A combination drill bit combining a pdc drill bit and a roller cone bit for rock breaking

A technology of roller cone bit and combined drill bit, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and production, etc., which can solve the problems of low mechanical penetration rate of the drill bit, low rock breaking efficiency, and crushing, so as to achieve good working indicators and improve rock breaking efficiency , to ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

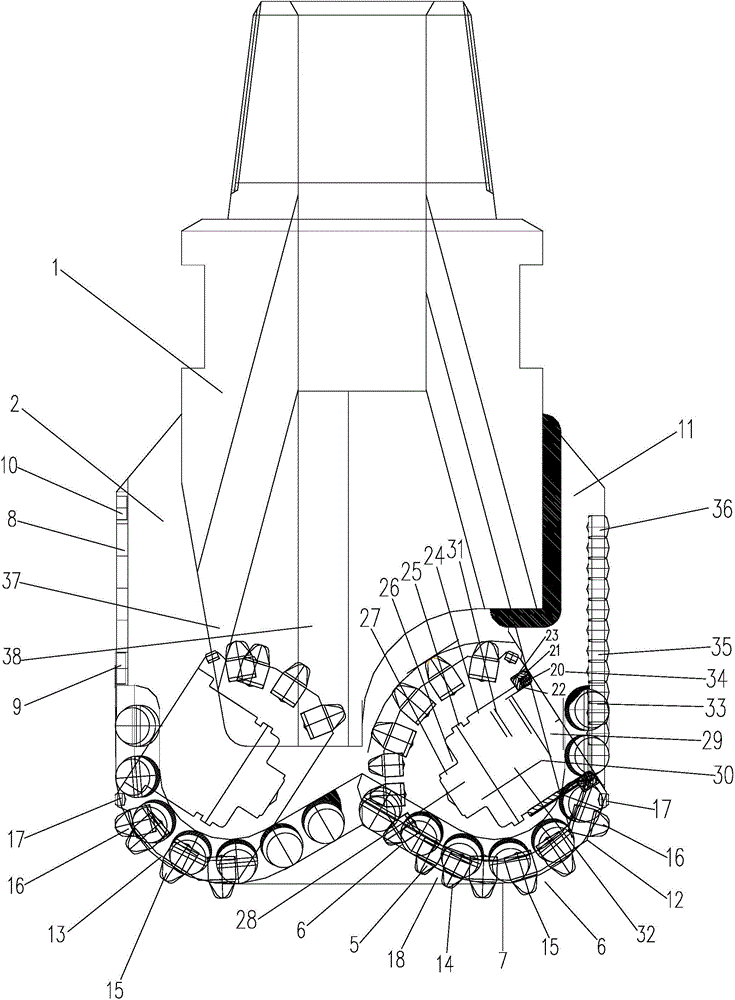

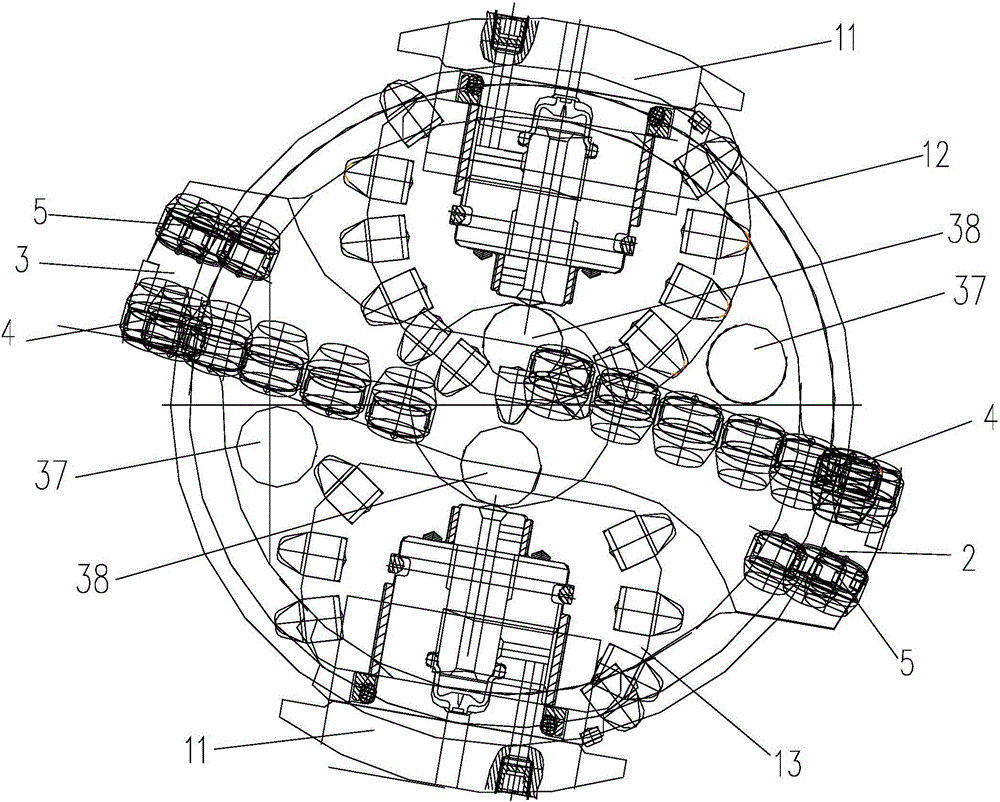

[0017] Such as figure 1 , figure 2 Shown, a kind of combination drill bit of PDC drill bit and roller cone bit combined rock breaking, comprises the PDC drill bit and roller cone bit that are connected to each other. The PDC drill bit includes a round steel body 1, and several blade groups and grooves are milled on the side of the round steel body 1. Each set of blades includes one blade 2 and two blades 3, one blade 2 and two blades 3 are in-line conjoined blades. The roller cone bit includes several tooth palms 11, and the tooth palms 11 are installed in the groove , and the bottom of the tooth palm 11 is provided with a gear set, and the gear set and the blade set are in one-to-one correspondence. Each set of cones includes a cone 12 and a second cone 13, and the outer sides of the first cone 12 and the second cone 13 respectively form a cone cone crushing surface 18 and a cone arc crushing surface 19. The round steel main body 1 is provided with a roller cone bit oil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com