Bar code mistake proofing managing system for motormeter production

A technology of management system and automobile instrument, which is applied in the field of barcode error prevention management system for the production of automobile instrument, can solve the problems that affect the pass rate of automobile instrument products and cannot supervise production, so as to improve supervision and management, reduce management manpower, and improve qualification rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

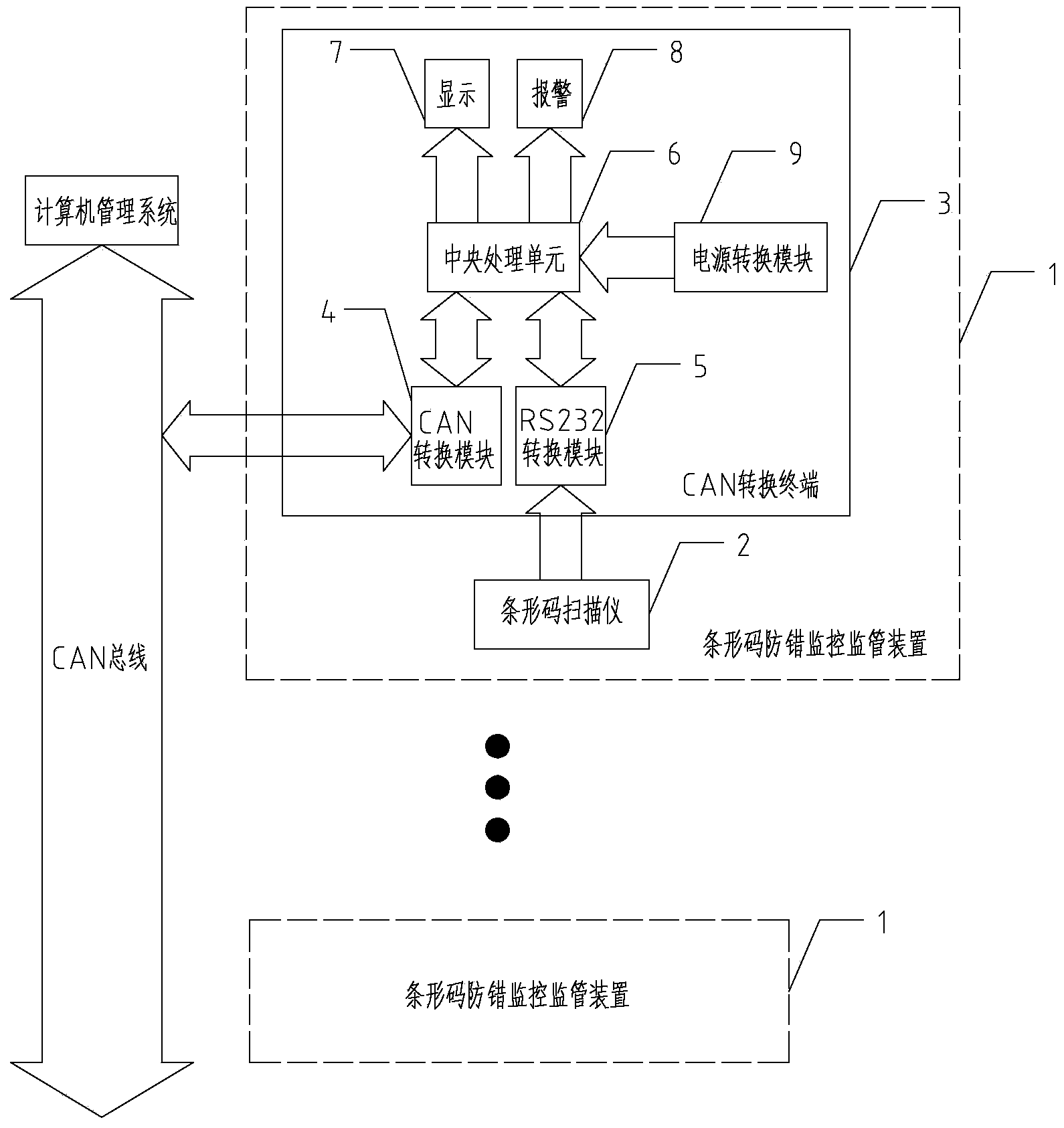

[0009] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the barcode error-proof management system for automobile instrument production described in this embodiment, the system includes a plurality of barcode error-proof monitoring and supervision devices 1, and a barcode error-proof monitoring and supervision device 1 is installed on each station, and each barcode error-proof monitoring and supervision device 1 The supervisory data signal end of anti-error monitoring supervision device 1 is all connected to the computer management system through CAN bus; Described each barcode anti-error monitoring supervision device 1 comprises bar code scanner 2 and CAN conversion terminal 3, and CAN conversion terminal 3 comprises CAN conversion module 4, RS232 conversion module 5, CPU6, display 7 and alarm 8;

[0010] The scan data signal output end of the barcode scanner 2 is connected to the scan data signal input end of the RS232 conversion ...

specific Embodiment approach 2

[0012] Specific implementation mode two: the following combination figure 1 This embodiment will be described. This embodiment will further describe Embodiment 1. The CAN conversion terminal 3 further includes a power conversion module 9 , and the power conversion module 9 supplies power to the CPU 6 of the CAN conversion terminal 3 .

specific Embodiment approach 3

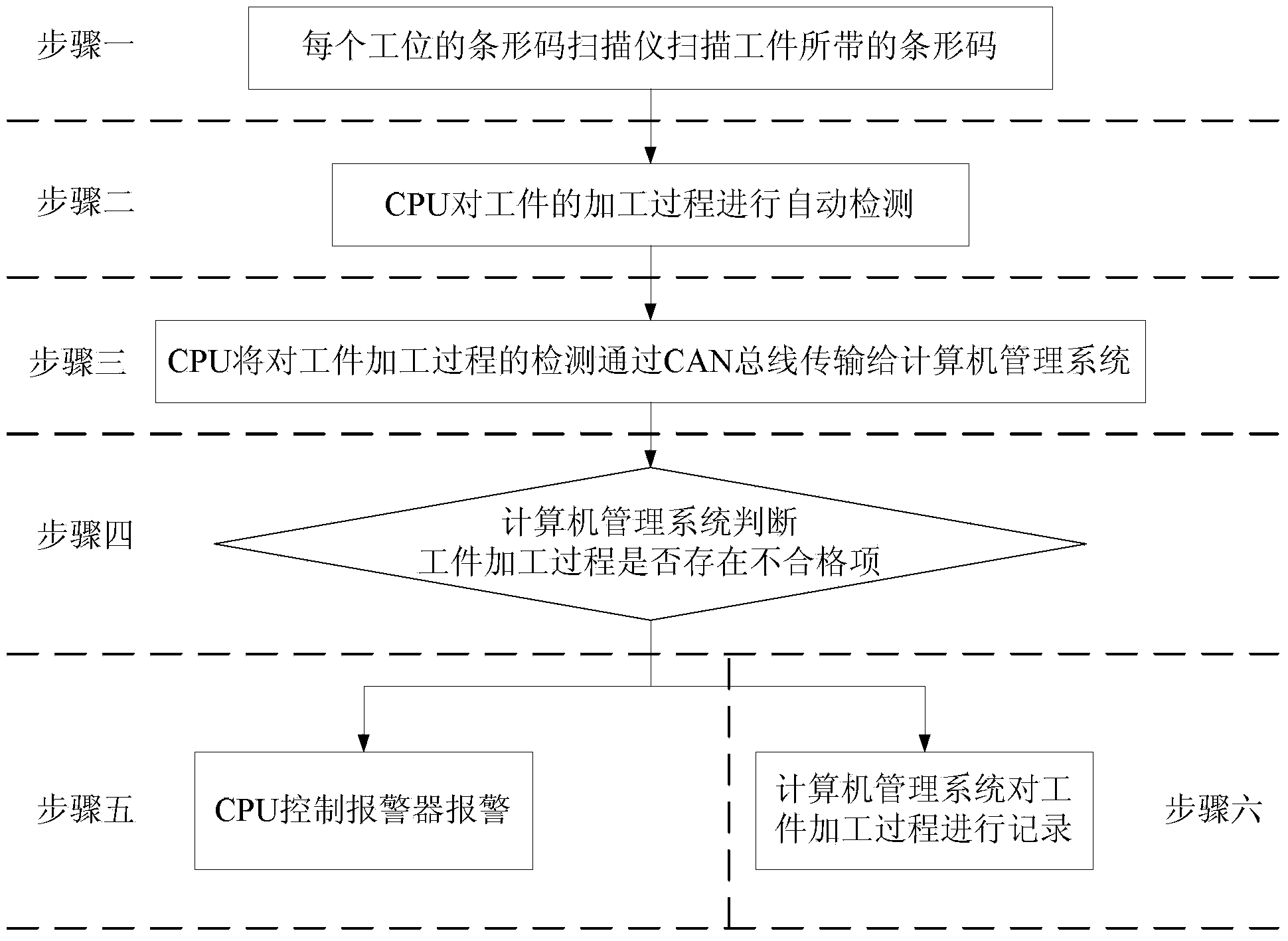

[0013] Specific implementation mode three: the following combination figure 2 Describe this embodiment, the error prevention management method based on the automobile meter production barcode error prevention management system described in this embodiment, the specific process of this method is:

[0014] Step 1, the bar code scanner 2 of each station scans the bar code carried by the workpiece;

[0015] Step 2, CPU6 automatically detects the machining process of the workpiece;

[0016] Step 3, CPU6 transmits the detection of the workpiece processing process to the computer management system through the CAN bus;

[0017] Step 4. The computer management system judges whether there are unqualified items in the workpiece processing process, if yes, execute step 5, otherwise execute step 6;

[0018] Step 5, CPU6 controls alarm 8 to report to the police;

[0019] Step 6: The computer management system records the workpiece processing.

[0020] Working method of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com