Carrier roller arrangement structure for horizontal bending belt conveyer

A technology for arranging structures and conveyors, applied in the direction of conveyors, conveyor objects, rollers, etc., can solve the problems of limited increase, reduced recovery rate, and poor transportation adaptability in the bending stage, so as to achieve small wear and crushing and reduce The effect of the loss of side coal and the reduction of the amount of chamber development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

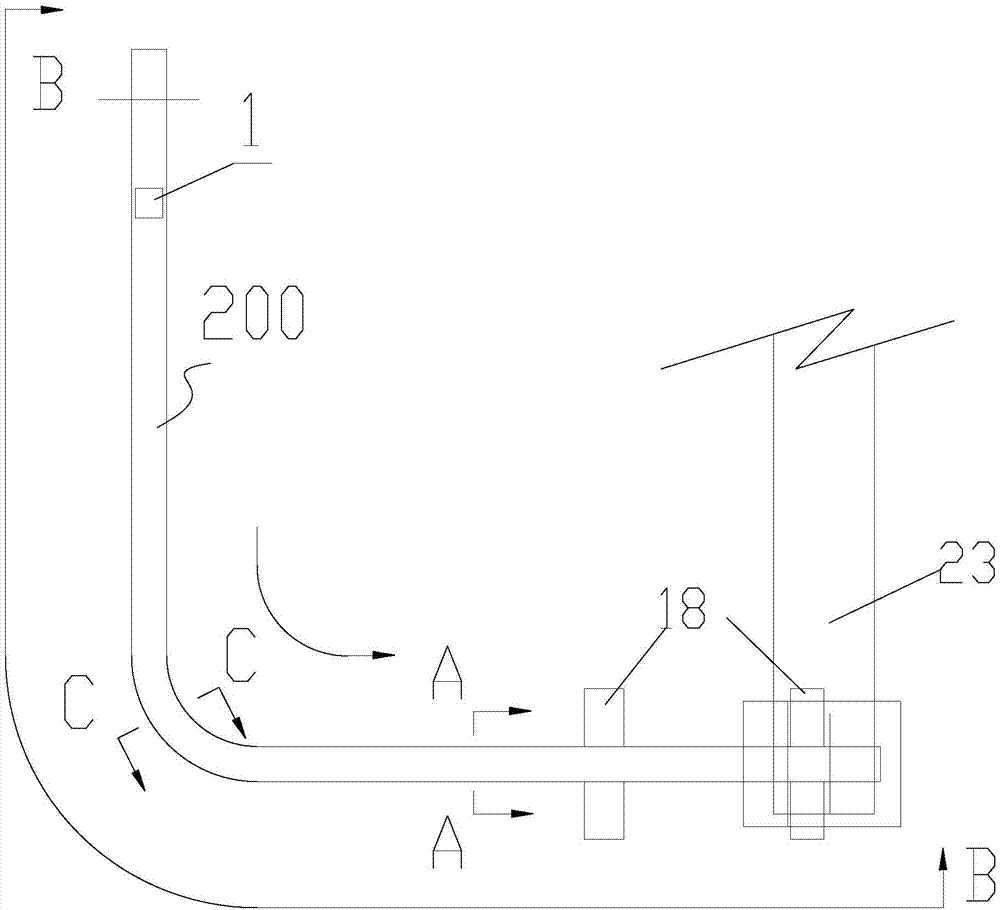

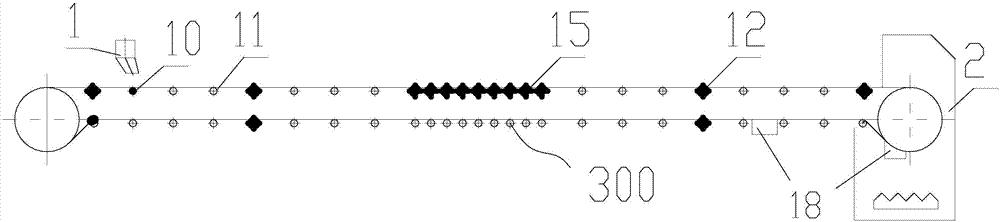

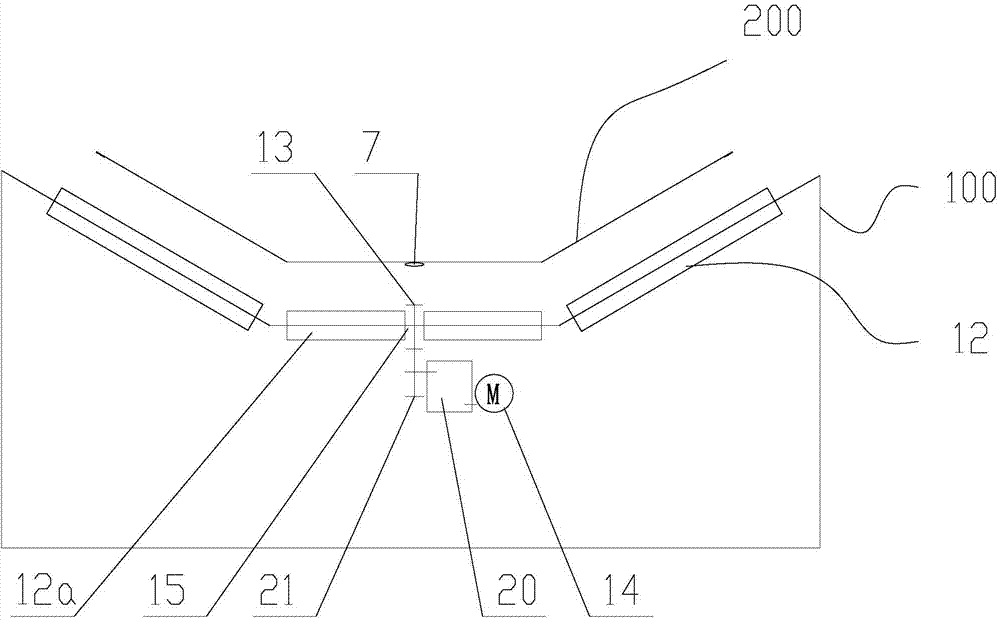

[0035] like figure 1 , figure 2 and image 3 As shown, an idler arrangement structure applied to a horizontal curved belt conveyor, the idler set 300 arranged under the conveyor belt includes a buffer idler 10, a flat idler 11 and a grooved idler 12, and the buffer idler The roller 10 is arranged below the charging device 1; the flat idler roller 11 and the grooved idler roller 12 are arranged at intervals.

[0036] The layout of the idler roller spacing should follow the principle that the deflection of the conveyor belt between the idler rollers should be as small as possible. The deflection value of the conveyor belt between the rollers generally does not exceed 2.5% of the spacing between the rollers. The distance between the upper rollers at the loading place should be smaller, the general distance is 200-300mm, and the distance between the lower ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com