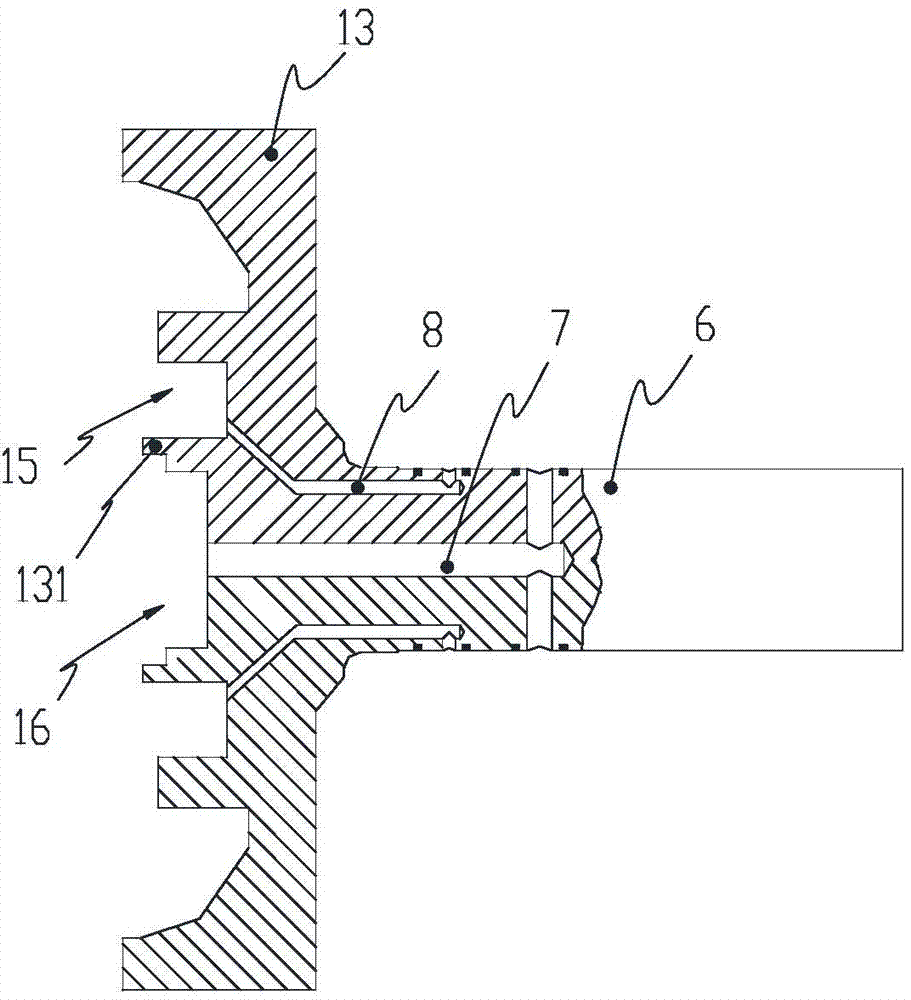

[0023] to combine Figure 1 to Figure 6 , a transmission device with stepless speed regulation function, including a drum 11 , a power input shaft 1 and a drum end shaft 6 . The outer end 101 of the above-mentioned power input shaft is located on one side of the drum, and the inner end 102 of the power input shaft extends into the inner cavity of the drum until it is close to the other side of the drum. The power input shaft is installed on the first drum through the end cover bearing 3 and the sealing ring. On the end cover 12, the power input shaft and the first end cover of the drum are in a dynamic sealing connection, the first end cover of the drum is fixed on one side of the drum, and the first end cover of the drum and the drum are in a sealed connection. The above-mentioned drum end shaft is fixed on the other side of the drum through the second end cover 13 of the drum. The second end cover of the drum and the drum are in a sealed connection. The end shaft 6 of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com