Automatic tea shaping machine and shaping method thereof

A shaping machine and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems of low shaping efficiency, large manpower investment, and restrictions on the improvement of finished tea quality, and achieve low failure rate, small destructiveness, and low assembly technology requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

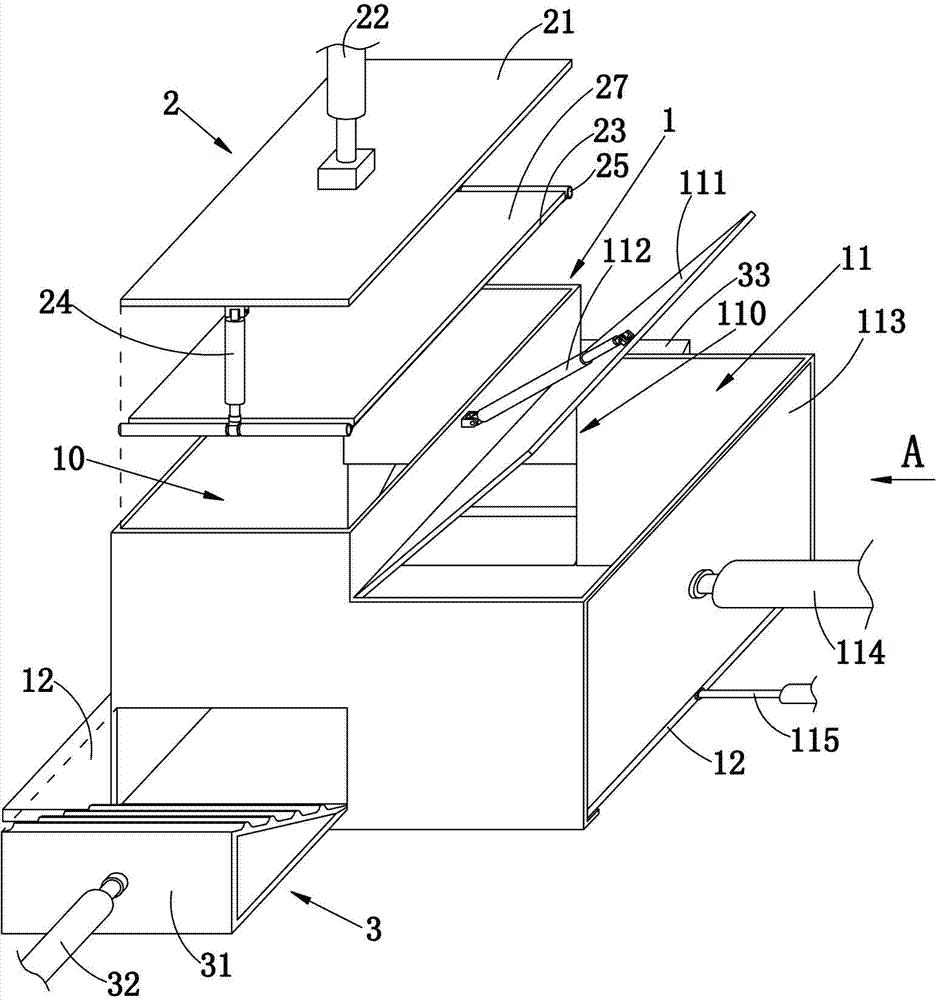

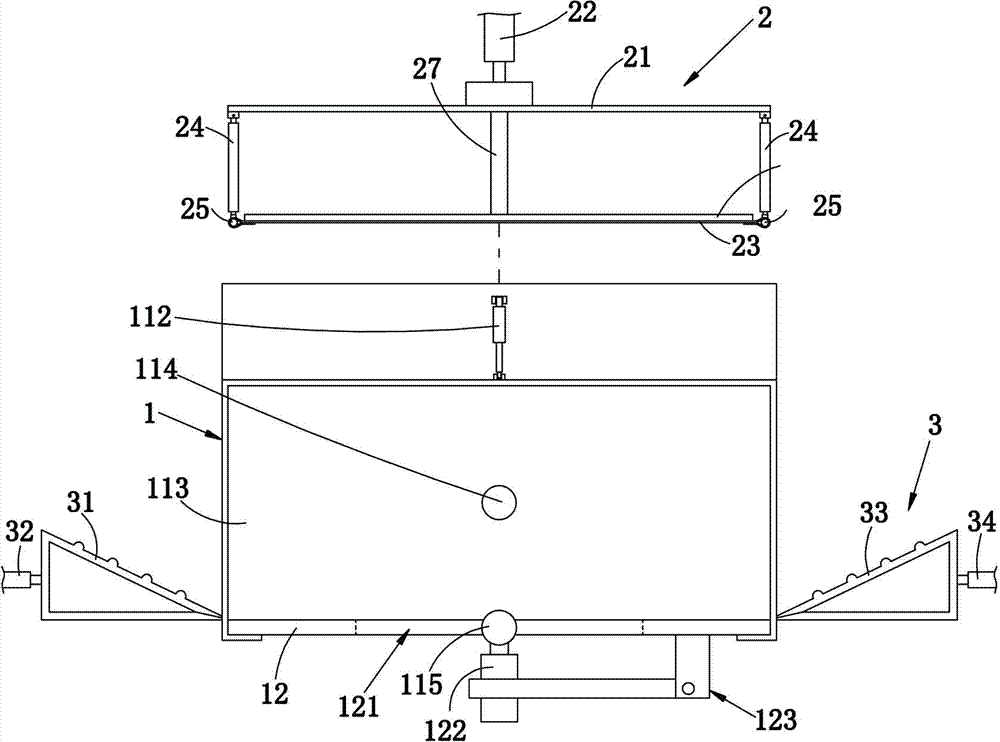

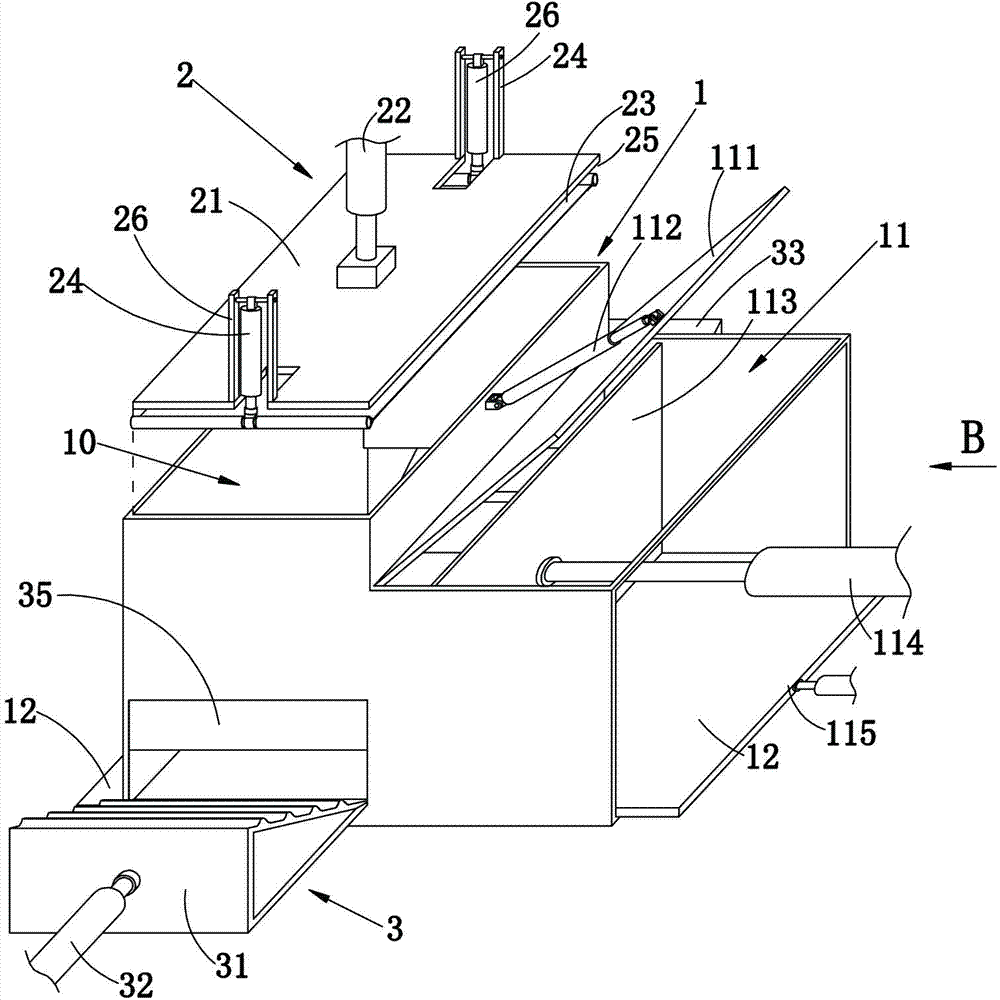

[0026] refer to figure 1 , image 3 , tea automatic shaping machine, which includes a main frame 1, a tea pressing mechanism 2, a wedge frame mechanism 3 and a microcomputer control device, the microcomputer control device is used to control the orderly action of each structure of the shaping machine.

[0027] Continue to refer to figure 1 , image 3 , main frame 1 is provided with shaping chamber 10, advances tea chamber 11 and base plate 12, and the top of this shaping chamber 10 and enters tea chamber 11 is opening structure, and its bottom is all covered by this base plate 12. More specifically, the tea inlet chamber 11 is provided with a tea outlet passage 110 , and the tea inlet chamber 11 communicates with the above-mentioned shaped chamber 10 through the tea outlet passage 110 . The top of the tea inlet bin 11 is provided with a bin door 111, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com