Textile cleaning device

A technology for cleaning devices and handles, used in textiles, textiles, papermaking, knitting, etc., can solve the problems of impurity that cannot be removed and inconvenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

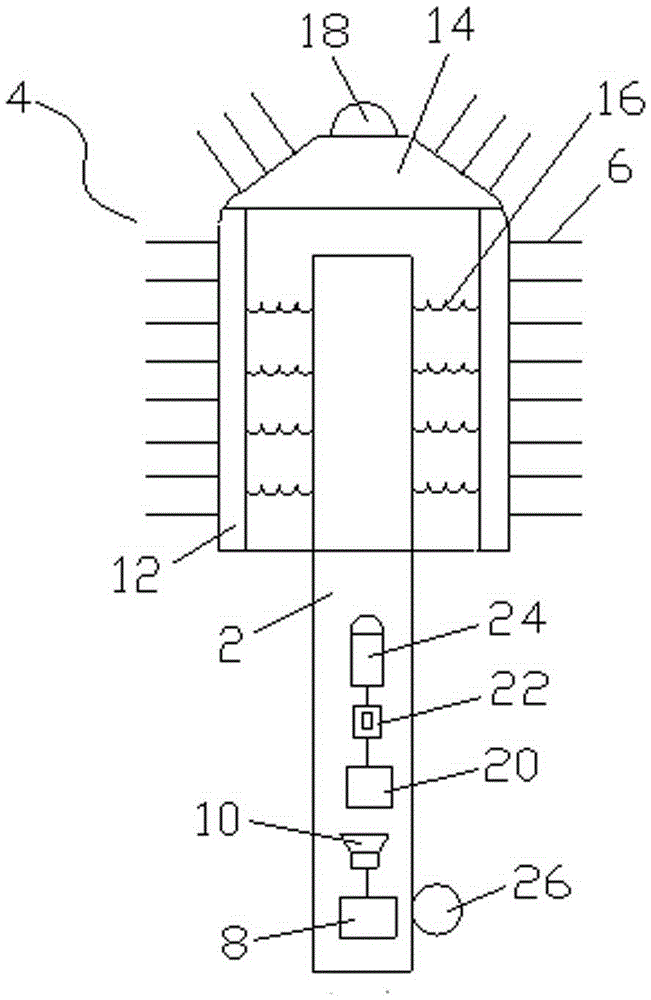

[0013] The present invention will now be described in further detail with reference to the drawings and embodiments. These drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, and therefore only show the constitutions related to the present invention.

[0014] Such as figure 1 As shown, a textile cleaning device includes a handle 2, a brush head 4 mounted on the handle 2, and the brush head 4 includes a bristle body and bristles 6 provided on the bristle body. The handle 2 is provided with a controller 8 and a control The bristles of the alarm 10 connected to the device 8 include a square brush body 12 and a cone-shaped brush body 14. The square brush body 12 has a large area, which enables a wide cleaning range and improves cleaning efficiency. The cone-shaped brush body 14 is easy to extend into the brush to be cleaned. In the part, the arc transition between the square brush body 12 and the cone-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com