Organic electroluminescence apparatus and preparation method thereof

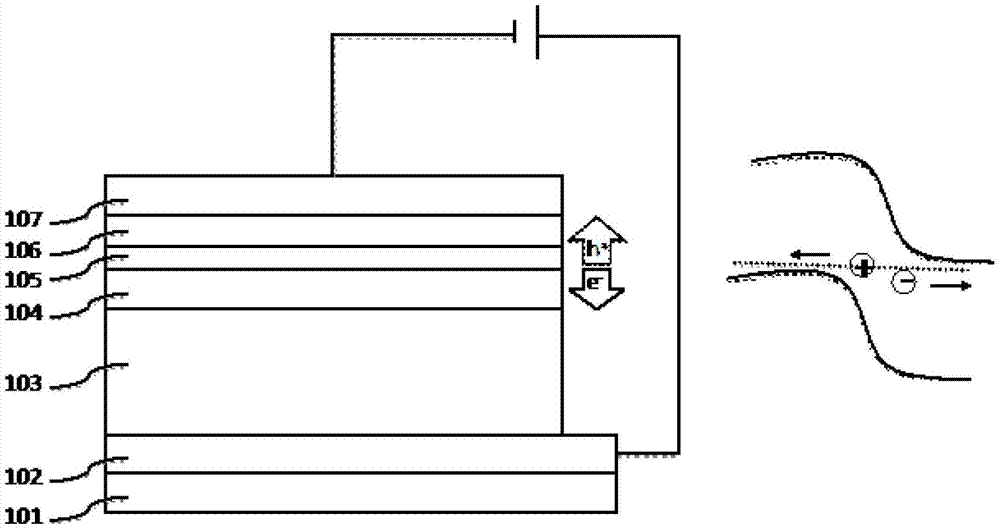

An electroluminescence device and electroluminescence technology, which are applied in the directions of organic light-emitting devices, organic light-emitting device structures, and organic light-emitting device parameters, etc. problem, to achieve high luminescence performance, improve the recombination probability and luminescence quantum efficiency, and improve the effect of electron injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

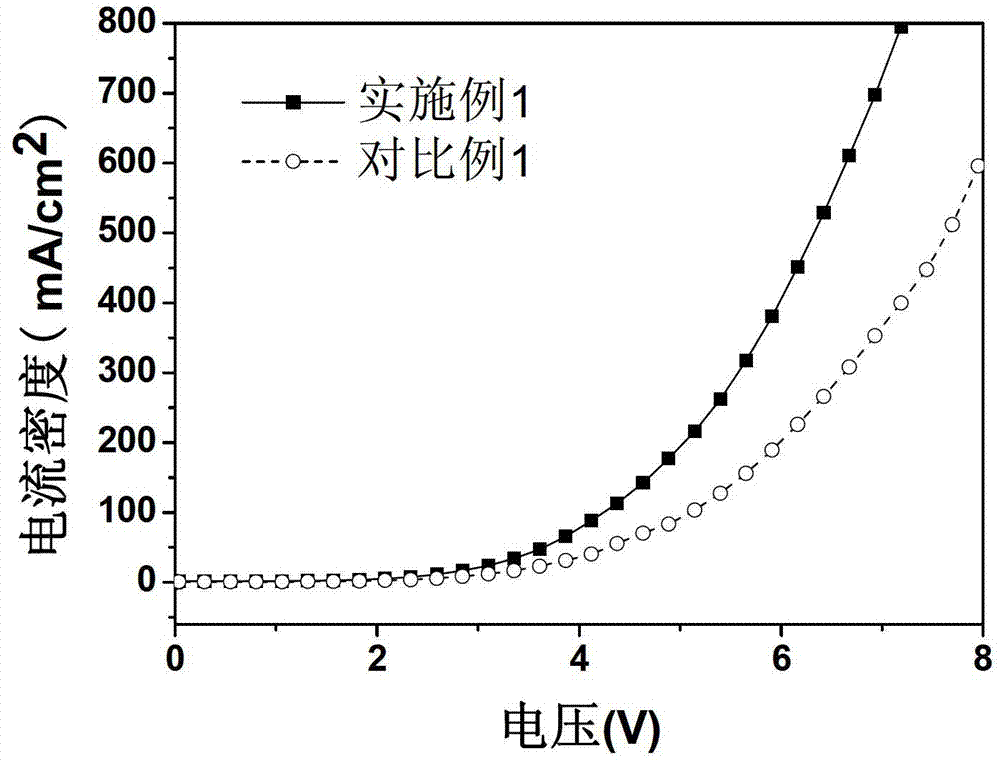

Embodiment 1

[0081] A preparation method of an organic electroluminescence device, comprising the following steps:

[0082] The glass substrate was placed in deionized water containing detergent for ultrasonic cleaning, and after cleaning, treated with isopropanol and acetone in ultrasonic waves for 20 minutes, and then dried with nitrogen;

[0083] 1 x 10 in vacuum -4 In the vacuum coating system of Pa, an indium tin oxide (ITO) film was prepared by sputtering at a speed of 0.1 nm / s on the surface of the glass substrate as the anode;

[0084] Through thermal evaporation process, the vacuum degree is 1.0×10 -4 Under the conditions of Pa and speed of 0.02nm / s, F6-TNAP was doped into MeO-TPD according to the doping mass fraction of 5%, and the mixed material was formed. TPD and DCJTB were doped into Alq according to the doping mass fraction of 8%. 3 Hybrid materials, TPBi, Li formed in 2 CO 3 The hole transport layer, the electron blocking layer, the light emitting layer, the hole blocki...

Embodiment 2

[0089] A method for preparing an organic electroluminescent device, comprising the steps of:

[0090] Place the glass substrate in deionized water containing detergent for ultrasonic cleaning. After cleaning, use isopropanol and acetone in ultrasonic treatment for 20 minutes, and then blow dry with nitrogen;

[0091] At a vacuum of 1 × 10 -5 In Pa's vacuum coating system, a gallium zinc oxide film (GZO) is prepared as an anode by sputtering at a speed of 1nm / s on the surface of a glass substrate;

[0092] Through thermal evaporation process, in a vacuum of 1.0×10 -5 Under the conditions of Pa and speed 0.5nm / s, F2-HCNQ is sequentially evaporated to form a mixed material, TPD, Ir(ppy) doped into ZnPc according to the doping mass fraction of 10%. 3 The mixed material, BAlq, CsN formed by doping TCTA according to the doping mass fraction of 10% 3 According to the mixed material doped into PBD with a doping mass fraction of 15%, the hole transport layer, electron blocking layer...

Embodiment 3

[0096] A method for preparing an organic electroluminescent device, comprising the steps of:

[0097] Place the glass substrate in deionized water containing detergent for ultrasonic cleaning. After cleaning, use isopropanol and acetone in ultrasonic treatment for 20 minutes, and then blow dry with nitrogen;

[0098] In a vacuum of 1×10 -3 In Pa's vacuum coating system, aluminum zinc oxide film (AZO) is prepared as anode by sputtering at a speed of 0.5nm / s on the surface of the glass substrate;

[0099] Through thermal evaporation process, in a vacuum of 1.0×10 -3 Under the conditions of Pa and speed of 0.2nm / s, F4-TCNQ is sequentially evaporated to form a mixed material, TAPC, DPVBi, BAlq, Cs doped into CuPc according to the doping mass fraction of 2%. 2 CO 3 A hole transport layer, an electron blocking layer, a light-emitting layer, a hole blocking layer, and an electron transport layer were respectively prepared from the mixed materials formed by doping 5% doping mass fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com