Hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel

An ultra-high-strength steel and composite forming technology, applied in the field of hot stamping, can solve the problems of poor trimming and punching quality, high cost, and low precision, and achieve good cross-section quality, low punching force, and reduced mold wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

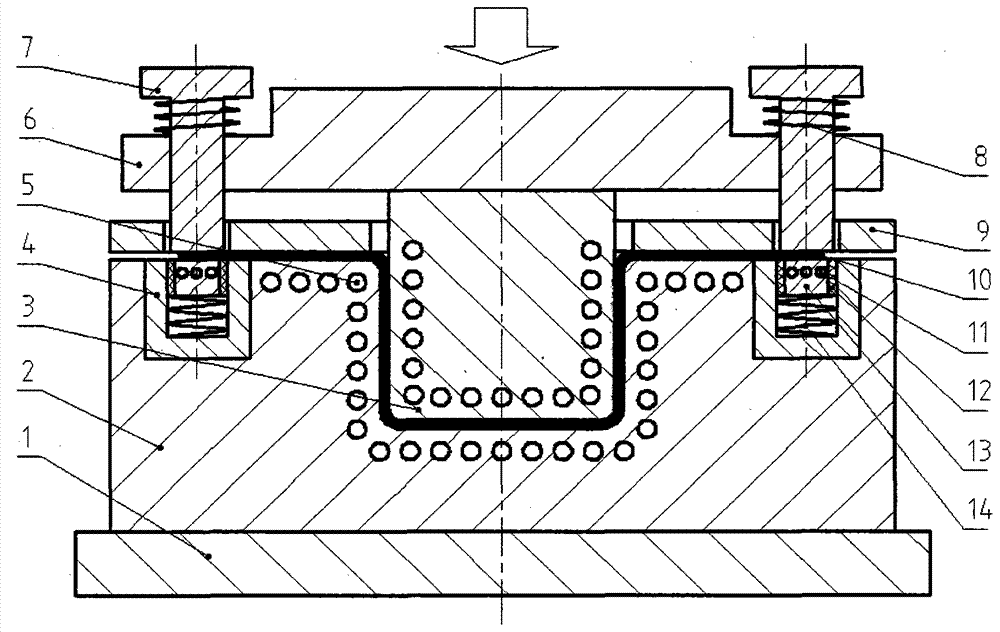

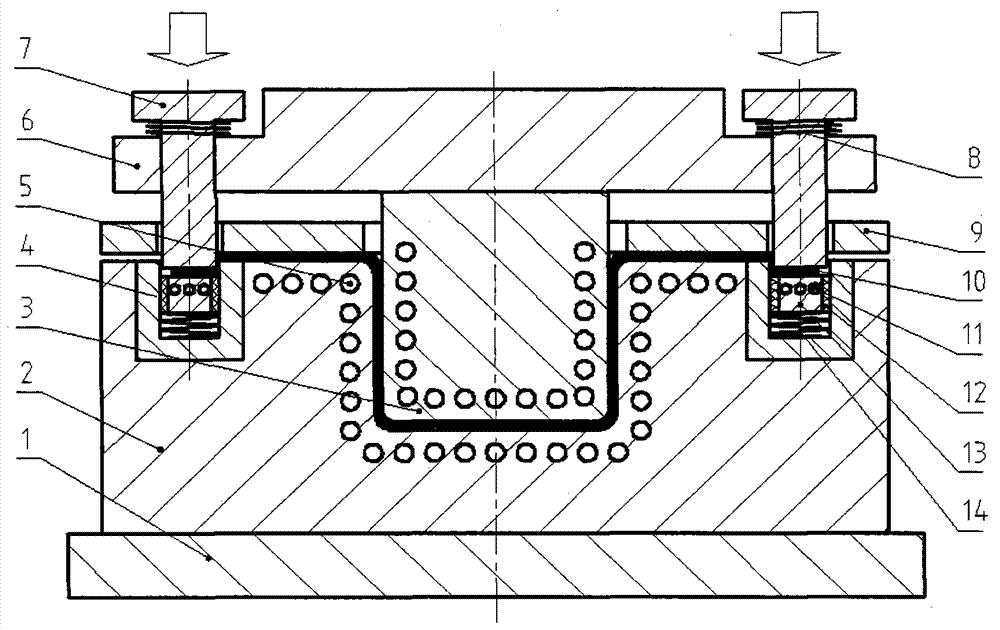

[0020] The content of the present invention and its specific implementation will be further described below by taking the hat forming and edge trimming process as an example, in conjunction with the accompanying drawings.

[0021] The hot stamping and warm stamping composite forming process for ultra-high strength steel of the present invention includes the following steps: placing the sheet material heated to an austenitized state in a composite mold → the press applies force to the stamping module, and the convex and concave molds are closed , to complete the hot stamping of the sheet → there is a cooling medium in the mold, and the sheet is quenched at the same time → the press moves the force to the punching module to realize the warm punching of the sheet → due to the action of the spring, the stamping part continues Cooling under pressure → Composite forming is completed, and the formed parts and waste are taken out.

[0022] The ultra-high-strength steel hot stamping an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com