Moving bed biomass pyrolysis equipment

A biomass pyrolysis and moving bed technology, which is applied in the field of biomass energy utilization and conversion, can solve the problems of lowering the temperature of the fluidized bed, difficulty, and insufficient pyrolysis of biomass raw materials, and achieves large processing capacity and drying efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

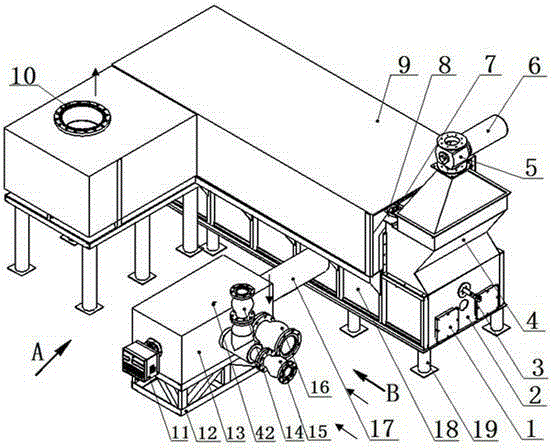

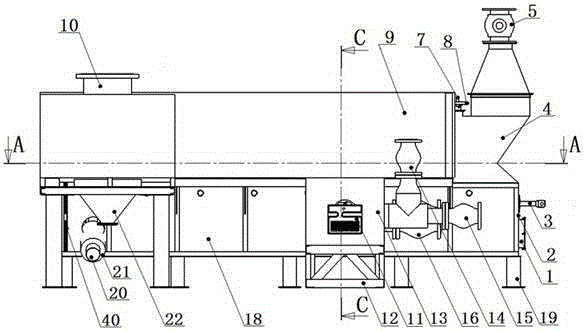

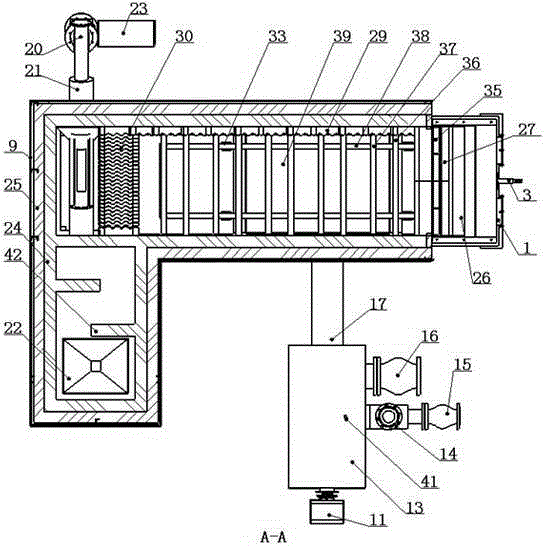

[0041] Such as figure 1 , 2 . As shown in 3: the moving bed biomass pyrolysis equipment includes a pyrolysis furnace body I, a feeding device II arranged at one end of the pyrolysis furnace body I, and a supply device connected to one side of the pyrolysis furnace body I through an air inlet passage 17. The wind device III and the discharge device IV arranged on the other side of the pyrolysis furnace body I.

[0042] When working, the material is sent to the pyrolysis furnace body I by the feeding device II after initial drying, and pyrolysis gas and solid residue are generated. The residue is discharged from the discharge device IV, and the gas is discharged from the pyrolysis gas outlet 10 and enters the condensation device. After condensation, the remaining pyrolysis gas is returned to the air supply device III to continue to be utilized.

[0043] Such as figure 2 , 3 , 5 and 6: the pyrolysis furnace body I includes a ventilation chamber A, a pyrolysis chamber B, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com