Edge cutting machine for rubber ring

A technology of edge trimming machine and rubber ring, which is applied in metal processing and other directions, can solve the problems of infirmity, complex structure, inconvenient installation of inner ring cutter and outer ring cutter, etc., to improve efficiency, improve slicing quality, and facilitate installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

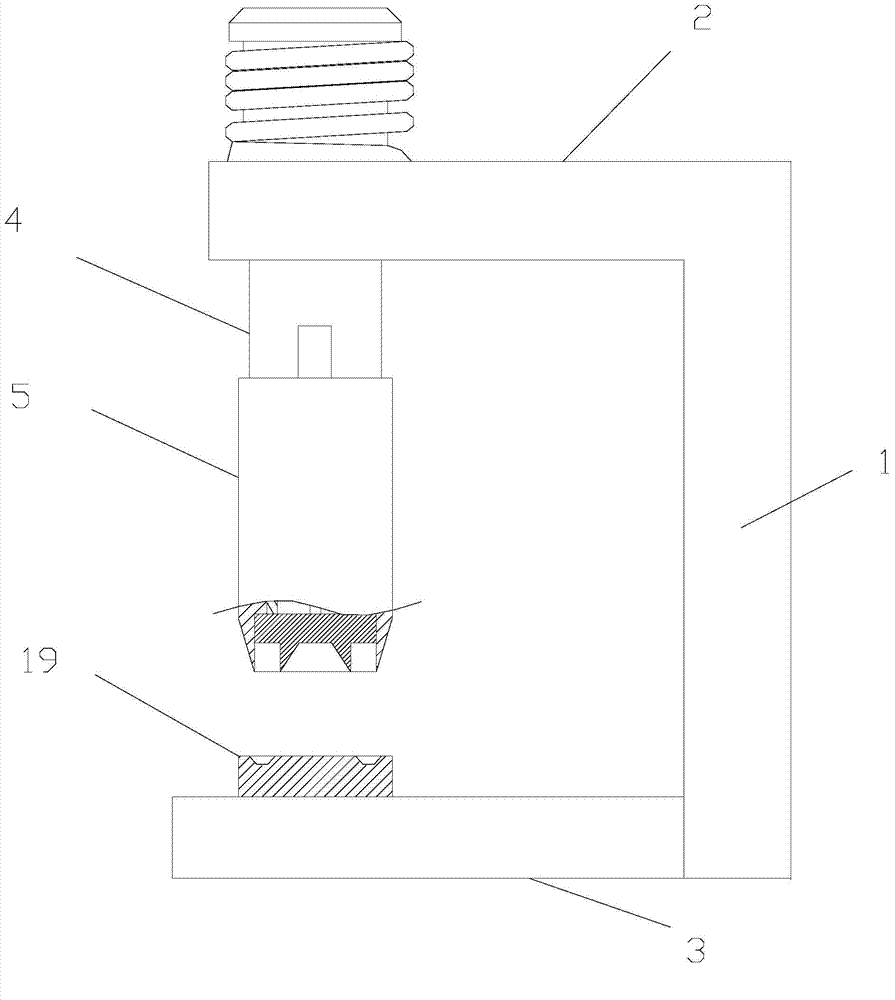

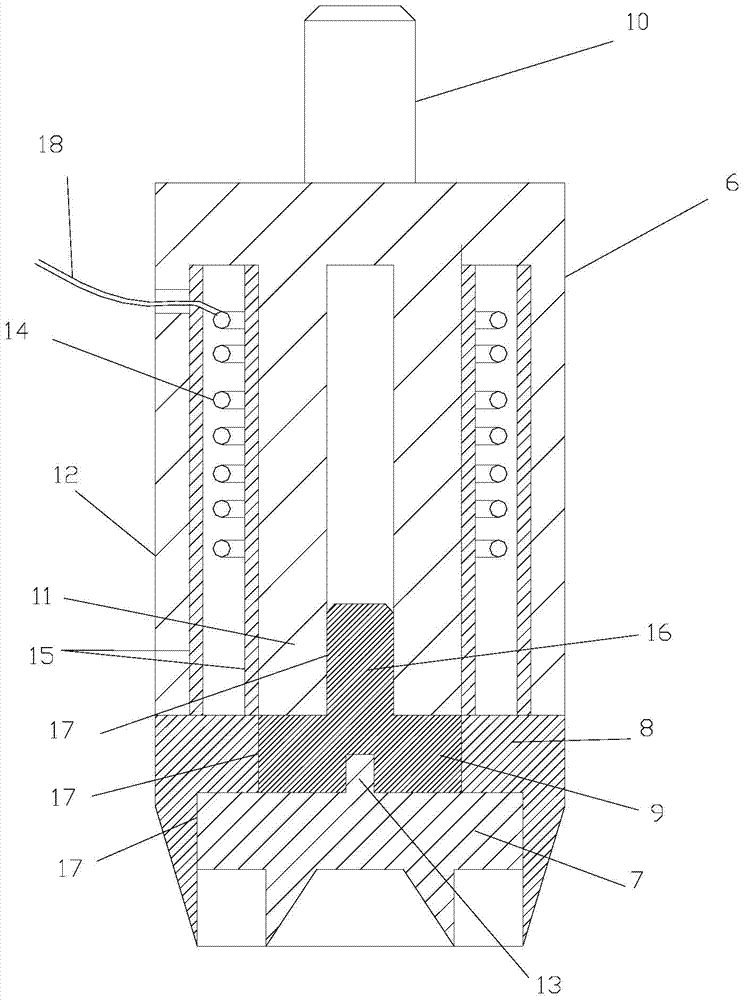

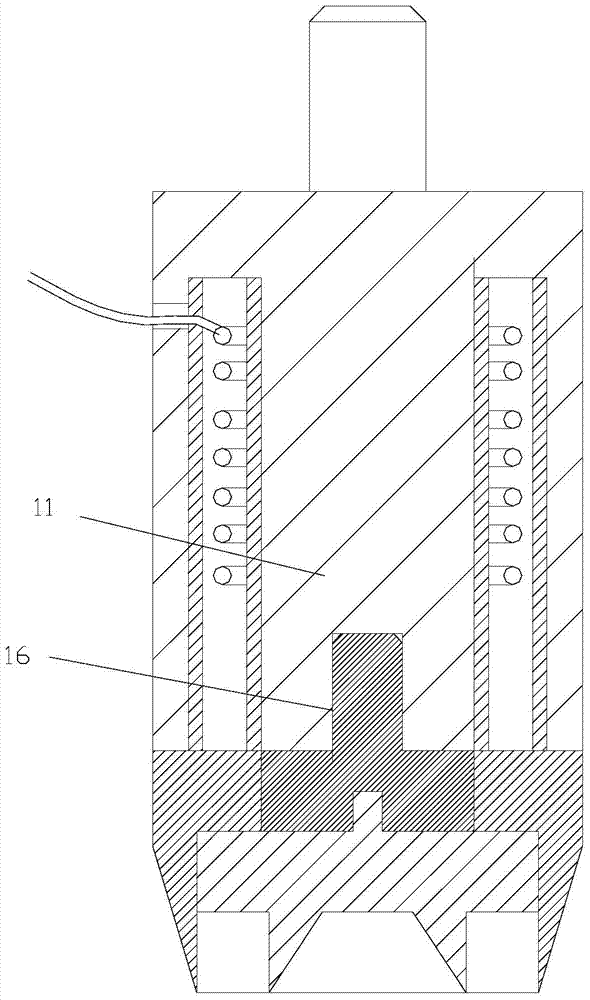

[0017] Such as figure 1 , 2 As shown, a rubber ring trimming machine described in this embodiment includes a frame 1, the frame 1 has an upper arm 2 and a base 3, the upper arm 2 is provided with a lifting mechanism 4, and the lower part of the lifting mechanism 4 is connected to an upper The punching head assembly 5 is provided with a mold 19 at the position below the upper punching head assembly 5 on the base 3, and the upper punching head assembly 5 is composed of a cylinder shell 6, an inner ring cutter 7, an outer ring cutter 8, The top of the shell 6 has a connecting head 10 (the connecting head 10 is installed on the bottom of the lifting mechanism 4 through a conventional mechanical connection method, and is generally connected by a key), and the lower part has a concentrically distributed inner tube body 11 and The outer tube body 12, the convex head 16 at the top of the convex plug 9 is inserted into the inner tube body 11 of the shell 6 and the convex head 16 forms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com