Adhesive tape and masker

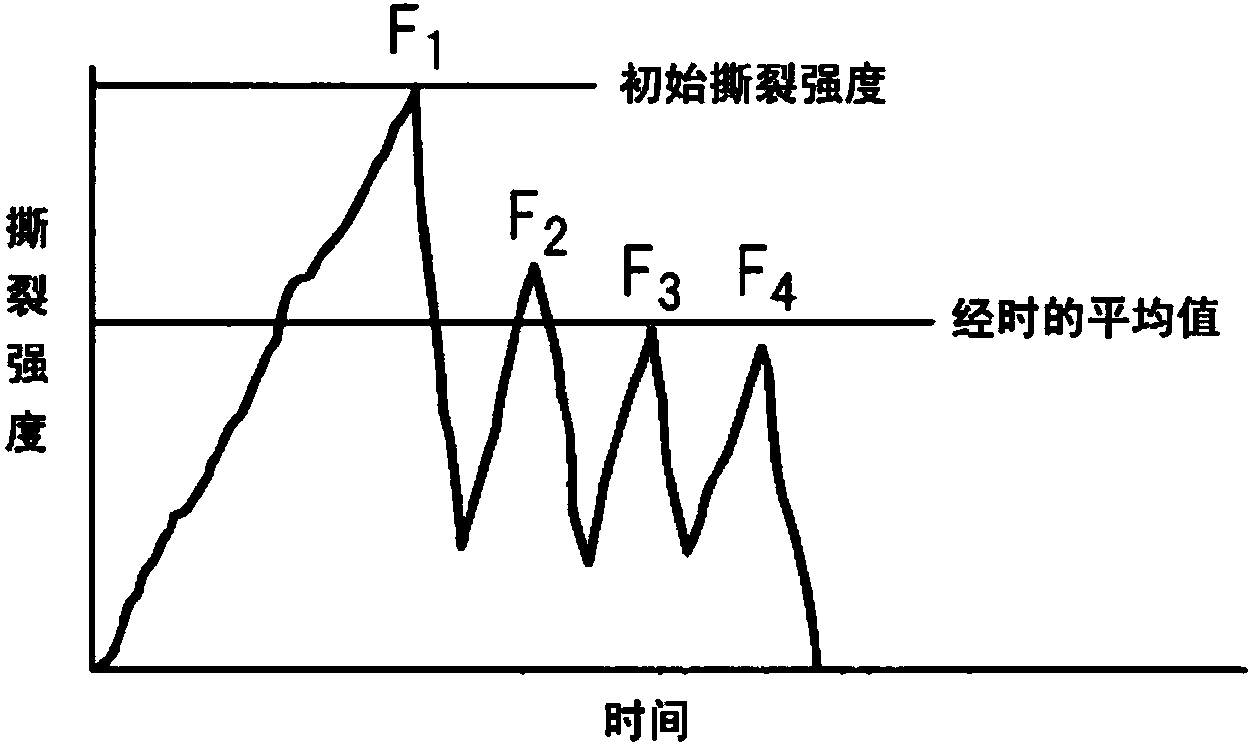

A technology of adhesive tapes and adhesives, which is applied in the direction of film/sheet adhesives, adhesives, transportation and packaging, etc. It can solve the problems of low coating and no stickiness, etc., and achieve excellent water resistance and followability Excellent, hand-tearable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

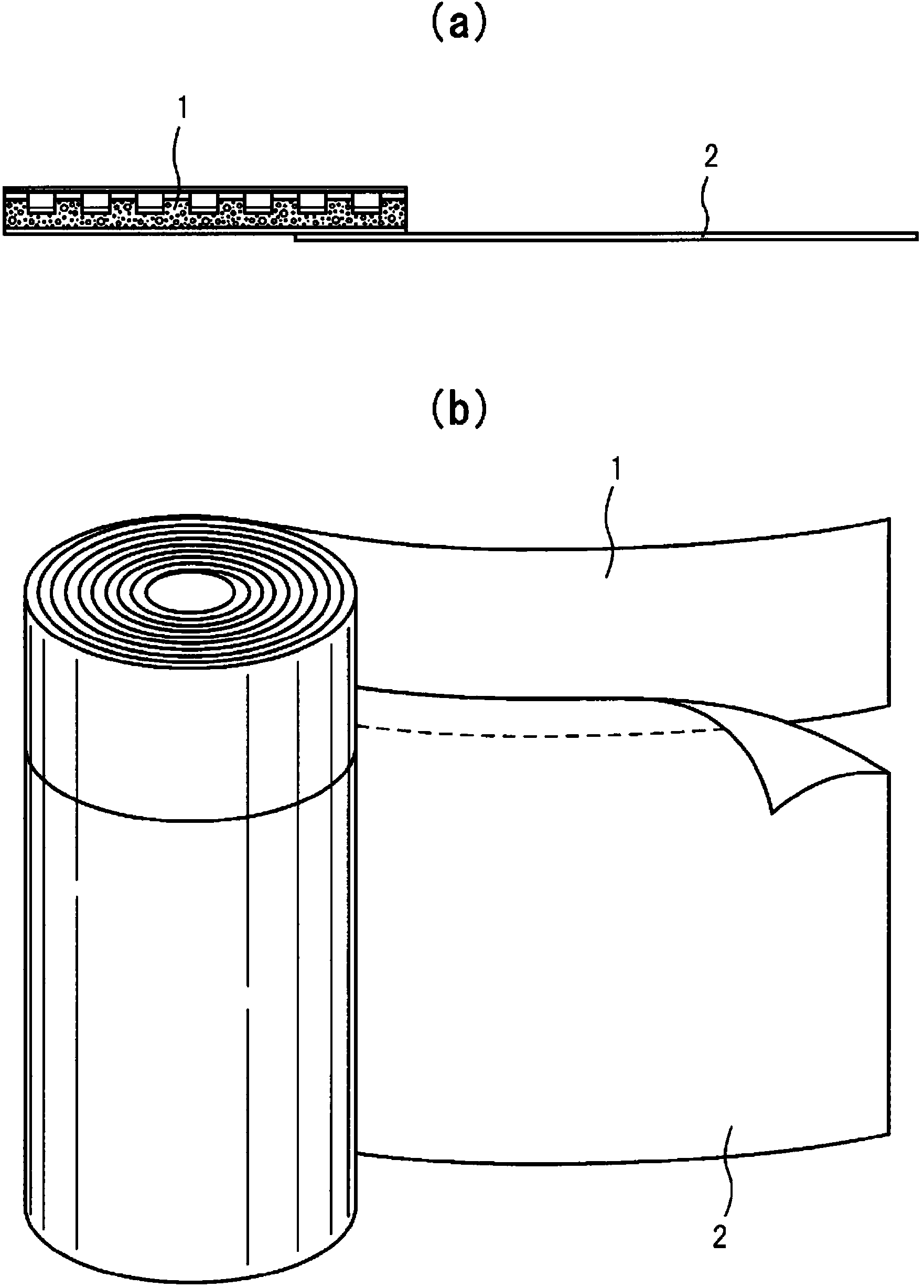

[0123] (Production of adhesive tape base sheet)

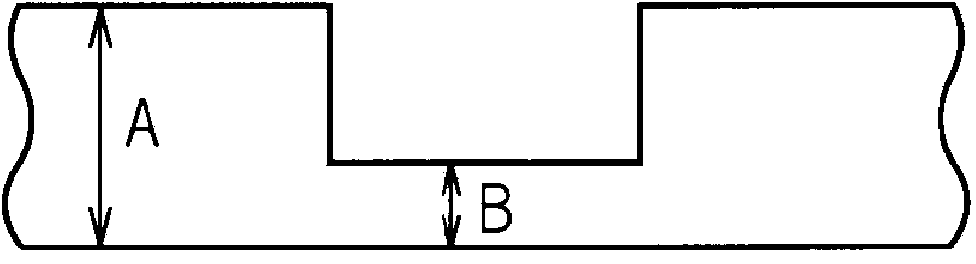

[0124] A polypropylene long-fiber web formed by a single layer with a fiber diameter of 18 μm obtained by the spunbonding method was deposited on a web conveyor belt, and thermally compressed with a pair of embossing rolls to obtain a partial thermal compression ratio of 8%, Weight per unit area is 40g / m 2 , Polypropylene long-fiber non-woven fabric with a thickness of 310 μm. Next, calendering was carried out at a temperature of 80° C. and a linear pressure of 300 N / cm to make a thickness of 120 μm, and then linear embossing was carried out in the width direction of the tape at a temperature of 80° C. and a linear pressure of 300 N / cm ( After width 0.3mm x embossing interval 3mm), resin impregnation treatment was performed. In addition, the angle of linear embossing was 0.2 degrees with respect to the roll rotation axis. As the synthetic resin, water-based acrylic resin "NIKASOL FA-2555A" manufactured by Nippon Carbide Indu...

Embodiment 2

[0131] (Production of adhesive tape base sheet)

[0132] The fibers obtained by the spunbond method in the upper and lower layers have a diameter of 18 μm and a weight per unit area of 11 g / m 2 The polypropylene fiber non-woven fabric (S) and the two layers in the middle layer obtained by the melt-blown method have a fiber diameter of 4 μm and a weight per unit area of 1.5 g / m 2 The 4-layer laminated web (SMMS) of the polypropylene microfiber nonwoven fabric (M) was thermocompression-bonded to obtain a partial thermocompression bonding rate of 14% and a weight per unit area of 25g / m 2 , A multi-layer long-fiber nonwoven fabric with a thickness of 240 μm. Next, calendering was performed at a temperature of 20° C. and a linear pressure of 300 N / cm to have a thickness of 80 μm, and then linear embossing and resin impregnation were performed in the same manner as in Example 1. As the synthetic resin, use the same resin as in Example 1, and achieve 15 g / m by the amount of r...

Embodiment 3

[0137] (Production of adhesive tape base sheet)

[0138] On the side of the release agent-coated side of the adhesive tape base cloth b obtained in the same manner as in Example 2, the amount of coating after drying was 5 g / m 2 "NIPOL LX430" manufactured by Zeon Corporation having a glass transition temperature of 12° C. was applied in such a manner as to obtain a tape base sheet c.

[0139] (Coating of adhesives and release agents)

[0140] With the adhesive a same as embodiment 1 with 40g / m 2 Coated on the adhesive coated surface of the above-mentioned adhesive tape base sheet c, on the release agent coated surface at 0.1g / m 2 The pressure-sensitive adhesive tape of the present invention was obtained by applying a release agent "Peeloil 1010 manufactured by Ichisha Yushi Co., Ltd.".

[0141] Table 1 shows the evaluation results of the obtained pressure-sensitive adhesive tape together with the characteristics of the nonwoven fabric, the base fabric for tape, and the tape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com